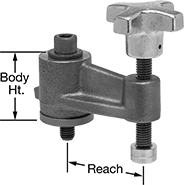

Hold-Down Fixture Clamps

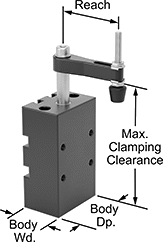

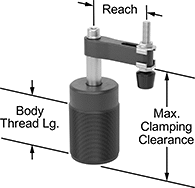

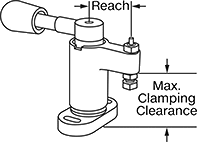

Tighten these clamps to hold your workpiece from above. They’re also known as swing clamps, since you can rotate the hook out of the way when the screw is loose. Install them in a drilled hole for maximum rigidity.

Clamps with a socket head screw are a good choice when you have limited vertical clearance. The screw is mounted nearly flush with the top of the clamp.

Clamps with a cap nut tighten and loosen by hand, so you don’t need tools.

Add mounting blocks to rotate the clamp’s hook consistently—these blocks have a stop every 90°. They’re also useful if you don’t have an easy mounting location for the fixture clamp.

Clamps | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Thread | Drive | Mounting Blocks | ||||||||||

| Max. Clamping Clearance | Holding Capacity, lbs. | Reach | Lg. | Dia. | Size | Lg. | Size | Style | Material | Each | Each | ||

Socket Head Screw | |||||||||||||

| 7/8" | 4,800 | 11/16" | 1 3/8" | 5/8" | 5/16"-18 | 1 3/4" | 1/4" | Hex | Black-Oxide Steel | 0000000 | 000000 | 000000 | 00 |

| 29/32" | 2,200 | 1 3/16" | 1 3/8" | 3/4" | 5/16"-18 | 2" | 1/4" | Hex | Black-Oxide Steel | 0000000 | 00000 | 0000000 | 000000 |

| 1 17/32" | 2,700 | 2 3/8" | 2 1/4" | 1" | 1/2"-13 | 3" | 3/8" | Hex | Black-Oxide Steel | 0000000 | 00000 | 0000000 | 00000 |

| 1 17/32" | 3,700 | 2 3/8" | 2 3/8" | 1 1/4" | 5/8"-11 | 3 1/4" | 1/2" | Hex | Black-Oxide Steel | 0000000 | 000000 | 0000000 | 000000 |

| 1 5/8" | 6,400 | 1" | 2 1/4" | 7/8" | 3/8"-16 | 3" | 5/16" | Hex | Black-Oxide Steel | 0000000 | 00000 | 000000 | 00 |

| 1 5/8" | 12,000 | 1" | 2 1/4" | 7/8" | 1/2"-13 | 3" | 3/8" | Hex | Black-Oxide Steel | 0000000 | 00000 | 000000 | 00 |

| 1 13/16" | 17,000 | 1 7/16" | 2 3/4" | 1 1/8" | 5/8"-11 | 3 1/2" | 1/2" | Hex | Black-Oxide Steel | 0000000 | 00000 | 000000 | 00 |

Knob Head Screw with Cap Nut | |||||||||||||

| 7/8" | Not Rated | 11/16" | 1 3/8" | 5/8" | 5/16"-18 | 2 1/2" | 5/8" | External Hex | Black-Oxide Steel | 00000000 | 00000 | 000000 | 00 |

| 1 5/8" | Not Rated | 1" | 2 1/4" | 7/8" | 3/8"-16 | 4" | 3/4" | External Hex | Black-Oxide Steel | 00000000 | 00000 | 000000 | 00 |

| 1 5/8" | Not Rated | 1" | 2 1/4" | 7/8" | 1/2"-13 | 4" | 7/8" | External Hex | Black-Oxide Steel | 00000000 | 00000 | 000000 | 00 |

Air-Powered Hold-Down Fixture Clamps for Welding

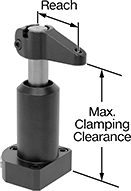

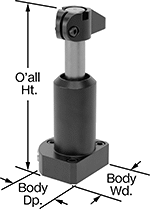

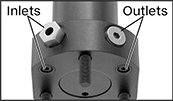

Compact and lightweight, these clamps are easy to move and reposition when welding. Adjust the air pressure to quickly and consistently clamp or release parts. When pressure is applied, the arm on these clamps rotates 90° into position over your workpiece before clamping down. When pressure is released, the arm rises and rotates out of the way, so you can load or unload parts. They’re also known as swing clamps. Attach a sensor (not included) to activate relays and controllers. Connect their ports to a control valve and an air line. Use screws (not included) to mount the base to a flat surface.

All clamps come with a holding screw. Screws with a rubber tip are nonmarring, and their tip is removable.

Replacement clamping arms (sold separately) do not include a holding screw. Extended clamping arms (sold separately) give your clamp a longer reach than standard arms. However, you’ll have to use lower pressure, which means the actual clamping force will be lower than the clamp’s listed rating.

Add a clamping arm adapter (sold separately) to mount your own custom-machined arm.

Fixture Clamps | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Holding Screw | Female Air Inlet and Outlet | Mount. Holes | Replacement Clamping Arms | Extended Clamping Arms | Clamping Arm Adapters | |||||||||||||||||||||

| Max. Clamping Clearance | Vertical Travel During Rotation | Max. Clamping Stroke | Holding Cap., lbs. | Reach | Wd. | Dp. | O'all Ht. | Thread Size | Tip Material | Pipe Size | Thread Size | Thread Type | No of. | Dia. | Thread Size | Dp. | Location | Material | Each | Each | Lg. | Each | Each | ||||

90° Clockwise Rotation | |||||||||||||||||||||||||||

| 3 5/8" | 21/32" | 5/16" | 20 | 1 5/8" | 1 1/8" | 1 5/8" | 4" | M4 × 0.7 mm | Rubber | __ | M5 × 0.8 mm | Metric | 4 2 | __ | M5 × 0.8 mm M5 × 0.8 mm | — 9/16" | Side Base | Aluminum | 000000000 | 0000000 | 000000000 | 000000 | __ | 000000 | 00 | 000000000 | 000000 |

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/4" | 1 1/4" | 4 3/4" | 10-32 | Steel | __ | 10-32 | UNF | 4 2 | 3/16" 3/16" | __ | __ | Side Base | Aluminum | 00000000 | 000000 | 000000000 | 00000 | 2 7/8" | 000000000 | 000000 | 000000000 | 00000 |

| 4 7/8" | 1 3/16" | 9/16" | 100 | 2 9/16" | 2 3/16" | 2 3/4" | 5 5/8" | M8 × 1.25 mm | Rubber | 1/8 | __ | BSPP | 4 4 2 | __ | M8 × 1.25 mm M8 × 1.25 mm M8 × 1.25 mm | 3/4" 9/16" 9/16" | Base Side Side | Aluminum | 000000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000000 | 00000 |

| 5 1/2" | 3/4" | 1/2" | 130 | 2" | 2" | 3" | 6 3/8" | 3/8"-16 | Rubber | 1/8 | __ | NPT | 4 2 | 11/32" 11/32" | __ | __ | Side Base | Aluminum | 00000000 | 000000 | 000000000 | 00000 | 3 3/4" | 000000000 | 00000 | 000000000 | 00000 |

90° Counterclockwise Rotation | |||||||||||||||||||||||||||

| 3 5/8" | 21/32" | 5/16" | 20 | 1 5/8" | 1 1/8" | 1 5/8" | 4" | M4 × 0.7 mm | Rubber | __ | M5 × 0.8 mm | Metric | 4 2 | __ | M5 × 0.8 mm M5 × 0.8 mm | — 9/16" | Side Base | Aluminum | 000000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000000 | 00000 |

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/4" | 1 1/4" | 4 3/4" | 10-32 | Steel | __ | 10-32 | UNF | 4 2 | 3/16" 3/16" | __ | __ | Side Base | Aluminum | 00000000 | 000000 | 000000000 | 00000 | 2 7/8" | 000000000 | 00000 | 000000000 | 00000 |

| 4 7/8" | 1 3/16" | 9/16" | 100 | 2 9/16" | 2 3/16" | 2 3/4" | 5 5/8" | M8 × 1.25 mm | Rubber | 1/8 | __ | BSPP | 4 4 2 | __ | M8 × 1.25 mm M8 × 1.25 mm M8 × 1.25 mm | 3/4" 9/16" 9/16" | Base Side Side | Aluminum | 000000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000000 | 00000 |

| 5 1/2" | 3/4" | 1/2" | 130 | 2" | 2" | 3" | 6 3/8" | 3/8"-16 | Rubber | 1/8 | __ | NPT | 4 2 | 11/32" 11/32" | __ | __ | Side Base | Aluminum | 00000000 | 000000 | 000000000 | 00000 | 3 3/4" | 000000000 | 00000 | 000000000 | 00000 |

| For Max. Clamping Clearance | Includes | Each | |

| 4 3/8" | Rod Seal, Rod Wiper, End Cap Seal, Retaining Ring, Aluminum Piston with a Molded Seal and Groove with a Magnetic Ring | 000000000 | 000000 |

| 5 1/2" | Rod Seal, Rod Wiper, End Cap Seal, Retaining Ring, Aluminum Piston with a Molded Seal and Groove with a Magnetic Ring | 000000000 | 00000 |

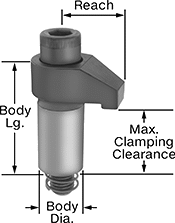

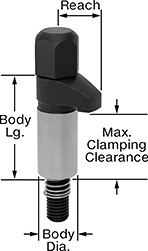

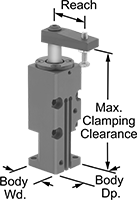

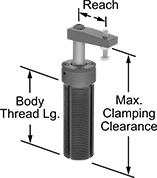

Threaded Air-Powered Hold-Down Fixture Clamps for Welding

Screw these clamps directly into a tapped hole and use air pressure to quickly and consistently clamp and release parts when welding. Compact and lightweight, these clamps are easy to move and reposition when welding. They’re also known as swing clamps. Connect these clamps to a control valve and air line. When pressure is applied, the arm on these clamps rotates 90° into position over your workpiece before clamping down. When pressure is released, the arm rises and rotates out of the way, so you can load or unload parts.

Sensor-ready clamps activate relays and controllers when used with a sensor (not included).

Clamps with a rubber-tipped holding screw are nonmarring. Their tip is removable.

Replacement clamping arms do not include a holding screw. Extended clamping arms give your clamp a longer reach than standard arms. However, you’ll have to use lower pressure, which means the actual clamping force will be lower than the clamp’s listed rating.

Add a clamping arm adapter to mount your own custom-machined arm.

Use mounting blocks (sold separately) to hold clamps in an untapped hole.

Fixture Clamps | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Holding Screw | Female Air Inlet and Outlet | Replacement Clamping Arms | Extended Clamping Arms | Clamping Arm Adapters | |||||||||||||||||||||

| Max. Clamping Clearance | Vertical Travel During Rotation | Max. Clamping Stroke | Holding Cap., lbs. | Reach | Thread Size | Thread Pitch, mm | Thread Lg. | Sensor Ready | O'all Ht. | Thread Size | Thread Pitch, mm | Tip Material | Pipe Size | Thread Size | Thread Pitch, mm | Thread Type | Material | Each | Each | Lg. | Each | Each | ||||

90° Clockwise Rotation | ||||||||||||||||||||||||||

| 4" | 1 3/32" | 17/32" | 35 | 1 15/16" | M40 | 1.5 | 1 11/16" | Not Sensor Ready | 4 5/8" | M6 | 1 | Rubber | __ | M5 | 0.8 | Metric | Aluminum | 0000000 | 0000000 | 0000000 | 000000 | __ | 000000 | 00 | 0000000 | 000000 |

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/8"-16 | __ | 2 7/8" | Sensor Ready | 4 3/4" | 10-32 | __ | Steel | __ | 10-32 | __ | UNF | Aluminum | 00000000 | 000000 | 000000000 | 00000 | 2 7/8" | 000000000 | 000000 | 000000000 | 00000 |

| 4 9/16" | 1 1/8" | 17/32" | 100 | 2 9/16" | M55 | 1.5 | 2 1/4" | Not Sensor Ready | 5 1/4" | M8 | 1.25 | Rubber | 1/8 | __ | __ | BSPP | Aluminum | 0000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000000 | 00000 |

| 5 5/16" | 3/4" | 1/2" | 95 | 1 5/8" | 1 3/4"-12 | __ | 3 1/4" | Sensor Ready | 6 1/8" | 3/8"-16 | __ | Rubber | 1/8 | __ | __ | NPT | Aluminum | 00000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000 | 00 |

90° Counterclockwise Rotation | ||||||||||||||||||||||||||

| 4" | 1 3/32" | 17/32" | 35 | 1 15/16" | M40 | 1.5 | 1 11/16" | Not Sensor Ready | 4 5/8" | M6 | 1 | Rubber | __ | M5 | 0.8 | Metric | Aluminum | 0000000 | 000000 | 0000000 | 00000 | __ | 000000 | 00 | 0000000 | 00000 |

| 4 3/8" | 15/32" | 3/8" | 35 | 1 1/8" | 1 1/8"-16 | __ | 2 7/8" | Sensor Ready | 4 3/4" | 10-32 | __ | Steel | __ | 10-32 | __ | UNF | Aluminum | 00000000 | 000000 | 000000000 | 00000 | 2 7/8" | 000000000 | 00000 | 000000000 | 00000 |

| 4 9/16" | 1 1/8" | 17/32" | 100 | 2 9/16" | M55 | 1.5 | 2 1/4" | Not Sensor Ready | 5 1/4" | M8 | 1.25 | Rubber | 1/8 | __ | __ | BSPP | Aluminum | 0000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000000 | 00000 |

| 5 5/16" | 3/4" | 1/2" | 95 | 1 5/8" | 1 3/4"-12 | __ | 3 1/4" | Sensor Ready | 6 1/8" | 3/8"-16 | __ | Rubber | 1/8 | __ | __ | NPT | Aluminum | 00000000 | 000000 | 000000000 | 00000 | __ | 000000 | 00 | 000000 | 00 |

| For Max. Clamping Clearance | Includes | Each | |

| 4 3/8" | Rod Seal, Rod Wiper, End Cap Seal, Retaining Ring, Aluminum Piston with a Molded Seal and Groove with a Magnetic Ring | 000000000 | 000000 |

| 5 5/16" | Rod Seal, Rod Wiper, End Cap Seal, Retaining Ring, Aluminum Piston with a Molded Seal and Groove with a Magnetic Ring | 0000000 | 000000 |

Hold-Down Fixture Clamps with Handle

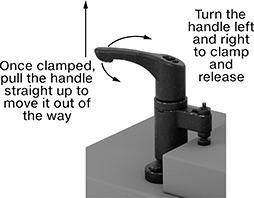

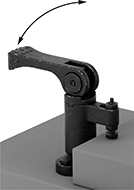

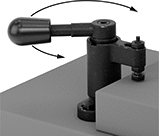

Turn or flip a handle to secure or release your material—no tools required. These clamps are easier to set up than other hold-down clamps, so they’re good for frequently swapping fixtures or using multiple clamps at once. Also known as swing clamps, they have a rotating clamping arm that can be moved out of the way when the clamp is not engaged.

Adjustable handles turn left and right to clamp and release. After engaging the clamp, you can pull the handle straight up to move it out of the way. You'll feel the handle disengage—that means you can rotate it freely while maintaining your clamp.

Cam handles flip down to clamp and up to release, so it’s easy to see if your material is secured.

Lever handles clamp with a turn to the left or the right.

Overall | Mount. Holes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Clamping Clearance | Max. Clamping Stroke | Holding Cap., lbs. | Reach | Ht. | Wd. | Dp. | Mounting Fasteners Included | No. of | Dia. | Material | Each | |

70° Clockwise Rotation | ||||||||||||

Adjustable Handle | ||||||||||||

| 13/32" | 1/8" | 445 | 7/8" | 2 7/8" | 1 7/16" | 2 5/8" | No | 2 | 5/32" | Black-Oxide Steel | 0000000 | 0000000 |

| 9/16" | 5/32" | 715 | 1 3/16" | 3 7/8" | 1 3/4" | 3 15/16" | No | 2 | 7/32" | Black-Oxide Steel | 0000000 | 000000 |

| 23/32" | 5/32" | 1,000 | 1 7/16" | 4 13/16" | 2 9/16" | 4 15/16" | No | 2 | 5/16" | Black-Oxide Steel | 0000000 | 000000 |

| 7/8" | 3/16" | 1,300 | 1 3/4" | 5 3/4" | 3 3/8" | 5 15/16" | No | 2 | 13/32" | Black-Oxide Steel | 0000000 | 000000 |

Cam Handle | ||||||||||||

| 1 3/16" | 1/32" | 175 | 7/8" | 4" | 1 7/16" | 3" | No | 2 | 5/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 9/16" | 1/32" | 335 | 1 3/16" | 5 3/16" | 1 3/4" | 3 7/8" | No | 2 | 7/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 15/16" | 3/64" | 470 | 1 7/16" | 6 9/16" | 2 9/16" | 4 15/16" | No | 2 | 5/16" | Black-Oxide Steel | 0000000 | 000000 |

| 2 11/32" | 1/16" | 625 | 1 3/4" | 8 3/16" | 3 3/8" | 6 1/8" | No | 2 | 13/32" | Black-Oxide Steel | 0000000 | 000000 |

Lever Handle | ||||||||||||

| 1 3/16" | 1/32" | 245 | 7/8" | 1 15/16" | 1 7/16" | 3" | No | 2 | 5/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 9/16" | 3/64" | 400 | 1 3/16" | 2 5/8" | 1 3/4" | 3 7/8" | No | 2 | 7/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 15/16" | 1/16" | 490 | 1 7/16" | 3 1/4" | 2 9/16" | 4 15/16" | No | 2 | 5/16" | Black-Oxide Steel | 0000000 | 000000 |

| 2 11/32" | 5/64" | 785 | 1 3/4" | 3 15/16" | 3 3/8" | 6 1/8" | No | 2 | 13/32" | Black-Oxide Steel | 0000000 | 000000 |

70° Counterclockwise Rotation | ||||||||||||

Adjustable Handle | ||||||||||||

| 13/32" | 1/8" | 445 | 7/8" | 2 7/8" | 1 7/16" | 2 5/8" | No | 2 | 5/32" | Black-Oxide Steel | 0000000 | 000000 |

| 9/16" | 5/32" | 715 | 1 3/16" | 3 7/8" | 1 3/4" | 3 15/16" | No | 2 | 7/32" | Black-Oxide Steel | 0000000 | 000000 |

| 23/32" | 5/32" | 1,000 | 1 7/16" | 4 13/16" | 2 9/16" | 4 15/16" | No | 2 | 5/16" | Black-Oxide Steel | 0000000 | 000000 |

| 7/8" | 3/16" | 1,300 | 1 3/4" | 5 3/4" | 3 3/8" | 5 15/16" | No | 2 | 13/32" | Black-Oxide Steel | 0000000 | 000000 |

Cam Handle | ||||||||||||

| 1 3/16" | 1/32" | 175 | 7/8" | 4" | 1 7/16" | 3" | No | 2 | 5/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 9/16" | 1/32" | 335 | 1 3/16" | 5 3/16" | 1 3/4" | 3 7/8" | No | 2 | 7/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 15/16" | 3/64" | 470 | 1 7/16" | 6 9/16" | 2 9/16" | 4 15/16" | No | 2 | 5/16" | Black-Oxide Steel | 0000000 | 000000 |

| 2 11/32" | 1/16" | 625 | 1 3/4" | 8 3/16" | 3 3/8" | 6 1/8" | No | 2 | 13/32" | Black-Oxide Steel | 0000000 | 000000 |

Lever Handle | ||||||||||||

| 1 3/16" | 1/32" | 245 | 7/8" | 1 15/16" | 1 7/16" | 3" | No | 2 | 5/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 9/16" | 3/64" | 400 | 1 3/16" | 2 5/8" | 1 3/4" | 3 7/8" | No | 2 | 7/32" | Black-Oxide Steel | 0000000 | 000000 |

| 1 15/16" | 1/16" | 490 | 1 7/16" | 3 1/4" | 2 9/16" | 4 15/16" | No | 2 | 5/16" | Black-Oxide Steel | 0000000 | 000000 |

| 2 11/32" | 5/64" | 785 | 1 3/4" | 3 15/16" | 3 3/8" | 6 1/8" | No | 2 | 13/32" | Black-Oxide Steel | 0000000 | 000000 |

Hydraulic Hold-Down Fixture Clamps

Best for CNC milling, these clamps combine 10 times the force of air-powered clamps with automated swing action for fast, secure workholding. Their clamping arm (sold separately) rotates up and out of the way when not engaged, so you can easily insert and remove your workpiece.

Connect your hydraulic line to the back or the bottom of the clamp. All ports are sealed with an O-ring and a screw; unseal the port you want to use.

Single-acting clamps only use pressure to clamp down on a workpiece. When you release the pressure, a spring returns the clamping arm to its original position. They’re a good choice for simple setups, where you only need one or two clamps.

Double-acting clamps use pressure both to clamp and release a workpiece, giving you precise control over the process. They’re more efficient than single-acting clamps, since their release is quicker and more predictable. They’re a good choice if you need to coordinate the action of multiple clamps.

Choose a clamping arm best suited for your application. Machinable clamping arms let you customize the length and shape to suit your application. Because they are longer than standard arms, you’ll have to use lower pressure, and their actual clamping force will be lower than the listed rating.

Maximum clamping stroke is the vertical distance a clamping arm can travel to clamp a workpiece.

Clamps | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Body | Female Inlet and Outlet | Clamping Arms | Machinable Clamping Arms | |||||||||||||||

| Max. Clamping Clearance | Max. Clamping Stroke | O'all Ht. | Max. Clamping Force, lbs. | Wd. | Dp. | Thread Type | Thread Size | Mount. Fasteners Included | Material | Each | Lg. | Reach | Each | Lg. | Each | |||

Single Acting | ||||||||||||||||||

90° Clockwise Rotation | ||||||||||||||||||

| 4 9/16" | 3/8" | 5 5/16" | 1,100 | 2 1/4" | 2 1/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 0000000 | 2 3/8" | 1 9/16" | 00000000 | 0000000 | 5 13/16" | 00000000 | 0000000 |

| 5 9/16" | 1/2" | 6 3/4" | 2,400 | 2 7/8" | 2 5/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 3 1/8" | 2" | 00000000 | 000000 | 7 1/16" | 00000000 | 000000 |

| 6 3/16" | 5/8" | 8 7/8" | 7,450 | 3 1/2" | 3 15/16" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 00000000 | 4 5/8" | 2 11/16" | 00000000 | 000000 | 8 1/2" | 00000000 | 000000 |

90° Counterclockwise Rotation | ||||||||||||||||||

| 4 9/16" | 3/8" | 5 5/16" | 1,100 | 2 1/4" | 2 1/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 2 3/8" | 1 9/16" | 00000000 | 000000 | 5 13/16" | 00000000 | 000000 |

| 5 9/16" | 1/2" | 6 3/4" | 2,400 | 2 7/8" | 2 5/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 3 1/8" | 2" | 00000000 | 000000 | 7 1/16" | 00000000 | 000000 |

| 6 3/16" | 5/8" | 8 7/8" | 7,450 | 3 1/2" | 3 15/16" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 00000000 | 4 5/8" | 2 11/16" | 00000000 | 000000 | 8 1/2" | 00000000 | 000000 |

Double Acting | ||||||||||||||||||

90° Clockwise Rotation | ||||||||||||||||||

| 4 9/16" | 3/8" | 5 5/16" | 1,250 | 2 1/4" | 2 1/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 2 3/8" | 1 9/16" | 00000000 | 000000 | 5 13/16" | 00000000 | 000000 |

| 5 9/16" | 1/2" | 6 3/4" | 2,600 | 2 7/8" | 2 5/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 3 1/8" | 2" | 00000000 | 000000 | 7 1/16" | 00000000 | 000000 |

| 6 3/16" | 5/8" | 7 3/4" | 7,600 | 3 1/2" | 3 15/16" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 00000000 | 4 5/8" | 2 11/16" | 00000000 | 000000 | 8 1/2" | 00000000 | 000000 |

90° Counterclockwise Rotation | ||||||||||||||||||

| 4 9/16" | 3/8" | 5 5/16" | 1,250 | 2 1/4" | 2 1/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 2 3/8" | 1 9/16" | 00000000 | 000000 | 5 13/16" | 00000000 | 000000 |

| 5 9/16" | 1/2" | 6 3/4" | 2,600 | 2 7/8" | 2 5/8" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 000000 | 3 1/8" | 2" | 00000000 | 000000 | 7 1/16" | 00000000 | 000000 |

| 6 3/16" | 5/8" | 7 3/4" | 7,600 | 3 1/2" | 3 15/16" | UN/UNF (SAE Straight) | 7/16"-20 | Yes | Steel | 00000000 | 00000000 | 4 5/8" | 2 11/16" | 00000000 | 000000 | 8 1/2" | 00000000 | 000000 |

Light Duty Fixture Clamp Kits

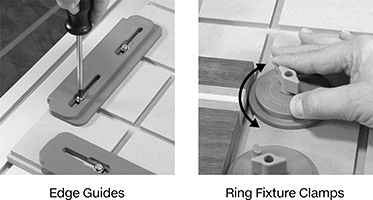

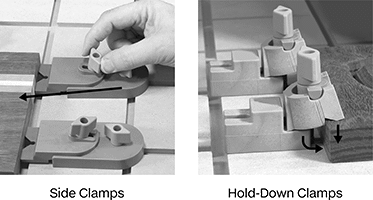

Made of plastic, the clamps in these kits are used for woodworking and other machining jobs that don’t need high clamping pressure. Each kit comes with edge guides and three different types of clamps, so you can secure workpieces of all shapes and sizes. Edge guides are often used as a frame to consistently position multiple workpieces for repeat jobs. Ring fixture clamps tighten with a twist—they press into the side of your workpiece to hold it in place. Side clamps apply force both inward and downward without blocking the top of your workpiece. Hold-down clamps grip the top and side of your workpiece for the most secure hold.

| No. of Pieces | Includes | Material | Mounting Screw Thread Size | Each | |

| 12 | 3 Edge Guides, 2 Ring Fixture Clamps, 2 Side Clamps, 4 Hold-Down Clamps, Nylon Mounting Hardware | Plastic | 1/4"-20 | 0000000 | 0000000 |

Revolving Screw Clamps

When loosened, you can spin the body of this clamp around its mounting point for better access to the workpiece. Position over your workpiece and turn the handle to clamp down. Mount the clamp in a threaded hole or on a mounting base (sold separately).