Filter by

For Use On

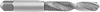

Thread Pitch

Flute Type

Thread Direction

Sold As

Finish

Maximum Tapping Depth

Overall Length

Drill Bit Size

Application

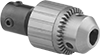

Length

Thread Length

DFARS Specialty Metals

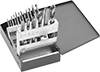

Tap Sizes Included

Fabricating and Machining

Fluid Handling

Fastening and Joining