Filter by

For Use On

For Use With

Mixer Speed

Shaft Material

Motor Type

Overall Height

Propeller Material

Direction of Operation

Current

Motor Enclosure Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

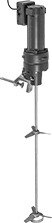

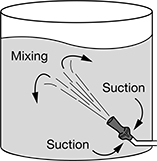

Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Features | Mount Type | Motor Enclosure Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 4.4 amp/2.2 amp | 60 | 51" | 48 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 4.4 amp/2.2 amp | 60 | 63" | 49 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 1 | 4 1/2" | 316 Stainless Steel | 32" | 5/8" | 6 amp/3 amp | 60 | 45 1/2" | 53 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 6 amp/3 amp | 60 | 61 1/2" | 54 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 60" | 5/8" | 6 amp/3 amp | 60 | 73 1/2" | 59 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 48" | 3/4" | 7.4 amp/3.7 amp | 60 | 61 1/2" | 61 | 3" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 60" | 3/4" | 8.4 amp/4.2 amp | 60 | 73 1/2" | 68 | 3" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1,725 | 2 | 4" | 316 Stainless Steel | 48" | 3/4" | 10.8 amp/5.4 amp | 60 | 70 1/4" | 66 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 350 | 1 | 7 5/8" | 316 Stainless Steel | 36" | 3/4" | 4.4 amp/2.2 amp | 60 | 53 5/8" | 59 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 350 | 1 | 10" | 316 Stainless Steel | 48" | 3/4" | 4.4 amp/2.2 amp | 60 | 65 5/8" | 63 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 1 | 6" | 316 Stainless Steel | 32" | 3/4" | 6.6 amp/3.3 amp | 60 | 49 5/8" | 52 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 1 | 11 3/16" | 316 Stainless Steel | 48" | 3/4" | 6 amp/3 amp | 60 | 65 5/8" | 63 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 2 | 7 5/8" | 316 Stainless Steel | 36" | 3/4" | 6 amp/3 amp | 60 | 53 5/8" | 60 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 2 | 10" | 316 Stainless Steel | 60" | 3/4" | 6 amp/3 amp | 60 | 77 5/8" | 67 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 350 | 2 | 10" | 316 Stainless Steel | 48" | 3/4" | 8 amp/4 amp | 60 | 66 1/2" | 62 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 350 | 2 | 11" | 316 Stainless Steel | 60" | 3/4" | 10.8 amp/5.4 amp | 60 | 78 3/4" | 71 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1,725 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 1.3 amp/0.7 amp | 60 | 51" | 48 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1,725 | 2 | 3 13/16" | 316 Stainless Steel | 48" | 3/4" | 3 amp/1.5 amp | 60 | 61 1/2" | 72 | 3" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1,725 | 2 | 5" | 316 Stainless Steel | 60" | 1" | 3.8 amp/1.9 amp | 60 | 81 3/4" | 76 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 1 | 6" | 316 Stainless Steel | 32" | 3/4" | 1.6 amp/0.8 amp | 60 | 49 3/8" | 61 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 1 | 11 3/16" | 316 Stainless Steel | 48" | 3/4" | 1.6 amp/0.8 amp | 60 | 65 5/8" | 63 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 350 | 2 | 10" | 316 Stainless Steel | 60" | 3/4" | 1.6 amp/0.8 amp | 60 | 77 5/8" | 67 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 350 | 2 | 11 3/16" | 316 Stainless Steel | 48" | 3/4" | 3 amp/1.5 amp | 60 | 65 5/8" | 66 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 350 | 2 | 11 13/16" | 316 Stainless Steel | 60" | 3/4" | 3 amp/1.5 amp | 60 | 77 5/8" | 68 | 3" | High-Flow Propeller | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 350 | 2 | 13" | 316 Stainless Steel | 60" | 1" | 5 amp/2.5 amp | 60 | 78 3/4" | 79 | 4" | — | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clamp-Mount Air-Powered Mixers for Tanks

Mixers | Replacement Air-Powered Motors | Replacement Mixer Propellers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Propellers | Shaft | Air Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Overall Ht. | Wt., lb. | Max. Clamp Opening | Includes | Mount Type | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 1 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 33" | 28 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 000000000 | 000000000 | 0000000 | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 1 | 6" | 316 Stainless Steel | 36" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 42" | 28 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 1 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 54" | 37 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 33" | 30 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 36" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 42" | 30 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 54" | 39 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 27" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 34 5/16" | 35 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 43 5/16" | 39 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 55 5/16" | 40 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 67 5/16" | 52 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 2 | 8" | 316 Stainless Steel | 36" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 43 5/16" | 41 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 2 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 55 5/16" | 42 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 2 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 67 5/16" | 55 | 1 7/8" | Needle Valve | Clamp On | 00000000 | 00000000 | 000000000 | 00000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 0 to 400 | 2 | 9" | 316 Stainless Steel | 30" | 3/4" | 1/4 | NPT | Female | 13 ft³/min @ 80 psi | 44" | 40 | 2 1/4" | Needle Valve | Clamp On | 0000000 | 00000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 0 to 400 | 2 | 11" | 316 Stainless Steel | 40" | 3/4" | 1/4 | NPT | Female | 25 ft³/min @ 80 psi | 55" | 52 | 2 1/4" | Needle Valve | Clamp On | 0000000 | 00000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 0 to 400 | 2 | 13" | 316 Stainless Steel | 48" | 1" | 1/2 | NPT | Female | 89 ft³/min @ 80 psi | 69" | 101 | 3 1/2" | Needle Valve | Clamp On | 0000000 | 00000000 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Food and Beverage Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Features | Enclosure Rating | Mount Type | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1,750 | 1 | 3 5/8" | 316 Stainless Steel | 48" | 13/16" | 1.5 amp/0.8 amp | 60 | 60 1/16" | 61 | 3" | — | IP56 | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 350 | 1 | 10" | 316 Stainless Steel | 48" | 13/16" | 1.5 amp/0.8 amp | 60 | 60 1/16" | 64 | 3" | High-Flow Propeller | IP56 | Clamp On | Totally Enclosed Fan-Cooled (TEFC) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flange-Mount Air-Powered Mixers for Tanks

Propellers | Shaft | Air Connection | Flange | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Dia. | Material | Bolt Circle Dia. | No. of Holes | Mounting Hole Dia. | Overall Ht. | Wt., lb. | Includes | Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 15" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 6" | Aluminum | 5" | 6 | 11/32" | 20 3/4" | 20 | Needle Valve | Flange | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 27" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 6" | Aluminum | 5" | 6 | 11/32" | 32 3/4" | 25 | Needle Valve | Flange | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 300 to 1,750 | 2 | 6" | 316 Stainless Steel | 48" | 5/8" | 1/4 | NPT | Female | 59 ft³/min @ 80 psi | 6" | Aluminum | 5" | 6 | 11/32" | 55 3/4" | 26 | Needle Valve | Flange | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 27" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 34 7/16" | 34 | Needle Valve | Flange | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 48" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 55 7/16" | 38 | Needle Valve | Flange | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 300 to 1,750 | 1 | 8" | 316 Stainless Steel | 60" | 3/4" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 67 7/16" | 41 | Needle Valve | Flange | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 300 to 1,750 | 1 | 10" | 316 Stainless Steel | 48" | 1" | 1/2 | NPT | Female | 110 ft³/min @ 80 psi | 7" | Aluminum | 6" | 6 | 1/2" | 55 7/16" | 44 | Needle Valve | Flange | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Variable-Speed Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Features | Mount Type | Cord Lg., ft. | Motor Enclosure Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC Single Phase—3 Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 to 1,750 | 1 | 3 13/16" | 316 Stainless Steel | 36" | 5/8" | 3.5 amp | 60 | 51" | 50 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 90 to 1,750 | 1 | 3 13/16" | 316 Stainless Steel | 48" | 5/8" | 3.5 amp | 60 | 63" | 51 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/3 | 90 to 1,750 | 1 | 4 1/2" | 316 Stainless Steel | 48" | 5/8" | 4.5 amp | 60 | 63" | 45 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 90 to 1,750 | 1 | 5 3/16" | 316 Stainless Steel | 48" | 3/4" | 6 amp | 60 | 63" | 55 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 20 to 350 | 1 | 10" | 316 Stainless Steel | 36" | 3/4" | 3.5 amp | 60 | 53 5/8" | 63 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 20 to 350 | 1 | 10" | 316 Stainless Steel | 48" | 3/4" | 3.5 amp | 60 | 65 5/8" | 65 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 20 to 350 | 1 | 11 13/16" | 316 Stainless Steel | 60" | 3/4" | 6 amp | 60 | 77 5/8" | 64 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 20 to 350 | 2 | 8 13/16" | 316 Stainless Steel | 48" | 3/4" | 6 amp | 60 | 65 5/8" | 61 | 3" | Adjustment Dial, High-Flow Propeller | Clamp On | 7 1/2 | Totally Enclosed Nonventilated (TENV) | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hazardous Location Electric Mixers for Tanks

Propellers | Shaft | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Power, hp | Mixer Speed, rpm | No. of | Dia. | Material | Lg. | Dia. | Current | Freq., Hz | Overall Ht. | Wt., lb. | Max. Clamp Opening | Hazardous Location Rating | Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120/240V AC Single Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 350 | 2 | 11" | 316 Stainless Steel | 60" | 3/4" | 11 amp/5.5 amp | 60 | 81 1/2" | 84 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | Clamp On | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

240/460V AC Three Phase—Wire Leads | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thin Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1,725 | 2 | 5" | 316 Stainless Steel | 60" | 1" | 3.6 amp/1.8 amp | 60 | 84" | 78 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | Clamp On | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Thick Liquids | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 350 | 2 | 13" | 316 Stainless Steel | 60" | 1" | 4.4 amp/2.2 amp | 60 | 80 1/2" | 70 | 4" | NEC Class I Divisions 1, 2 Groups C, D NEC Class II Divisions 1, 2 Groups F, G | Clamp On | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rim-Mount Mixer Clamps

|  |  |

Style 1 | Style 2 | Style 3 |

|  | |

Style 4 | Style 5 |

Style | For Mixer Mfr. Part No. | For Use On | Each | ||

|---|---|---|---|---|---|

| 1 | Lightnin EV1P25, Lightnin EV1P33, Lightnin EV1P50, Lightnin EV5P25, Lightnin EV5P33, Lightnin EV5P75 | Drums, Intermediate Bulk Containers, Tanks | 00000000 | 0000000 | |

| 2 | Neptune B-1.0, Neptune B-2.0, Neptune B-3.0 | Drums, Intermediate Bulk Containers, Tanks | 00000000 | 000000 | |

| 3 | Neptune BC-5.4, Neptune BC-7.4 | Drums, Intermediate Bulk Containers, Tanks | 00000000 | 000000 | |

| 4 | Neptune JD-4.0, Neptune JD-5.1, Neptune JD-5.3, Neptune JG-3.0, Neptune JG-3.2, Neptune JG-4.0, Neptune JG-4.2, Neptune JG-6.1, Neptune JG-6.3 | Drums, Intermediate Bulk Containers, Tanks | 00000000 | 000000 | |

| 5 | Neptune L-1-CL | Drums, Intermediate Bulk Containers, Tanks | 0000000 | 000000 |

Tank Mixing Nozzles

Orifice Dia. | Pipe Size | Thread Type | Gender | Inlet Flow Rate @ Pressure | Tank Circulation Rate @ Pressure | Dia. | Lg. | Max. Pressure @ Temp. | Max. Temp., ° F | Material | Color | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.06" | 1/4 | NPT | Male | 0.7 gpm @ 50 psi | 4.4 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Orange | 0000000 | 000000 | |

| 0.08" | 1/4 | NPT | Male | 1.2 gpm @ 50 psi | 6 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Green | 0000000 | 00000 | |

| 0.1" | 1/4 | NPT | Male | 2 gpm @ 50 psi | 7.8 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Blue | 0000000 | 00000 | |

| 0.12" | 1/4 | NPT | Male | 2.9 gpm @ 50 psi | 10.7 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | White | 0000000 | 00000 | |

| 3/16" | 1/4 | NPT | Male | 7.8 gpm @ 50 psi | 36.8 gpm @ 50 psi | 1 1/4" | 3" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 5/16" | 3/8 | NPT | Male | 20 gpm @ 50 psi | 100 gpm @ 50 psi | 1 11/16" | 4 1/16" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 3/8" | 3/4 | NPT | Male | 30 gpm @ 50 psi | 150 gpm @ 50 psi | 3" | 6 3/8" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 9/16" | 1 1/2 | NPT | Male | 75 gpm @ 50 psi | 375 gpm @ 50 psi | 4 1/2" | 10" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 000000 |