Filter by

Thread Size

System of Measurement

Fastener Strength Grade/Class

Material

Threading

Thread Spacing

Thread Direction

Tensile Strength

Thread Fit

REACH

RoHS

Finish

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Threaded Rods

Anchor, connect, or hang components in a wide variety of applications, from mounting I-beams to suspending light fixtures.

High-Strength Steel

|

With a tensile strength of 150,000 psi, these rods are strong enough to stabilize steel frameworks and structural supports, such as I-beams. They are about 25% stronger than medium-strength steel rods. To avoid stripped threads during installation, make sure your nuts are also high-strength steel.

Steel—Best for dry environments since moisture will cause these rods to rust.

Medium-Strength Steel

|

With tensile strengths from 110,000 psi to 125,000 psi, these rods are strong enough for most industrial applications, such as anchoring machinery and connecting pipe flanges. They are about twice as strong as low-strength steel rods. To avoid stripped threads during installation, make sure your nuts are also medium-strength steel.

Zinc-Plated Steel—The most common choice for areas with occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these rods to rust.

Lg. | Tensile Strength, psi | Fastener Strength Grade/Class | Hardness | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M42 × 4.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 m | 110,000 | ISO Class 8.8 | Rockwell C20 | DIN 976 | 99067A143 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M42 × 4.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300 mm | 110,000 | ISO Class 8.8 | Rockwell C20 | DIN 976 | 99055A344 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 m | 125,000 | ASTM Grade B7 | Rockwell C35 | ASTM A193, DIN 976 | 93325A370 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 m | 110,000 | ISO Class 8.8 | Rockwell C20 | DIN 976 | 99055A345 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 m | 125,000 | ASTM Grade B7 | Rockwell C35 | ASTM A193, DIN 976 | 93325A456 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Strength Steel

|

With a tensile strength of 50,000 psi or 60,000 psi, these rods are often used to suspend light fixtures, cable trays, and conduit from ceilings. They're about half the strength of medium-strength steel rods. To avoid stripped threads during installation, make sure your nuts are also low-strength steel.

Zinc-Plated Steel—The most common choice for areas with occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these rods to rust.

Stainless Steel

|

More corrosion resistant than steel rods and comparable in strength to low-strength steel.

18-8 Stainless Steel—The choice for wet and outdoor environments, these rods resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

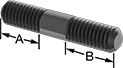

Threaded on Both Ends Setup Studs

Known as setup studs, these studs withstand sideways forces better than fully threaded studs because they have a strong unthreaded middle. The unthreaded middle also makes more contact with unthreaded holes, creating better alignment than a fully threaded stud.