Choosing an Electrical Switch

More

Limit Switches

When a moving object contacts the actuator on these switches, they open or close a circuit. They have the rapid-closing action of a snap-acting switch, but with a larger actuator. This makes them a good choice for use with large objects—for instance, a box on a conveyor runs into the switch, stopping the conveyor.

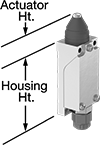

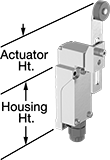

Switches with a plunger actuator require a push to actuate, similar to a button.

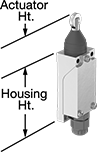

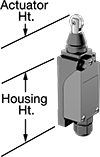

Switches with a roller plunger or cross roller plunger actuator have a roller that moves when an object pushes the actuator. This reduces friction during actuation to limit wear and tear on your switch. On cross roller plungers, the roller moves perpendicular to the mounting direction.

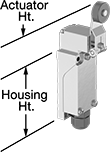

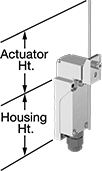

Switches with a roller lever actuator use a lever with a roller at the end to activate. This allows parts to glide across the actuation surface with minimal friction, limiting wear and tear on your switch.

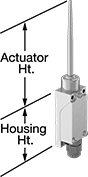

Switches with a rod actuator use a rod extending out of the body to actuate, so they’ll activate even if an object is far away.

Switches with a wobble stick actuator have an arm that rotates 360°, so you don’t need to align it in a specific direction. Since the actuator is flexible, it won’t snap if pushed backward. That makes these switches a great choice for systems that get jammed often.

Styles E and F let you adjust the actuator’s height to align it with your target.

Switches rated NEMA 13 are protected against dirt and oil/coolant spraying. Switches rated IP67 are protected against dust and temporary submersion.

Housing | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | No. of Circuits Controlled | Switch Starting Position | Switch Action | Industry Designation | Switching Current @ Voltage | Max. Voltage | Operating Temp. Range, °F | Actuator Ht. | Lg. | Ht. | Dp. | Housing Material | Environmental Rating | Each | |

Plunger Actuator Style | |||||||||||||||

With Screw Terminals | |||||||||||||||

| A | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 0.9" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 000000 |

Roller Plunger Actuator Style | |||||||||||||||

With Screw Terminals | |||||||||||||||

| B | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 1.3" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 00000 |

Cross Roller Plunger Actuator Style | |||||||||||||||

With Screw Terminals | |||||||||||||||

| C | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 1.5" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 00000 |

Roller Lever Actuator Style | |||||||||||||||

With Screw Terminals | |||||||||||||||

| D | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 1.9" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 00000 |

| E | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 1.9"-3.4" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 00000 |

Rod Actuator Style | |||||||||||||||

With Screw Terminals | |||||||||||||||

| F | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 1.5"-5" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 00000 |

Wobble Stick Actuator Style | |||||||||||||||

With Screw Terminals | |||||||||||||||

| H | 1 | 1 Off (Normally Open) or 1 On (Normally Closed) | Springs Back (Momentary) | SPDT | 0.5 A @ 380 V AC, 220 V DC | 380V AC 220V DC | -4° to 158° | 3.8" | 1.1" | 2.5" | 1" | Zinc | NEMA 13, IP67 | 000000 | 00000 |

Solid State Screw Terminal Relays

With no moving parts, these solid-state relays are fast switching and require less maintenance, last longer, and are quieter than mechanical switches.

Relays with high-starting-current protection are designed with integrated circuits that prevent damage from the large burst of electricity when a device, such as a motor or pump, turns on.

Heat sinks disperse heat to increase the relay’s current rating. Mount them to 35 mm DIN rail (also known as DIN 3 rail) for fast installation. They also mount to flat surfaces. Before mounting one-circuit relays, silicone compound or a thermal pad should be placed between the heat sink and relay. Silicone compound is sold separately for heat sinks that do not include it but require it. Two-circuit relays don’t require silicone for mounting.

Relays | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Switching Current | Heat Sinks | |||||||||||

| Number of Terminals | Input Voltage | Without Heat Sink | With Heat Sink | Switching Voltage | Max. Switching Voltage | Ht. | Wd. | Dp. | Each | Each | ||

1 Circuit Controlled with 1 Off (Normally Open)—SPST-NO | ||||||||||||

Relays with High-Starting-Current Protection | ||||||||||||

| 4 | 3V DC, 6V DC, 12V DC, 24V DC, 30V DC | 7A | 25A | 380V AC | 420V AC | 2.3" | 1.8" | 1" | 00000000 | 000000 | 0000000 | 0000000 |

| 4 | 3V DC, 6V DC, 12V DC, 24V DC, 30V DC | 11A | 45A | 380V AC | 420V AC | 2.3" | 1.8" | 1" | 00000000 | 000000 | 0000000 | 000000 |