Filter by

Thread Size

For Use On

Thread Direction

Flute Type

Tap Sizes Included

Sold As

Material

Application

Die Sizes Included

Component

Finish

Shank Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

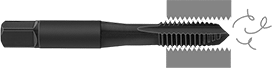

Taps

Taps | Taps Sold as Sets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Drill Bit | Taper Chamfer | Plug Chamfer | Bottoming Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | Each | Each | No. of Taps | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 000000 | 3 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | 3 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cobalt Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 7/32" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | ——— | 0 | 0000000 | 00000 | ——— | 0 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 7/32" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | ——— | 0 | 0000000 | 000000 | ——— | 0 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Aluminum Nitride (TiAlN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 7/32" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | ——— | 0 | 0000000 | 000000 | 0000000 | 000000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap Sets

High-Speed Steel—Single Thread Size Sets

|

Taper, Plug, and Bottoming Chamfer Set |

Taper Chamfer, Plug Chamfer, Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Thread Size | Thread Type | Container Type | No. of Flutes | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-10 | UNC | Plastic Case | 4 | Square | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-10 | UNC | Plastic Case | 4 | Square | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-10 | UNC | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel—Single Thread Size Sets

|

Taper, Plug, and Bottoming Chamfer Set |

Taper Chamfer, Plug Chamfer, Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Thread Size | Thread Type | Container Type | No. of Flutes | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-10 | UNC | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel—Multiple Thread Size Sets

Taper Chamfer, Plug Chamfer, Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Thread Size | Thread Type | Container Type | Shank Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | 3 each of sizes 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16, 7/8"-9, 7/8"-14, 1"-8, and 1"-12 | UNF, UNC | Plastic Case | Square | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap and Die Sets

No. of Pieces | Tap Sizes Included | Tap Chamfer Type | Die Shape | Die Sizes Included | Wd. | Container Type | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel Taps and Dies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Right-Hand Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 53 | 6-32, 8-32, 10-24, 10-32, 12-24, 1/8"-27, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16, 1/4"-18 | Plug, Taper | Hex | 6-32, 8-32, 10-24, 10-32, 12-24, 1/8"-27, 1/4"-18, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16 | 1", 1 7/16" | Plastic Case | Die Wrench (2), Screwdriver, Tap Wrench (3), Thread Gauge | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 65 | 4-40, 6-32, 8-32, 10-24, 10-32, 12-24, 1/8"-27, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16, 7/8"-9, 7/8"-14, 1"-8, 1"-14, 1/4"-18 | Plug, Taper | Hex | 4-40, 6-32, 8-32, 10-24, 10-32, 12-24, 1/8"-27, 1/4"-18, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16, 7/8"-14, 7/8"-9, 1"-8, 1"-14 | 5/8", 1", 1 7/16", 1 13/16" | Plastic Case | Die Wrench (4), Tap Wrench (4), Thread Gauge | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel Taps and Dies | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Right-Hand Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 58 | 6-32, 8-32, 10-24, 10-32, 12-24, 1/8"-27, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16, 1/4"-18 | Plug | Hex | 6-32, 8-32, 10-24, 10-32, 12-24, 1/8"-27, 1/4"-18, 1/4"-20, 1/4"-28, 5/16"-18, 5/16"-24, 3/8"-16, 3/8"-24, 7/16"-14, 7/16"-20, 1/2"-13, 1/2"-20, 9/16"-12, 9/16"-18, 5/8"-11, 5/8"-18, 3/4"-10, 3/4"-16 | 1", 1 7/16" | Plastic Case | Die Wrench (2), Extractor (5), Screwdriver, Tap Wrench (3), Thread Gauge | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap, Die, and Thread File Sets

No. of Pieces | Tap Sizes Included | Die Sizes Included | File Sizes Included | Container Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Right-Hand Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 48 | 1/2"-13, 1/2"-20, 1/4”-20, 1/4”-28, 3/8"-16, 3/8"-24, 5/16"-24, 5/16”-18, 7/16"-14, 7/16"-20, 9/16"-18, 9/16”-12, M6 × 1.00 mm, M8 × 1.25 mm, M10 × 1.00 mm, M10 × 1.25 mm, M10 × 1.50 mm, M11 × 1.50 mm, M12 × 1.25 mm, M12 × 1.50 mm, M12 × 1.75 mm, M14 × 1.50 mm | 1/2"-13, 1/2"-20, 1/4"-20, 1/4"-28, 3/8"-16, 3/8"-24, 5/16"-18, 5/16"-24, 5/8"-11, 5/8"-18, 7/16"-14, 7/16"-20, 9/16"-12, 9/16"-18, M6 × 1.00 mm, M8 × 1.25 mm, M10 × 1.00 mm, M10 × 1.25 mm, M10 × 1.50 mm, M11 × 1.50 mm, M12 × 1.25 mm, M12 × 1.50 mm, M12 × 1.75 mm, M14 × 1.50 mm | For 0.75 to 3 mm thread pitches, For 11 to 24 threads per inch | Plastic Case | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

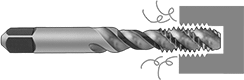

Chip-Clearing Taps

Drill Bit | Spiral-Point Flute for Through Holes | Spiral Flute for Blind Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | Chamfer Type | No. of Flutes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 15/64" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | — | — | ——— | 0 | Plug | 4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 15/64" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | — | — | ——— | 0 | Bottoming | 4 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 00000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 15/64" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | — | — | ——— | 0 | Plug | 4 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 15/64" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | — | — | ——— | 0 | Bottoming | 4 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Taps for Steel and Stainless Steel

Drill Bit | Spiral-Point Flute for Through Holes | Spiral Flute for Blind Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | Chamfer Type | No. of Flutes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Oxide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 7/32" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 0000000 | 000000 | Bottoming | 4 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Reach Taps

Drill Bit | Shank | Taper Chamfer | Plug Chamfer | Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Type | Dia. | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 6" | UNC | 4 | 21/32" | 0.6563" | Square | 0.59" | ——— | 0 | ——— | 0 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 3 1/4" | 9" | UNC | 4 | 21/32" | 0.6563" | Square | 0.616" | 00000000 | 0000000 | 0000000 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand Thread Taps

Tap Extractor Sets for Screw Thread Taps

No. of Pieces | For Three-Flute Tap Size | For Four-Flute Tap Size | Material | Container Type | For Number of Tap Flutes | Each | ||

|---|---|---|---|---|---|---|---|---|

| 11 | No. 5, No. 6, 1/8", M3, M3.5 | No. 8, No. 10, No. 12, No. 14, 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 15/32", 1/2", 9/16", 5/8", 11/16", 3/4", 13/16", 7/8", 15/16", 1", M4, M4.5, M5, M5.5, M6, M6.3, M7, M8, M9, M10, M11, M12, M12.5, M14, M16, M18, M19, M20, M22, M24, M25 | Steel | Plastic Case | 3, 4 | 00000000 | 0000000 | |

| 13 | No. 4, No. 5, No. 6, 1/8", M3, M3.5 | No. 8, No. 10, No. 12, No. 14, 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 15/32", 1/2", 9/16", 5/8", 11/16", 3/4", M4, M4.5, M5, M5.5, M6, M6.3, M7, M8, M9, M10, M11, M12, M12.5, M14, M16, M18, M19, M20 | Steel | Plastic Case | 3, 4 | 00000000 | 000000 | |

| 15 | No. 4, No. 5, No. 6, 1/8", M3, M3.5 | No. 8, No. 10, No. 12, No. 14, 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 15/32", 1/2", 9/16", 5/8", 11/16", 3/4", 13/16", 7/8", 15/16", 1", M2, M4, M4.5, M5, M5.5, M6, M6.3, M7, M8, M9, M10, M11, M12, M12.5, M14, M16, M18, M19, M20, M22, M24, M25 | Steel | Plastic Case | 3, 4 | 00000000 | 000000 |

Acme Thread Taps

Drill Bit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4 5/16" | 7 15/16" | Acme | 4 | 21/32" | 0.6563" | Square | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

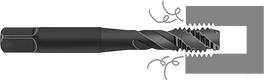

Oversized Chip-Clearing Taps

|

Spiral-Point Flute for Through Holes |

Drill Bit | Spiral-Point Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drill Taps

Straight Flute |

Thread | Drill Bit | Plug Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Lg. | Overall Lg. | Size | Decimal Size Equiv. | Point Angle | Flute Type | No. of Flutes | Thread Type | Pitch Dia. Limit | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 6" | 21/32" | 0.6563" | 110° | Straight | 4 | UNC | H3 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand Acme Thread Taps

Drill Bit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 4 5/16" | 7 15/16" | Acme | 4 | 21/32" | 0.6563" | Square | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand Thread Tap Sets

|

High-Speed Steel—Single Thread Size Sets

Taper Chamfer, Plug Chamfer, Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Thread Size | Thread Type | No. of Flutes | Shank Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-10 | UNC | 4 | Square | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Taps for Titanium

|

Spiral Flute for Through Holes |

Drill Bit | Spiral Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cobalt Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Oxide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 13/16" | 4 29/32" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Taps for Nickel

Drill Bit | Spiral Flute for Through Holes | Spiral Flute for Blind Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | Chamfer Type | No. of Flutes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cobalt Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Oxide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 00000000 | 0000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 19/32" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | — | — | ——— | 0 | Plug | 3 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Helical Insert Taps

Left-Hand Thread Helical Insert Taps

Drill Bit | Plug Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Insert Size | Thread Lg. | Overall Lg. | For Insert Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2 7/32" | 4.667" | UNC | 4 | 25/32" | 0.7813" | Square | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap Extractors for Screw Thread Taps

Helical Threaded Inserts with Installation Tools

Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Inserts Included | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pronged | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.750" | 25/32" | 0.781" | 5 | Drill Bit Installation Tool Through-Hole Tap | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.125" | 25/32" | 0.781" | 4 | Drill Bit Installation Tool Through-Hole Tap | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.500" | 25/32" | 0.781" | 5 | Drill Bit Installation Tool Through-Hole Tap | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand Thread Helical Threaded Inserts with Installation Tools

Thread Size | Installed Lg. | Drill Bit Size | For Max. Hole Dia. | No. of Inserts Included | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pronged | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.125" | 25/32" | 0.781" | 2 | Installation Tool Through-Hole Tap | 000000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||