Filter by

For Use On

Maximum Tapping Depth

Thread Length

Overall Length

Flute Type

Finish

Tap Sizes Included

Sold As

Thread Direction

Drill Bit Size

Drill Bit Decimal Size Equivalent

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Chip-Clearing Tap Sets

High-Speed Steel

Plug Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Thread Size | Thread Type | Flute Type | Container Type | Shank Type | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | M3, M4, M5, M6, M8, M10, M12 | Metric | Spiral Point | Plastic Case | Square | ISO 529 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gold Oxide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20 | UNF, UNC | Spiral Point | Metal Case | Square | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | 0-80, 1-64, 1-72, 2-56, 2-64, 3-48, 3-56, 4-40, 4-48, 5-40, 5-44, 6-32, 6-40, 8-32, 8-36, 10-24, 10-32, 12-24, 12-28 | UNF, UNC | Spiral Point | Metal Case | Square | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | M3, M4, M5, M6, M8, M10, M12 | Metric | Spiral Point | Plastic Case | Square | ISO 529 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Taps

Drill Bit | Plug Chamfer | Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0-80 | 9/32" | 1 5/8" | UNF | 2 | 3/64" | 0.0469" | Square | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2-56 | 7/16" | 1 3/4" | UNC | 2 | 51 Ga. | 0.067" | Square | 0000000 | 00000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 5/16" | 1 7/8" | UNC | 2 | 43 Ga. | 0.089" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 3/8" | 2" | UNC | 3 | 36 Ga. | 0.1065" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 3/8" | 2 1/8" | UNC | 4 | 29 Ga. | 0.136" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 1/2" | 2 3/8" | UNC | 4 | 25 Ga. | 0.1495" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1/2" | 2 3/8" | UNF | 4 | 21 Ga. | 0.159" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 2 1/2" | UNC | 4 | 7 Ga. | 0.201" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 5/8" | 2 1/2" | UNF | 4 | 3 Ga. | 0.213" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 2 23/32" | UNC | 4 | F | 0.257" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 2 15/16" | UNC | 4 | 5/16" | 0.3125" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 15/16" | 3 3/8" | UNC | 4 | 27/64" | 0.4219" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-12 | 1" | 3 19/32" | UNC | 4 | 31/64" | 0.4844" | Square | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 1/16" | 3 13/16" | UNC | 4 | 17/32" | 0.5313" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 7/32" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 1 7/32" | 4 1/4" | UNF | 4 | 11/16" | 0.6875" | Square | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 5/16" | 1 15/16" | Metric | 3 | 2.5 mm | 0.0984" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 3/8" | 2 1/8" | Metric | 4 | 3.3 mm | 0.1299" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 1/2" | 2 3/8" | Metric | 4 | 4.2 mm | 0.1654" | Square | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 5/8" | 2 1/2" | Metric | 4 | 5 mm | 0.1969" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 11/16" | 2 23/32" | Metric | 4 | 6.7 mm | 0.2638" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 1 1/4" | 2 31/32" | Metric | 4 | 8.5 mm | 0.3346" | Square | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Helical Insert Taps

Drill Bit | Plug Chamfer | Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Insert Size | Thread Lg. | Overall Lg. | For Insert Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1 1/16" | 2 7/16" | NPT | 4 | W | 0.386" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 1 1/2" | 3 1/8" | BSPP | 4 | 25/64" | 0.3906" | Square | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1 1/16" | 2 9/16" | NPT | 4 | 33/64" | 0.5156" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1 5/8" | 3 1/2" | BSPP | 4 | 17/32" | 0.5313" | Square | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 1 3/8" | 3 1/8" | NPT | 4 | 21/32" | 0.6563" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 1 7/8" | 4" | BSPP | 4 | 43/64" | 0.6719" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1 3/8" | 3 1/4" | NPT | 5 | 13/16" | 0.8125" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 2 1/4" | 4 7/8" | BSPP | 4 | 27/32" | 0.8738" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0-80 | 3/8" | 1 11/16" | UNF | 2 | 52 Ga. | 0.0635" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1-64 | 1/2" | 1 13/16" | UNC | 3 | 46 Ga. | 0.081" | Square | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1-64 | 9/16" | 1 7/8" | UNC | 3 | 46 Ga. | 0.0810" | Square | ——— | 0 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2-56 | 9/16" | 1 7/8" | UNC | 3 | 41 Ga. | 0.096" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3-48 | 5/8" | 1 15/16" | UNC | 3 | 7/64" | 0.1094" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3-56 | 5/8" | 1 15/16" | UNF | 3 | 36 Ga. | 0.1065" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 11/16" | 2" | UNC | 3 | 31 Ga. | 0.12" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-48 | 11/16" | 2" | UNF | 3 | 31 Ga. | 0.12" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-40 | 3/4" | 2 1/8" | UNC | 3 | 29 Ga. | 0.136" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 7/8" | 2 3/8" | UNC | 3 | 25 Ga. | 0.1495" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-40 | 3/4" | 2 1/8" | UNF | 3 | 25 Ga. | 0.1495" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 15/16" | 2 3/8" | UNC | 3 | 16 Ga. | 0.177" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 15/16" | 2 3/8" | UNF | 3 | 16 Ga. | 0.177" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 1" | 2 1/2" | UNC | 3 | 5 Ga. | 0.2055" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1" | 2 1/2" | UNF | 3 | 13/64" | 0.2031" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12-24 | 1 1/8" | 2 23/32" | UNC | 3 | 1 Ga. | 0.228" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 2 23/32" | UNC | 3 | H | 0.266" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/8" | 2 23/32" | UNF | 3 | 6.7 mm | 0.2637" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/4" | 2 15/16" | UNC | 4 | Q | 0.332" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/4" | 2 15/16" | UNF | 4 | 21/64" | 0.3281" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 21/32" | 3 3/8" | UNC | 4 | X | 0.397" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 7/16" | 3 5/32" | UNF | 4 | 25/64" | 0.3906" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 1 21/32" | 3 19/32" | UNC | 4 | 29/64" | 0.4531" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 1 21/32" | 3 3/8" | UNF | 4 | 29/64" | 0.4531" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 13/16" | 3 13/16" | UNC | 4 | 17/32" | 0.5313" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 21/32" | 3 19/32" | UNF | 4 | 33/64" | 0.5156" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-12 | 1 13/16" | 4 1/32" | UNC | 4 | 19/32" | 0.5938" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 13/16" | 3 13/16" | UNF | 4 | 37/64" | 0.5781" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 2" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 1 13/16" | 4 1/32" | UNF | 4 | 41/64" | 0.6406" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 7/32" | 4 11/16" | UNC | 4 | 25/32" | 0.7813" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 4 15/32" | UNF | 4 | 49/64" | 0.7656" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 2 1/2" | 5 1/16" | UNC | 4 | 29/32" | 0.9063" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 2 1/2" | 5 1/8" | UNF | 4 | 57/64" | 0.8906" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 9/16" | 5 3/4" | UNC | 4 | 1 1/32" | 1.0313" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-12 | 2 9/16" | 5 7/16" | UNF | 4 | 1 1/32" | 1.0313" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-14 | 2 9/16" | 5 7/16" | UNF | 4 | 1 1/32" | 1.0313" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8"-7 | 3" | 6 1/16" | UNC | 4 | 1 11/64" | 1.1719" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8"-12 | 2 9/16" | 5 3/4" | UNF | 4 | 1 5/32" | 1.1563" | Square | ——— | 0 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8"-12 | 2 9/16" | 5 3/4" | UNF | 6 | 1 5/32" | 1.1563" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 3" | 6 3/8" | UNC | 4 | 1 19/64" | 1.2969" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-8 | 3" | 6" | UN | 4 | 1 1/4" | 1.25" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 3" | 6 1/16" | UNF | 4 | 1 9/32" | 1.2813" | Square | ——— | 0 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-12 | 3" | 6 1/16" | UNF | 6 | 1 9/32" | 1.2813" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-6 | 3 3/16" | 6 11/16" | UNC | 6 | 1 27/64" | 1.4219" | Square | ——— | 0 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-6 | 3 3/16" | 7" | UNC | 6 | 1 35/64" | 1.5469" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-8 | 3" | 6 5/8" | UN | 6 | 1 1/2" | 1.5" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-12 | 3 3/16" | 6 11/16" | UNF | 6 | 1 17/32" | 1.5313" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4"-8 | 3 5/8" | 7 1/4" | UN | 6 | 1 3/4" | 1.75" | Square | 000000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4"-8 | 3 3/4" | 7 1/4" | UN | 6 | 1 3/4" | 1.75" | Square | ——— | 0 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 1/2" | 1 13/16" | Metric | 3 | 2.1 mm | 0.0827" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.2 | 9/16" | 1 7/8" | Metric | 3 | 2.3 mm | 0.0906" | Square | ——— | 0 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.2 | 9/16" | 1 7/8" | Metric | 3 | 2.35 mm | 0.0925" | Square | 000000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 | 5/8" | 1 15/16" | Metric | 3 | 37 Ga. | 0.104" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 11/16" | 2" | Metric | 3 | 3.2 mm | 0.1259" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 | 3/4" | 2 1/8" | Metric | 3 | 3.7 mm | 0.1456" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 7/8" | 2 3/8" | Metric | 3 | 19 Ga. | 0.166" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 1" | 2 1/2" | Metric | 3 | 5.3 mm | 0.2086" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 1 1/8" | 2 23/32" | Metric | 4 | 6.3 mm | 0.248" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M7 | 1 1/4" | 2 15/16" | Metric | 4 | 7.3 mm | 0.2874" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 1 1/4" | 2 15/16" | Metric | 4 | 8.3 mm | 0.3267" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 1 1/4" | 2 15/16" | Metric | 4 | 8.4 mm | 0.3307" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 1 7/16" | 3 3/16" | Metric | 4 | 13/32" | 0.4063" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 1 21/32" | 3 3/8" | Metric | 4 | 13/32" | 0.4063" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 1 21/32" | 3 3/8" | Metric | 4 | 10.5 mm | 0.4134" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 1 21/32" | 3 19/32" | Metric | 4 | 31/64" | 0.4844" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 1 21/32" | 3 19/32" | Metric | 4 | 12.5 mm | 0.4921" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 1 21/32" | 3 19/32" | Metric | 4 | 12.5 mm | 0.4921" | Square | 000000000 | 00000 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 | 1 13/16" | 3 13/16" | Metric | 4 | 37/64" | 0.5781" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 | 1 13/16" | 4 1/32" | Metric | 4 | 14.5 mm | 0.5709" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 2" | 4 1/4" | Metric | 4 | 21/32" | 0.6563" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 | 2" | 4 1/4" | Metric | 4 | 16.5 mm | 0.6496" | Square | 000000000 | 00000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 | 2 7/32" | 4 11/16" | Metric | 4 | 47/64" | 0.7344" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 2 7/32" | 4 11/16" | Metric | 4 | 13/16" | 0.8125" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 | 2 7/32" | 4 29/32" | Metric | 4 | 13/16" | 0.8125" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 | 1 1/2" | 4" | Metric | 4 | 31/32" | 0.9688" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M30 | 1 1/2" | 4" | Metric | 4 | 1 7/32" | 1.2188" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M36 | 3 1/4" | 6 5/8" | Metric | 6 | 1 15/32" | 1.4688" | Square | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Tap and Drill Bit Sets for Through Holes

No. of Pieces | Chamfer Type | Tap Sizes Included | Overall Lg. | Thread Type | No. of Flutes | Pitch Dia. Limit | Drill Bit Sizes Included | Drill Bit Material | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gold-Oxide High-Speed Steel Tap | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | Plug | 6-40 8-36 10-24 10-32 1/4"-28 5/16"-24 3/8"-24 7/16"-20 1/2"-20 | 2 1/16" 2 7/32" 2 15/32" 2 5/8" 2 7/8" 3 1/8" 3 5/32" 3 3/8" | UNF | 2, 3 | H2, H3 | 29/64" 25/64" 33 ga. 29 ga. 25 ga. 21 ga. 3 ga. I Q | Gold-Oxide High-Speed Steel | Metal Case | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | Plug | M2.5 × 0.45 mm M3 × 0.5 mm M3.5 × 0.6 mm M4 × 0.7 mm M5 × 0.8 mm M6 × 1.00 mm M8 × 1.25 mm M10 × 1.5 mm M12 × 1.75 mm | 1 13/16" 1 15/16" 2" 2 1/8" 2 3/8" 2 1/2" 2 23/32" 2 15/16" 3 3/8" | Metric | 2, 3 | D3, D4, D5, D6 | 2.05 mm 2.5 mm 2.9 mm 3.3 mm 4.2 mm 5 mm 6.7 mm 8.5 mm 10.2 mm | Gold-Oxide High-Speed Steel | Metal Case | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Mills

For Internal Threads (UNC, UNEF, UNF, UNJ, UNS)

|

For Min. Screw Size | Threads per In. | Thread Lg. | Overall Lg. | No. of Flutes | Shank Size | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Titanium Nitride (AlTiN)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 40 | 3/16" | 2 1/2" | 2 | 1/4" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 32 | 17/64" | 2 1/2" | 3 | 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 32 | 17/64" | 2 1/2" | 3 | 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 24 | 11/32" | 2 1/2" | 3 | 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 32 | 21/64" | 2 1/2" | 3 | 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 20 | 33/64" | 2 1/2" | 3 | 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 18 | 5/8" | 2 1/2" | 3 | 1/4" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 16 | 25/32" | 3" | 4 | 5/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 13 | 7/8" | 3" | 4 | 3/8" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Internal/External Threads (UNC, UNEF, UNF, UNS) and Internal Threads (UNJ)

|

|

For Min. Screw Size | Threads per In. | Overall Lg. | Shank Size | Neck Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Titanium Nitride (AlTiN)-Coated Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 | 56 to 80 | 1 1/2" | 1/8" | 0.034" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 48 to 80 | 2" | 3/16" | 0.045" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 32 to 56 | 2" | 3/16" | 0.049" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 32 to 56 | 2" | 3/16" | 0.07" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 28 to 48 | 2" | 3/16" | 0.075" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 24 to 48 | 2" | 3/16" | 0.08" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 24 to 48 | 2 1/2" | 1/4" | 0.104" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 16 to 48 | 2 1/2" | 1/4" | 0.153" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 18 to 48 | 3" | 3/8" | 0.192" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 12 to 48 | 3" | 3/8" | 0.24" | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand Thread Helical Insert Taps

Drill Bit | Plug Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Insert Size | Thread Lg. | Overall Lg. | For Insert Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1 1/8" | 2 23/32" | UNC | 4 | H | 0.266" | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1 1/8" | 2 23/32" | UNF | 4 | 6.7 mm | 0.2637" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/4" | 2 15/16" | UNC | 4 | Q | 0.332" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/4" | 2 15/16" | UNF | 4 | 21/64" | 0.3281" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 21/32" | 3 3/8" | UNC | 4 | X | 0.397" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 7/16" | 3 5/32" | UNF | 4 | 25/64" | 0.3906" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 13/16" | 3 13/16" | UNC | 4 | 17/32" | 0.5313" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 21/32" | 3 19/32" | UNF | 4 | 33/64" | 0.5156" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 13/16" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 1 13/16" | 4 1/32" | UNF | 4 | 41/64" | 0.6406" | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 7/32" | 4.667" | UNC | 4 | 25/32" | 0.7813" | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

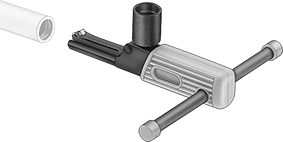

Internal Thread Repair Tools for Any Thread Pitch

Thread Repair Tools | Replacement Thread Repair Tool Pads | Replacement Thread Repair Tool Blades | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For ID | For Threads per Inch | For Thread Pitch | Overall Lg. | Blade Material | Handle Material | Each | Each | Each | |||||

| 5/16" to 7/16", 8 mm to 11 mm | Any | Any | 4 5/16" | Steel | Plastic | 0000000 | 0000000 | 0000000 | 00000 | 0000000 | 000000 | ||

| 1/2" to 5/8", 12 mm to 16 mm | Any | Any | 4 5/16" | Steel | Plastic | 0000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 | ||

| 11/16" to 13/16", 16 mm to 20 mm | Any | Any | 4 3/8" | Steel | Plastic | 0000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 | ||

| 7/8" to 1 1/4", 22 mm to 32 mm | Any | Any | 5 3/8" | Steel | Plastic | 0000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 | ||

Thread-Repairing File Sets

For Internal and External Threads

No. of Pieces | For Threads per In. | For Thread Pitch, mm | Overall Lg. | Material | Container Type | Each | ||

|---|---|---|---|---|---|---|---|---|

| 4 | 8, 9, 10, 11, 11 1/2, 12, 13, 14, 16, 18, 20, 24, 27, 28, 32 | 0.75, 1, 1.25, 1.5, 1.75, 2, 2.5, 3 | 9 1/4" | Steel | Plastic Pouch | 0000000 | 0000000 |

Fastener Thread-Repairing Files

Pipe and Conduit Thread-Repairing Files

For Internal and External Threads

|

For Threads per In. | Wd. | Thk. | Overall Lg. | Material | Each | ||

|---|---|---|---|---|---|---|---|

| 8, 10, 11 1/2, 14, 16, 18, 24, 27 | 3/8" | 3/8" | 9 1/4" | Steel | 0000000 | 000000 |