Food Industry Round Metal Batch Cans

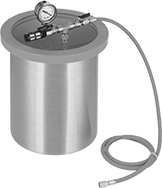

Vacuum Containers

Also known as vacuum degassing chambers, these remove trapped air from mixtures such as paint and mold resins. The fittings on the hose contain a gasket that allows you to connect the hose to flared fittings.

304 stainless steel containers have excellent corrosion resistance and are commonly used in laboratories.

Containers with a side-mount gauge allow you to see the material inside of them when looking from the top.

Glass lids resist corrosion. They’re primarily used to eliminate air bubbles in woodworking projects that use harsh chemicals, which would deteriorate plastic lids. Glass lids are less durable than acrylic lids.

Acrylic lids are more durable than glass lids. They’re commonly used to eliminate air bubbles in hard setting materials, such as silicone and polyurethane.

Replacement lids do not include hardware or seal.

Replacement manifold assemblies include a manifold, vacuum gauge, washer, O-ring, and hex nut.

Containers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gauge | Hose | Replacement Lids | |||||||||||||||||

| Cap. | Dia. | Ht. | Bottom ID | Vacuum Range, in. of Hg | Accuracy | Grad. Marks, in. of Hg | Lg. | Thread Size | Gender | For Connection Style | For Flared Angle | For Tube OD | Max. Temp., °F | Removes Particle Size Down To | Includes | Each | Each | ||

304 Stainless Steel with Top-Mount Gauge | |||||||||||||||||||

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 1/2 gal. | 8 1/4" | 9 1/4" | 7 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 0000000 | 0000000 | 0000000 |

304 Stainless Steel with Side-Mount Gauge | |||||||||||||||||||

Glass Lid with Silicone Rubber Seal | |||||||||||||||||||

| 1 1/2 gal. | 8 1/4" | 9 1/4" | 7 1/8" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 000000 | 0000000 | 00000 |

| Gauge Mounting Location | Each | |

| Side | 0000000 | 000000 |

| Removes Particle Size Down To | Each | |

| 50 microns | 0000000 | 00000 |

Heated Ultrasonic Cleaners

Heat cleaning solutions to increase their effectiveness. These ultrasonic cleaners use sound waves moving through the solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

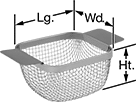

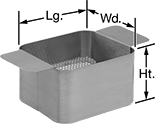

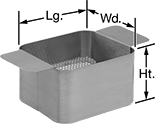

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

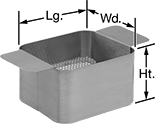

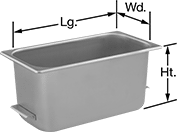

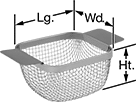

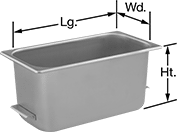

Cleaning pans act as a second cleaning tank when placed inside the tank of an ultrasonic cleaner. They have ledges that rest on top of the cleaner, leaving the bottom submerged in the tank’s solution. Ultrasonic waves from the tank transfer through the solid bottom of the basket to the solution inside.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

| 6 | 11 3/4" | 6" | 6" | 12 3/4" | 7" | 11" | 43 | 335 | 120V AC | 60 | Timer, Heater, Drain | ABS Plastic Cover | 0000000 | 000000000 |

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

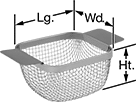

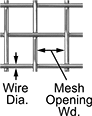

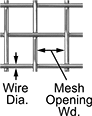

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 6 | 5 | 10 5/8" | 5 1/4" | 9" | 4" | 5" | 0.222" | 0.028" | 0000000 | 0000000 |

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

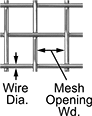

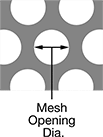

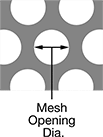

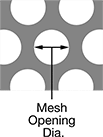

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 6 | 10 | 10 5/8" | 4 7/8" | 10 5/8" | 4 7/8" | 5" | 0.156" | 0000000 | 0000000 |

Top | Bottom | ||||||

|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Lg. | Wd. | Lg. | Wd. | Ht. | Each | |

304 Stainless Steel | |||||||

| 6 | 11 3/4" | 6" | 11" | 5 1/2" | 6" | 0000000 | 0000000 |

Programmable Heated Ultrasonic Cleaners

Precisely control the cleaning process by setting the temperature and time. Heating cleaning solutions and using the degas function to remove dissolved gases increases their effectiveness. These cleaners use sound waves moving through the solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

| 6 | 11 1/2" | 6" | 6" | 15 5/8" | 12 1/2" | 14 3/4" | 40 | 335 | 120V AC | 90 | Timer, Heater, Automatic Shut-Off, Degas Function, Sleep Mode, Drain | Cover | 0000000 | 000000000 |

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 6 | 5 | 10 5/8" | 5 1/4" | 9" | 4" | 5" | 0.222" | 0.028" | 0000000 | 0000000 |

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 6 | 10 | 10 5/8" | 4 7/8" | 10 5/8" | 4 7/8" | 5" | 0.156" | 0000000 | 0000000 |

Ultrasonic Cleaners

Sound waves move through the cleaning solution to create a scrubbing action that removes dirt from crevices and between tightly spaced parts.

Heavy duty baskets have solid sides with a perforated mesh bottom. They’re more durable than wire mesh baskets.

Cleaning pans act as a second cleaning tank when placed inside the tank of an ultrasonic cleaner. They have ledges that rest on top of the cleaner, leaving the bottom submerged in the tank’s solution. Ultrasonic waves from the tank transfer through the solid bottom of the basket to the solution inside.

Inside | O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., qt. | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Frequency, kHz | Wattage | Voltage | Max. Timer Duration, min. | Features | Includes | Each | |

Timed Cleaning | ||||||||||||||

| 6 | 11 3/4" | 6" | 6" | 12 3/4" | 7" | 11" | 43 | 135 | 120V AC | 60 | Timer, Drain | ABS Plastic Cover | 0000000 | 000000000 |

Top | Bottom | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Wd. | Wire Dia. | Each | |

304 Stainless Steel | ||||||||||

| 6 | 5 | 10 5/8" | 5 1/4" | 9" | 4" | 5" | 0.222" | 0.028" | 0000000 | 0000000 |

Top | Bottom | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Cap., lbs. | Lg. | Wd. | Lg. | Wd. | Ht. | Mesh Opening Dia. | Each | |

304 Stainless Steel | |||||||||

| 6 | 10 | 10 5/8" | 4 7/8" | 10 5/8" | 4 7/8" | 5" | 0.156" | 0000000 | 0000000 |

Top | Bottom | ||||||

|---|---|---|---|---|---|---|---|

| For Cleaner Cap., qt. | Lg. | Wd. | Lg. | Wd. | Ht. | Each | |

304 Stainless Steel | |||||||

| 6 | 11 3/4" | 6" | 11" | 5 1/2" | 6" | 0000000 | 0000000 |