Filter by

Thread Size

For Use On

Tap Sizes Included

Sold As

Thread Type

Flute Type

Maximum Tapping Depth

Overall Length

Container Type

Application

Finish

Thread Direction

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Tap and Drill Bit Sets

No. of Pieces | Chamfer Type | Tap Sizes Included | Overall Lg. | Thread Type | No. of Flutes | Pitch Dia. Limit | Drill Bit Sizes Included | Drill Bit Material | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Uncoated High-Speed Steel Tap | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | Plug | 1 each of sizes: M3 × 0.50 mm M3.5 × 0.60 mm M4 × 0.70 mm M5 × 0.80 mm M6 × 1.00 mm M8 × 1.25 mm M10 × 1.50 mm M12 × 1.75 mm | 1 15/16" 2" 2 1/8" 2 3/8" 2 1/2" 2 3/4" 2 15/16" 3 3/8" | Metric | 3, 4 | D3, D4, D5, D6 | 2.5 mm 2.9 mm 3.3 mm 4.2 mm 5.0 mm 6.75 mm 8.5 mm 10.25 mm | Black-Oxide High-Speed Steel | Plastic Pouch | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | Plug | 1 each of sizes: M2.5 × 0.45 mm M3 × 0.50 mm M3.5 × 0.60 mm M4 × 0.70 mm M5 × 0.80 mm M6 × 1.00 mm M8 × 1.25 mm M10 × 1.50 mm M12 × 1.75 mm | 1 3/4" 1 15/16" 2" 2 1/8" 2 3/8" 2 1/2" 2 23/32" 2 15/16" 3 3/8" | Metric | 3, 4 | D3, D4, D5, D6 | 2.05 mm 2.5 mm 2.9 mm 3.3 mm 4.2 mm 5.0 mm 6.7 mm 8.5 mm 10.2 mm | Uncoated High-Speed Steel | Metal Case | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap Sets

High-Speed Steel—Multiple Thread Size Sets

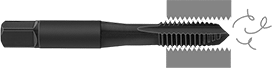

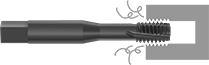

Plug Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Thread Size | Thread Type | Container Type | Shank Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 1 each of sizes M3 × 0.50 mm, M3.5 × 0.60 mm, M4 × 0.70 mm, M4.5 × 0.75 mm, M5 × 0.80 mm; M6 × 1.00 mm, M8 × 1.25 mm, M10 × 1.50 mm, M12 × 1.75 mm, and M16 × 2.00 mm | Metric | Metal Case | Square | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Tap and Drill Bit Sets for Through Holes

No. of Pieces | Chamfer Type | Tap Sizes Included | Overall Lg. | Thread Type | No. of Flutes | Pitch Dia. Limit | Drill Bit Sizes Included | Drill Bit Material | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gold-Oxide High-Speed Steel Tap | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | Plug | M2.5 × 0.45 mm M3 × 0.5 mm M3.5 × 0.6 mm M4 × 0.7 mm M5 × 0.8 mm M6 × 1.00 mm M8 × 1.25 mm M10 × 1.5 mm M12 × 1.75 mm | 1 13/16" 1 15/16" 2" 2 1/8" 2 3/8" 2 1/2" 2 23/32" 2 15/16" 3 3/8" | Metric | 2, 3 | D3, D4, D5, D6 | 2.05 mm 2.5 mm 2.9 mm 3.3 mm 4.2 mm 5 mm 6.7 mm 8.5 mm 10.2 mm | Gold-Oxide High-Speed Steel | Metal Case | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Taps

Taps | Taps Sold as Sets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Drill Bit | Taper Chamfer | Plug Chamfer | Bottoming Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size, mm | Decimal Size Equiv. | Shank Type | Each | Each | Each | No. of Taps | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 3 | 2.9 | 0.1142" | Square | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | 3 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 3 | 2.9 | 0.1142" | Square | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drill Out Tap Extractor Sets for Screw Thread Taps

No. of Pieces | Includes | For Tap Size | Overall Lg. | OD | Material | Container Type | Each | ||

|---|---|---|---|---|---|---|---|---|---|

| 7 | Four Tap Extractors, Pin Vise, Two Picks | No. 4, No. 5, No. 6, No. 8, No. 10, No. 12, 1/4", 5/16", 3/8", 7/16", 1/2", M3, M3.5, M4, M5, M6, M7, M8, M10, M12 | 1 1/4" 1 1/2" 2" 2 1/2" | 1/8" 5/64" 3/16" 1/4" | Carbide | Plastic Case | 0000000 | 0000000 |

Chip-Clearing Taps

|

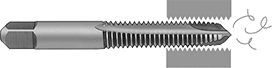

Spiral-Point Flute for Through Holes |

Drill Bit | Spiral-Point Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size, mm | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 2.9 | 0.1142" | Square | Plug | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 2.9 | 0.1142" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 2.9 | 0.1142" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap Extractor Sets for Screw Thread Taps

No. of Pieces | For Three-Flute Tap Size | For Four-Flute Tap Size | Material | Container Type | For Number of Tap Flutes | Each | ||

|---|---|---|---|---|---|---|---|---|

| 11 | No. 5, No. 6, 1/8", M3, M3.5 | No. 8, No. 10, No. 12, No. 14, 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 15/32", 1/2", 9/16", 5/8", 11/16", 3/4", 13/16", 7/8", 15/16", 1", M4, M4.5, M5, M5.5, M6, M6.3, M7, M8, M9, M10, M11, M12, M12.5, M14, M16, M18, M19, M20, M22, M24, M25 | Steel | Plastic Case | 3, 4 | 00000000 | 0000000 | |

| 13 | No. 4, No. 5, No. 6, 1/8", M3, M3.5 | No. 8, No. 10, No. 12, No. 14, 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 15/32", 1/2", 9/16", 5/8", 11/16", 3/4", M4, M4.5, M5, M5.5, M6, M6.3, M7, M8, M9, M10, M11, M12, M12.5, M14, M16, M18, M19, M20 | Steel | Plastic Case | 3, 4 | 00000000 | 000000 | |

| 15 | No. 4, No. 5, No. 6, 1/8", M3, M3.5 | No. 8, No. 10, No. 12, No. 14, 3/16", 7/32", 1/4", 9/32", 5/16", 11/32", 3/8", 7/16", 15/32", 1/2", 9/16", 5/8", 11/16", 3/4", 13/16", 7/8", 15/16", 1", M2, M4, M4.5, M5, M5.5, M6, M6.3, M7, M8, M9, M10, M11, M12, M12.5, M14, M16, M18, M19, M20, M22, M24, M25 | Steel | Plastic Case | 3, 4 | 00000000 | 000000 |

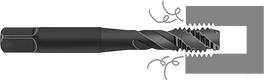

Chip-Clearing Taps for Steel and Stainless Steel

Chip-Clearing Taps for Aluminum, Brass, and Bronze

|

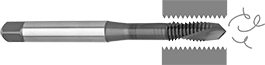

Spiral Flute for Through Holes |

Drill Bit | Spiral Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size, mm | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cobalt Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Nitride (TiN) Coated/Chromium Carbide (CrC) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/32" | 2 13/64" | Metric | 2.9 | 0.1142" | Square | Plug | 2 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drill Out Tap Extractors for Screw Thread Taps

For Tap Size | OD | Overall Lg. | Material | Each | ||

|---|---|---|---|---|---|---|

| No. 4, No. 5, No. 6, M3, M3.5 | 5/64" | 1 1/4" | Carbide | 0000000 | 000000 |

Long-Reach Chip-Clearing Taps

Drill Bit | Shank | Spiral-Point Flute for Through Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Type | Dia. | Chamfer Type | No. of Flutes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 6" | Metric | 32 Ga. | 0.116" | Square | 0.141" | Plug | 2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Reach Taps

Tap Extractors for Screw Thread Taps

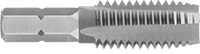

Hex-Bit Taps

|

Drill Bit | Plug Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size, mm | Decimal Size Equiv. | Shank Type | Hex Shank Size | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 3/8" | 1 5/16" | Metric | 3 | 2.9 | 0.1142" | Hex | 1/4" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Taps for Nickel

Oversized Chip-Clearing Taps

|

Spiral-Point Flute for Through Holes |

Drill Bit | Spiral-Point Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size, mm | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 2.9 | 0.1142" | Square | Plug | 2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oversized Taps

Drill Bit | Plug Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size, mm | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Uncoated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 3 | 2.9 | 0.114" | Square | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||