How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Compression Fittings for Plastic Tubing—Chemicals

- For Use With: PFA Plastic: Hydrochloric Acid, Sulfuric Acid

PTFE Plastic: Alcohol, Ammonia, Benzoic Acid, Bleach, Bromine, Coolant, Fluoboric Acid, Hydrochloric Acid, Hydrofluoric Acid, Nitric Acid, Organic Solvents, Sodium Carbonate, Sulfuric Acid - Temperature Range: PFA Plastic: 0° to 350° F

PTFE Plastic: -40° to 185° F - Tubing: PFA Plastic: Use with hard (Durometer 50D-65D) PFA or PTFE plastic

PTFE Plastic: Use with hard (Durometer 60D) PFA or PTFE plastic

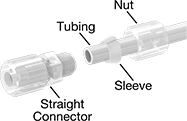

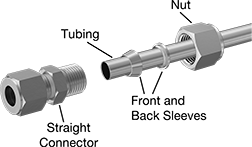

A sleeve (ferrule) compresses the tubing as you tighten the nut, creating a strong seal. The nut and sleeve are included. Fittings are also known as flareless fittings. Fittings that include a gripper sleeve on the tubing create an even tighter seal.

PTFE fittings are highly resistant to most acids, alcohols, detergents, and solvents. They’re made by machining. Their nut is made of PVDF, which is resistant to halogens such as chlorine and bromine, strong acids such as hydrofluoric and nitric acids, and organic solvents.

Ultra-Corrosion-Resistant Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Acetic Acid, Air, Bleach, Cutting Oil, Diesel Fuel, Formic Acid, Fuel Oil, Gasoline, Hydraulic Fluid, Iron Chlorides, Mineral Oil, Salt Water, Steam, Water

- Temperature Range: 0° to 1000° F

- Tubing: Use with seamless soft C276 nickel

- Specifications Met: ASME B31.3

With the best corrosion resistance of any metal tube fittings we offer, these C276 nickel Hastelloy fittings stand up to aggressive chemicals and resist pitting and cracking from stress. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They include a nut with two sleeves (ferrules). The sleeves bite into tubing as you tighten the nut, creating a strong, leak-resistant seal. Fittings are compatible with Swagelok®, Let-Lok, and A-Lok fittings.