How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

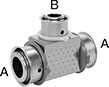

Low-Pressure Brass and Bronze Threaded Pipe Fittings

Use these fittings in low-pressure flow applications. They have good corrosion resistance.

- For Use With:

NPT: Air, Drinking Water, Natural Gas, Oil

BSPT: Air, Natural Gas, Oil, Steam, Water - Pressure Class: 125

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.15, NSF/ANSI 61

BSPT: ASME B16.15, ASME BS21, ASTM B584 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges:

NPT: Use Class 150 brass

BSPT: Use Class 150 bronze

| Pipe Size | Max. Pressure | Maximum Steam Pressure | Material | Each | |

BSPT Female | |||||

|---|---|---|---|---|---|

| 1/8 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 000000 |

| 1/4 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 3/8 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 1/2 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 3/4 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 1 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 1 1/4 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 1 1/2 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 00000 |

| 2 | 200 psi @ 72° F | 125 psi @ 400° F | Bronze | 00000000 | 000000 |

Bronze Unthreaded Pipe Fittings

Snap a brazing ring (sold separately) into these fittings and braze them to unthreaded pipe for a strong, leak-resistant connection. Fittings are also known as Silbraze fittings. They are bronze, which is compatible with brass and has good corrosion resistance.

- For Use With: Air, Oil, Steam, Water, Natural Gas

- Specifications Met: MIL-F-1183

- Pipe Nipples and Pipe: Use Schedule 40 brass

Fittings | Brazing Rings | |||||

|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | Each | ||

| 1/2 | 200 psi @ 72° F | 200 psi @ 425° F | 0000000 | 000000 | 0000000 | 00000 |

| 3/4 | 200 psi @ 72° F | 200 psi @ 425° F | 0000000 | 00000 | 0000000 | 0000 |

| 1 | 200 psi @ 72° F | 200 psi @ 425° F | 0000000 | 00000 | 0000000 | 0000 |

| 1 1/2 | 200 psi @ 72° F | 200 psi @ 425° F | 0000000 | 000000 | 0000000 | 0000 |

| 2 | 200 psi @ 72° F | 200 psi @ 425° F | 0000000 | 000000 | 0000000 | 0000 |

Press-Connect Fittings for Drinking Water

- Maximum Pressure: 160 psi @ 72° F

- Temperature Range: -30° to 180° F

- Tubing: Use with hard polyethylene plastic or copper

- Specifications Met: IAPMO Listed, NSF/ANSI 61

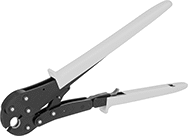

Connect drinking water lines with ease—these one-piece fittings have a built-in sleeve that crimps onto tubing for a leak-tight connection that doesn’t require heat or soldering. Each fitting has a viewing hole to prevent installation errors and ensure it’s fully inserted before installing them. Press them onto polyethylene tubing, also known as Viega PEX tubing, using a crimping tool (sold separately). Choose a crimping tool with a grip color that’s the same as your fitting’s ring color. They meet NSF/ANSI 61 for drinking water systems.

Fittings are IAPMO (International Association for Plumbing and Mechanical Officials) certified to comply with product performance standards. They also comply with the UPC (Uniform Plumbing Code) for installation and repair of plumbing systems.

Bronze fittings are strong and resist corrosion.

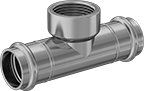

Press-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Maximum Pressure: Fittings compatible with Viega ProPress or Viega ProPress XL-C: 200 psi @ 72° F

Fittings compatible with Viega Pex or Viega PureFlow Press: 100 psi @ 72° F - Temperature Range: 0° to 250° F

- Tubing: Fittings compatible with Viega ProPress or Viega ProPress XL-C: Use with K, M, L copper

Fittings compatible with Viega Pex or Viega PureFlow Press: Use with hard polyethylene plastic - Specifications Met: See table

Crimp these fittings to copper tubing with a crimping tool (sold separately). An O-ring on the inside of the fitting creates a leak-tight connection that doesn’t require heat or soldering. They are comparable to Viega ProPress fittings. Fittings have good corrosion resistance. They meet NSF/ANSI safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

Inline tees are also known as branch tees. Use inline tee adapters to add lines or components, such as gauges, without additional fittings.

| Copper Tube Size | For Tube OD | Pipe Size | Material | Compatible With | Specifications Met | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 5/8" | 1/2 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 000000 |

| 3/4 | 7/8" | 1/4 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 3/4 | 7/8" | 1/2 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 3/4 | 7/8" | 3/4 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 1 | 1 1/8" | 1/2 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 1 | 1 1/8" | 3/4 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 1 1/4 | 1 3/8" | 1/2 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 1 1/4 | 1 3/8" | 3/4 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 1 1/2 | 1 5/8" | 1/2 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 1 1/2 | 1 5/8" | 3/4 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 2 | 2 1/8" | 1/2 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| 2 | 2 1/8" | 3/4 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

Right-angle tees are also known as run tees. Use right-angle tee adapters to add lines or components, such as gauges, without additional fittings.

| Copper Tube Size | For Tube OD | Pipe Size | Material | Compatible With | Specifications Met | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 5/8" | 1/8 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 000000 |

| 3/4 | 7/8" | 1/8 | Bronze | Viega ProPress | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, FM Approved, NSF/ANSI 61 | 00000000 | 00000 |

| For Copper Tube Size | For Tube OD | O-Ring Material | Compatible With | Each | |

| 1/2 | 5/8" | EPDM Rubber | Viega ProPress | 0000000 | 00000 |

| 3/4 | 7/8" | EPDM Rubber | Viega ProPress | 0000000 | 0000 |

| 1 | 1 1/8" | EPDM Rubber | Viega ProPress | 0000000 | 0000 |

| 1 1/4 | 1 3/8" | EPDM Rubber | Viega ProPress | 00000000 | 0000 |

| 1 1/2 | 1 5/8" | EPDM Rubber | Viega ProPress | 00000000 | 0000 |

| 2 | 2 1/8" | EPDM Rubber | Viega ProPress | 00000000 | 0000 |

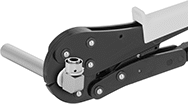

Jaws for copper tube sizes ½ to 2 fit directly into the included crimping tool.

Battery | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Copper Tube Size | For Tube OD | Voltage | No. Included | Cap., amp-hrs. | Battery Charger Included | Battery Charging Time, min. | Compatible With | Specifications Met | Each | |

| 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | 5/8", 7/8", 1 1/8", 1 3/8", 1 5/8", 2 1/8" | 18V DC | 2 | 3 | Yes | 39 | Viega ProPress | EMC 2011/65/EU, EMC 2014/30/EU, IEC 62841-1, UL 62841-1 | 00000000 | 000000000 |