About Air Preparation

More

Rectangular Plastic Tanks

Store large quantities of liquid in these flat-bottomed tanks. They have vented fill caps so air can flow in and out.

| Cap., gal. | Wd. | Dp. | Ht. | Thick. | Fill Opening Dia. | Grad. Marks | Color | Clarity | Max. Temp., °F | UV Protection | Includes | Each | |

Polyethylene Plastic | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 7 | 14" | 9" | 15" | 3/16" | 5" | 1 gal. | White | Semi-Clear | 120° | UV Resistant | Vented Fill Cap | 0000000 | 000000 |

| For Fill Opening Dia. | Features | Each | |

Polypropylene Plastic | |||

|---|---|---|---|

| 5" | Vent | 0000000 | 000000 |

Rectangular Plastic Batch Cans

These batch cans come with loose fitting dust covers to protect contents from dust and debris.

Bottom Inside | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polyethylene Plastic | ||||||||||||||

| 7 | 15 1/2" | 15 1/2" | 14" | 12" | 12" | 1/4" | White | Semi-Clear | Loose Fitting | 140° | Stackable | Seamless | 0000000 | 0000000 |

High-Temperature Rectangular Plastic Batch Cans

Bottom Inside | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, gal. | Wd. | Dp. | Ht. | Wd. | Dp. | Thick. | Color | Clarity | Lid Type | Max. Temp., °F | Space Saving Features | Features | Each | |

Polypropylene Plastic | ||||||||||||||

| 7 | 14 3/4" | 14 3/4" | 14 1/2" | 12" | 12" | 1/4" | White | Semi-Clear | Loose Fitting | 220° | Stackable | Seamless | 0000000 | 0000000 |

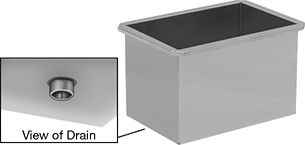

Rectangular Stainless Steel Batch Cans

Batch cans with drain have a drain centered on the bottom of the can.

Vacuum Containers

Also known as vacuum degassing chambers, these remove trapped air from mixtures such as paint and mold resins. The fittings on the hose contain a gasket that allows you to connect the hose to flared fittings.

Aluminum containers are lightweight, corrosion resistant, and good for general use.

Acrylic lids are more durable than glass lids. They’re commonly used to eliminate air bubbles in hard setting materials, such as silicone and polyurethane.

Replacement lids do not include hardware or seal.

Containers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gauge | Hose | Replacement Lids | |||||||||||||||||

| Cap. | Dia. | Ht. | Bottom ID | Vacuum Range, in. of Hg | Accuracy | Grad. Marks, in. of Hg | Lg. | Thread Size | Gender | For Connection Style | For Flared Angle | For Tube OD | Max. Temp., °F | Removes Particle Size Down To | Includes | Each | Each | ||

Aluminum with Top-Mount Gauge | |||||||||||||||||||

Acrylic Plastic Lid with Silicone Rubber Seal | |||||||||||||||||||

| 7 gal. | 16 3/4" | 9 3/4" | 16" | 0 to 30 | ±5% | 0.5 | 5 ft. | 7/16"-20 UNF | Female | Flared | 37°, 45° | 1/4" | 150° | 50 microns | 50 Micron Air Filter, Lid | 0000000 | 0000000 | 0000000 | 0000000 |

| Removes Particle Size Down To | Each | |

| 50 microns | 0000000 | 00000 |

ASME-Code Compressed Air Storage Tanks

These tanks have drain ports on the bottom to remove condensation. All other ports can be used as inlets or outlets in any configuration.

Tanks with mounting plate have a platform where you can secure motors, pumps, and other components.

Steel tanks are primed or powder coated for exterior corrosion resistance. Epoxy-lined steel tanks also resist interior corrosion that can result from moisture in your compressed air.

Stainless steel tanks are more corrosion resistant than steel tanks.

Safety regulations restrict sales to the listed jurisdictions/areas.

Note: Per ASME code, all tanks are water tested. Those made without a corrosion-resistant coating or material will have rust on the interior.

Ports | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Pressure, psi | Total No. of | Gender | Sizes | Lg. | Dia. | Ht. | Wall Thick. | Temp. Range, °F | Cannot Be Sold To | Each | |

Horizontal | ||||||||||||

Primed Steel | ||||||||||||

| 7 | 200 | 7 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (4 ea.) 1 NPT Port (1 ea.) 1/2 NPT Drain Port (1 ea.) | 17 3/4" | 12" | 14" | 1/8" | -20° to 400° | __ | 0000000 | 0000000 |

Epoxy-Lined Powder-Coated Steel | ||||||||||||

| 7 | 200 | 7 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (4 ea.) 1 1/2 NPT Port (1 ea.) 1/2 NPT Drain Port (1 ea.) | 17 3/4" | 12" | 14" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

316 Stainless Steel | ||||||||||||

| 7 | 200 | 7 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (4 ea.) 1 NPT Port (1 ea.) 1/2 NPT Drain Port (1 ea.) | 18 7/8" | 12" | 14" | 1/8" | -20° to 450° | Canada | 0000000 | 00000000 |

Horizontal with Mounting Plate | ||||||||||||

Primed Steel | ||||||||||||

| 7 | 200 | 5 | Female | 3/4 NPT Port (3 ea.) 1 NPT Port (1 ea.) 1/2 NPT Drain Port (1 ea.) | 17 3/4" | 12" | 15" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

Epoxy-Lined Powder-Coated Steel | ||||||||||||

| 7 | 200 | 5 | Female | 3/4 NPT Port (3 ea.) 1 NPT Port (1 ea.) 1/2 NPT Drain Port (1 ea.) | 17 3/4" | 12" | 15" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

Vertical | ||||||||||||

Powder-Coated Steel | ||||||||||||

| 7 | 200 | 5 | Female | 1/2 NPT Port (1 ea.) 3/4 NPT Port (2 ea.) 1 NPT Port (1 ea.) 3/4 NPT Drain Port (1 ea.) | __ | 10" | 25 3/8" | 1/8" | -20° to 400° | __ | 0000000 | 000000 |

Lightweight Compressed Air Storage Tanks

Tanks have drain ports on the bottom to remove condensation. All other ports can be used as inlets or outlets in any configuration.

They cannot be sold to New Jersey or Canada due to safety and pressure vessel regulations.

Ports | Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cap., gal. | Max. Pressure, psi | Total No. of | Gender | Sizes | Lg. | Dia. | Ht. | Wall Thick. | Temp. Range, °F | Cannot Be Sold To | Each | |

Horizontal | ||||||||||||

Fiberglass | ||||||||||||

| 7 | 150 | 4 | Female | 1/4 NPT Port (1 ea.) 3/4 NPT Port (2 ea.) 1/8 NPT Drain Port (1 ea.) | 29 3/8" | 9 1/4" | 12" | 1/8" | -20° to 150° | Canada, NJ | 000000 | 000000000 |