Filter by

Thread Size

For Use With

Material

Height

Thickness

Export Control Classification Number (ECCN)

Length

Color

DFARS Specialty Metals

Maximum Temperature

Specifications Met

Hardness

Hardness Rating

Performance

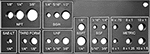

Pipe Thread Identifiers

Check external NPT thread size and taper.

| For Thread Type | For Thread Location | For Pipe Size | Wd. | Ht. | Thick. | Color | Each | |

Aluminum | ||||||||

|---|---|---|---|---|---|---|---|---|

| NPT | External | 1/16, 1/8, 1/4, 3/8, 1/2 | 2" | 3" | 1/4" | Blue | 000000 | 000000 |

Grease Fitting Size Identifiers

Take the guesswork out of determining the thread type and size of a grease fitting. Screw the shank of a grease fitting into the labeled holes of these identifiers until you find the one that fits.

| For Thread Type | For Thread Location | For Thread Size | For Screw Size | For Pipe Size | Wd. | Ht. | Thick. | Each | |

Inch, Metric | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||

| NPT, SAE-LT, BSW, UNF, BSPT, BSF, Metric | External | 3/16"-32, 1/4"-20, 1/4"-26, 1/4"-28, 5/16"-18, 5/16"-22, 5/16"-24, 3/8"-20, 3/8"-24, 1/2"-12, M6 × 0.75 mm, M6 × 1 mm, M8 × 1 mm, M8 × 1.25 mm, M10 × 1 mm, M10 × 1.5 mm | 1/8", 1/4" | 1/8, 1/4, 3/8 | 8 1/2" | 3" | 1/4" | 0000000 | 000000 |

Easy-to-Form 1100 Aluminum Wire

Spool

Coil

1-ft. Length

- Yield Strength: 3,500 psi

- Hardness: Not Rated (Soft)

- Temper: O

- Fabrication: Cold Drawn

- Specifications Met: ASTM B211

This wire has a soft temper and will stay in place when bent. Use it as tie wire and for bundling. Because 1100 aluminum is 99% pure, it offers superior formability, corrosion resistance, and electrical conductivity.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Container | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Lg., ft. | Heat Treatment | Max. Temperature, °F | Tensile Strength, psi | Net Weight, lbs. | Type | Each | |

| 0.013" | -0.001" to 0.001" | 1,735 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 000000 |

| 0.013" | -0.001" to 0.001" | 6,940 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.013" | -0.001" to 0.001" | 34,700 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.016" | -0.001" to 0.001" | 1,085 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.016" | -0.001" to 0.001" | 4,355 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.016" | -0.001" to 0.001" | 21,790 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.020" | -0.001" to 0.001" | 680 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.020" | -0.001" to 0.001" | 2,725 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.020" | -0.001" to 0.001" | 13,635 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.025" | -0.001" to 0.001" | 430 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.025" | -0.001" to 0.001" | 1,720 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.025" | -0.001" to 0.001" | 8,605 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.032" | -0.001" to 0.001" | 265 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.032" | -0.001" to 0.001" | 1,075 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.032" | -0.001" to 0.001" | 5,380 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.040" | -0.002" to 0.002" | 165 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.040" | -0.002" to 0.002" | 675 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.040" | -0.002" to 0.002" | 3,390 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.051" | -0.002" to 0.002" | 105 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.051" | -0.002" to 0.002" | 425 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.051" | -0.002" to 0.002" | 2,130 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.064" | -0.002" to 0.002" | 67 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.064" | -0.002" to 0.002" | 265 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.064" | -0.002" to 0.002" | 1,340 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 000000 |

| 0.080" | -0.002" to 0.002" | 2,025 | Annealed (Softened) | 200° | 11,000 | 12 | Coil | 0000000 | 000000 |

| 0.081" | -0.002" to 0.002" | 42 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.081" | -0.002" to 0.002" | 165 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.081" | -0.002" to 0.002" | 840 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 00000 |

| 0.114" | -0.002" to 0.002" | 21 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 0000 |

| 0.114" | -0.002" to 0.002" | 84 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.114" | -0.002" to 0.002" | 420 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 00000 |

| 0.114" | -0.002" to 0.002" | 1,010 | Annealed (Softened) | 200° | 11,000 | 12 | Coil | 0000000 | 000000 |

| 0.125" | -0.002" to 0.002" | 830 | Annealed (Softened) | 200° | 11,000 | 12 | Coil | 0000000 | 000000 |

| 0.126" | -0.002" to 0.002" | 17 | Annealed (Softened) | 200° | 11,000 | 1/4 | Spool | 0000000 | 00000 |

| 0.126" | -0.002" to 0.002" | 69 | Annealed (Softened) | 200° | 11,000 | 1 | Spool | 0000000 | 00000 |

| 0.126" | -0.002" to 0.002" | 330 | Annealed (Softened) | 200° | 11,000 | 5 | Spool | 0000000 | 00000 |

1 ft. Lg. | |||||||

|---|---|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Heat Treatment | Max. Temperature, °F | Tensile Strength, psi | Pkg. Qty. | Pkg. | |

| 0.013" | -0.001" to 0.001" | Annealed (Softened) | 200° | 11,000 | 25 | 0000000 | 00000 |

| 0.016" | -0.001" to 0.001" | Annealed (Softened) | 200° | 11,000 | 25 | 0000000 | 0000 |

| 0.020" | -0.001" to 0.001" | Annealed (Softened) | 200° | 11,000 | 25 | 0000000 | 00000 |

| 0.025" | -0.001" to 0.001" | Annealed (Softened) | 200° | 11,000 | 25 | 0000000 | 00000 |

| 0.032" | -0.001" to 0.001" | Annealed (Softened) | 200° | 11,000 | 10 | 0000000 | 0000 |

| 0.040" | -0.002" to 0.002" | Annealed (Softened) | 200° | 11,000 | 10 | 0000000 | 0000 |

| 0.051" | -0.002" to 0.002" | Annealed (Softened) | 200° | 11,000 | 10 | 0000000 | 0000 |

| 0.064" | -0.002" to 0.002" | Annealed (Softened) | 200° | 11,000 | 10 | 0000000 | 0000 |

| 0.081" | -0.002" to 0.002" | Annealed (Softened) | 200° | 11,000 | 10 | 0000000 | 00000 |

Thread Gauges for Lug Nuts

Identify the most common bolt thread sizes.

| For Thread Size | For Thread Location | Material | Each | |

| 7/16"-20 1/2"-20 9/16"-18 M12 × 1.25 mm M12 × 1.5 mm M12 × 1.75 mm M14 × 1.25 mm M14 × 1.5 mm M14 × 2 mm M16 × 1.5 mm | External, Internal | Aluminum | 00000000 | 000000 |