Filter by

Material

Capacity

For Use With

Maximum Pressure

Maximum Temperature

Mounting Position

Minimum Temperature

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

Fuel Type

DFARS Specialty Metals

Mobility

Gender

Number of Ports

Opening Length

Opening Width

Pipe Size

Thread Type

Wall Thickness

Certification

Pressurized Liquid Dispensing Tanks

Tanks | Lids | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Opening | Gauge Port | Temp., ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cap., gal. | Max. Pressure @ 100° F, psi | Dia. | Ht. | Lg. | Wd. | Pipe Size | Thread Type | Gender | No. of | Min. | Max. | Certification | Cannot Be Sold To | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tanks Without Mounting Plate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 130 | 18" | 28" | 4 7/8" | 5 7/8" | 1/4 | NPT | Female | 4 | -20 | 200 | ASME BPVC.VIII.1 | Canada | 41665K74 | 000000000 | 4355T32 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 129 | 18" | 28" | 4 7/8" | 5 7/8" | 1/4 | NPT | Female | 4 | -20 | 300 | ASME BPVC.VIII.1 | Canada | 41665K73 | 00000000 | 4355T32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

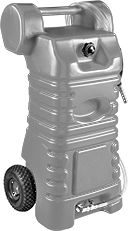

Mobile Fuel Dispensers

|

Style B |

Wheel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Fuel Type | Cap., gal. | Flow Rate, gpm | Lg. | Wd. | Ht. | Fill Opening Dia. | Nozzle OD | Hose Lg., ft. | Color | Finished Material | Material | Type | Shipping Std. | UN Shipping Std. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gravity Flow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Diesel Fuel | 25 | 2 | 17" | 22" | 43" | 2" | 3/4" | 8 | Yellow | Plastic | Rubber | Pneumatic | UN3H1W/Y1.2/110 | UN3H1W | 40855T92 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Gasoline | 25 | 2 | 17" | 22" | 43" | 2" | 3/4" | 8 | Red | Plastic | Rubber | Pneumatic | UN3H1W/Y1.2/110 | UN3H1W | 40855T91 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

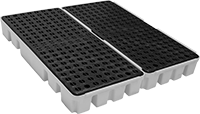

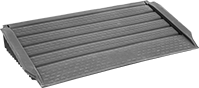

Plastic Spill-Control Pallets

Pallets | Ramps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Usable | Max. Fork | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | For No. of 55 gal. Drums | Cap., gal. | Wt. Cap., lb. | Lg. | Wd. | Ht. | Lg. | Wd. | Wt., lb. | Color | No. of Entry Points for Forklifts | Wd. | Ht. | With Drain | Space Saving Features | Each | Wt. Cap., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene—EPA Compliant 40 CFR 264.175 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 2 | 25 | 3,000 | 49" | 24" | 6 1/2" | 48" | 23" | 38 | Yellow | 2 | 6 31/32" | 1" | No | Stackable | 14195T27 | 0000000 | 1,000 | 14195T32 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||