Filter by

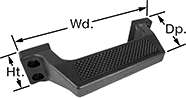

Step Tread

Width

Overall Width

Overall Depth

Landing Height Range

Depth

Landing Height

Weight Capacity

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Climbing Angle

Step Handles

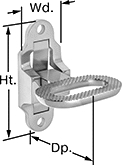

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Material | Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Color | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Plastic | 1 5/8" | 6 3/8" | 2 1/2" | 3 1/4" | 1 1/8" | Diamond Tread | 2 1/2" | 0.22 | Black | No | 4 | 1/4" | 3/4" | 5 1/2" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld On | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Steel | 1 3/4" | 7 3/4" | 4 1/8" | 6 3/4" | 1 5/8" | Diamond Tread | 4 1/8" | 3.2 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Aluminum | 1 5/8" | 7 3/4" | 4 1/8" | 7" | 1 5/8" | Diamond Tread | 4 1/8" | 1.12 | — | — | — | — | — | — | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

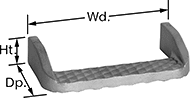

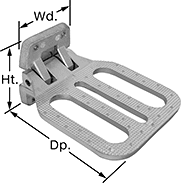

Fold-Up Steps

|  |

Style 1 | Style 2 |

|  |

Style 3 | Style 4 |

Style 1

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 3/4" | 3 3/4" | 4 3/8" | 2 1/8" | Diamond Tread | 3 3/4" | 2 | Not Rated | No | 2 | 5/16" | 3 7/8" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 3 1/2" | 6 5/8" | 6 1/2" | 5 1/4" | Diamond Tread | 6 5/8" | 4 | Not Rated | No | 2 | 5/16" | 3 7/8" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 3/4" | 3 3/4" | 4 3/8" | 2 1/8" | Diamond Tread | 3 3/4" | 2 | Not Rated | No | 2 | 5/16" | 3 7/8" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/8" | 1 7/8" | 3 1/2" | 3 3/8" | 2" | Diamond Tread | 3 1/2" | 1 | Not Rated | No | 2 | 5/16" | 3 5/8" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 2

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chrome-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 7/8" | 4" | 8 1/2" | 6 3/4" | 6 3/8" | Diamond Tread | 8 1/2" | 5 | Not Rated | No | 4 | 5/16" | 4" | 2 1/4" | Assembled | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style 3

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Ht. | Ctr.-to-Ctr. Wd. | Assembly | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 2 3/8" | 5 5/8" | 1" | 4 1/4" | Serrated | 5 5/8" | 1 | Not Rated | No | 4 | 3/16" | 2 5/8" | 1 3/4" | Assembled | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

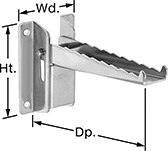

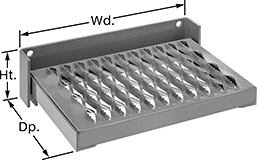

Style 4

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Wd. | Dp. | Tread | Projection | Wt., lb. | Wt. Cap., lb. | Mounting Hardware Included | No. of | Dia. | Ctr.-to-Ctr. Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gray Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 15" | 10 3/4" | 14 1/4" | 9 1/2" | Serrated | 10 3/4" | 11 | 350 | No | 2 | 9/16" | 13" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gray Powder-Coated Steel with Spring-Loaded Hinge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 15" | 10 3/4" | 14 1/4" | 9 1/2" | Serrated | 10 3/4" | 11 | 350 | No | 2 | 9/16" | 13" | Assembled | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Yellow Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 15" | 10 3/4" | 14 1/4" | 9 1/2" | Serrated | 10 3/4" | 11 | 350 | No | 2 | 9/16" | 13" | Assembled | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

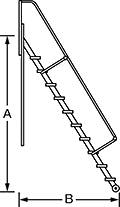

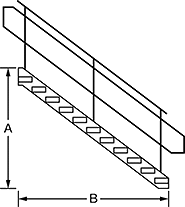

Foldaway Stairs

Manual

Overall | Step | Handrail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Landing Ht. (A), ft. | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Dp. | Tread | Wt. Cap., lb. | Ht. | Color | Mounting Hardware Included | Assembly | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24 1/4" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 33" | 43" | 58° | 7 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 33" | 50" | 58° | 8 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 33" | 58" | 58° | 9 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 33" | 65" | 58° | 10 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 33" | 73" | 58° | 11 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 33" | 80" | 58° | 13 | 7" | Serrated | 350 | 31 1/2" | Yellow | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric

Overall | Step | Handrail | Electrical | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Landing Ht. (A), ft. | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Dp. | Tread | Wt. Cap., lb. | Ht. | Color | Motor Input Voltage, V AC | Connection | No. of Blades | Mounting Hardware Included | Assembly | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

23 5/8" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 32" | 73" | 58° | 11 | 7" | Serrated | 350 | 32" | Yellow | 120 | Straight Blade | 3 | No | Unassembled | OSHA Compliant 29 CFR 1910.25 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

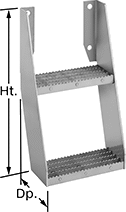

Wall-Mount Steps

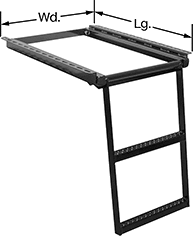

Under-Mount Foldaway Steps

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Climbing Ht. | Lg. | Wd. | Ladder Wd. | No. of Steps | Step Tread | Wt. Cap. | Mounting Hardware Included | No. of | Lg. | Wd. | Assembly | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 25 1/2" | 19 3/4" | 14 1/4" | 2 | Perforated | Not Rated | No | 28 | 1 3/16" | 3/8" | Assembled | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19" | 30 1/4" | 19 3/4" | 14 1/4" | 3 | Perforated | Not Rated | No | 32 | 1 3/16" | 3/8" | Assembled | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

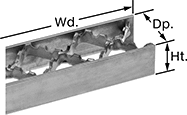

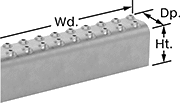

Ladder-Style Steps

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | Weight Capacity | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 7/8" | 540 lb. | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 20 ft. | 1 7/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 250 lb. for 18" to 24" Cut Lengths, 330 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 330 lb. for 18" to 24" Cut Lengths, 450 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 570 lb. for 18" to 24" Cut Lengths, 760 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 17" | 2" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 7 ft. | 2" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 5 ft. | 1 5/8" | 220 lb. for 18" to 24" Cut Lengths, 290 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 310 lb. for 18" to 24" Cut Lengths, 410 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 540 lb. for 18" to 24" Cut Lengths, 720 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Serrated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 17" | 1 1/8" | 540 lb. | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 7 ft. | 1 1/8" | 250 lb. for 18" to 24" Cut Lengths, 540 lb. Up to 18" Cut Lengths | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Perforated Step | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 1 1/4" | 230 lb. for 18" to 24" Cut Lengths, 300 lb. Up to 18" Cut Lengths | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 5 ft. | 2 1/4" | 380 lb. for 18" to 24" Cut Lengths, 510 lb. Up to 18" Cut Lengths | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Strut Channel Handles

|

Handle Shown Installed |

|

Mounting Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Ht. | Dia. | No. of | Mounting Fasteners Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For 1 5/8" Channel Width | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 5/8" | 1 5/8" | 9/16" | 2 | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

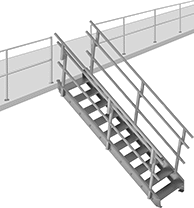

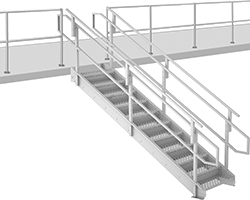

Top-Mount Stairs

|  |

OSHA Compliant | IBC Compliant |

|  |

Stair Risers |

Stairs | Stair Risers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Step | Handrail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Landing Ht. (A) | Wd. | Dp. (B) | Climbing Angle | No. of Steps | Dp. | Tread | Wt. Cap., lb. | Ht. | Color | Mounting Hardware Included | Assembly | Includes | Specs. Met | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

30" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38" to 44" | 43" | 39" to 43" | 35° to 42° | 4 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 000000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47" to 53" | 43" | 48" to 53" | 35° to 42° | 5 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 54" to 61" | 43" | 60" to 64" | 35° to 42° | 6 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62" to 69" | 43" | 69" to 75" | 35° to 42° | 7 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 70" to 78" | 43" | 79" to 85" | 35° to 42° | 8 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 79" to 86" | 43" | 90" to 93" | 35° to 42° | 9 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 87" to 95" | 43" | 99" to 105" | 35° to 42° | 10 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" to 104" | 43" | 109" to 115" | 35° to 42° | 11 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 105" to 113" | 43" | 119" to 125" | 35° to 42° | 12 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114" to 130" | 43" | 139" to 150" | 35° to 42° | 14 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Wide Steps | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 36" to 42" | 47" | 56" to 59" | 28° to 33° | 5 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 38" to 44" | 49" | 39" to 43" | 35° to 42° | 4 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 43" to 48" | 47" | 67" to 71" | 28° to 33° | 6 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 47" to 53" | 49" | 48" to 53" | 35° to 42° | 5 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 49" to 55" | 47" | 78" to 82" | 28° to 33° | 7 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 56" to 61" | 47" | 89" to 94" | 28° to 33° | 8 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62" to 69" | 49" | 69" to 75" | 35° to 42° | 7 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 62" to 70" | 47" | 100" to 106" | 28° to 33° | 9 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 72" to 84" | 47" | 121" to 129" | 28° to 33° | 11 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 85" to 98" | 47" | 144" to 153" | 28° to 33° | 13 | 11" | Perforated | 1,800 | 43 1/2" | Yellow | No | Unassembled | Stair Risers | IBC Compliant | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 96" to 104" | 49" | 109" to 115" | 35° to 42° | 11 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 114" to 130" | 49" | 139" to 150" | 35° to 42° | 14 | 9 1/2" | Perforated | 1,800 | 42" | Yellow | No | Unassembled | — | Cal/OSHA Compliant Title 8 Section 3214, Cal/OSHA Compliant Title 8 Section 3234, OSHA Compliant 29 CFR 1910.25, OSHA Compliant 29 CFR 1910.29 | 0000000 | 00000000 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

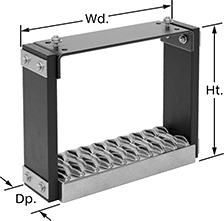

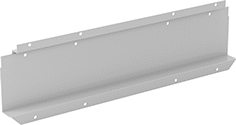

Under-Mount Steps

Overall | Step | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ht. | Wd. | Dp. | No. of Steps | Wd. | Dp. | Tread | Material | Wt. Cap. | Mounting Hardware Included | No. of | Dia. | Assembly | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Rubber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 13 1/2" | 4 3/4" | 1 | 12" | 4 3/4" | Serrated | Galvanized Steel | Not Rated | Yes | 2 | 3/8" | Unassembled | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 31 1/2" | 4 3/4" | 1 | 30" | 4 3/4" | Serrated | Galvanized Steel | Not Rated | Yes | 2 | 3/8" | Unassembled | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||