Filter by

Flute Type

Thread Direction

Thread Pitch

Sold As

Material

Maximum Tapping Depth

Shank Type

Overall Length

Thread Length

Number of Pieces

Tap Sizes Included

For Threading

DFARS Specialty Metals

Export Control Classification Number (ECCN)

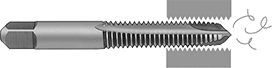

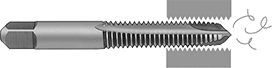

Taps

Cut threads into holes so screws, bolts, and rods fit snugly. Our basic taps have straight flutes that are good for most jobs.

High-Speed Steel—The most versatile taps resist heat and wear to stay sharp. They’re good for most metals and plastic.

Titanium Carbon Nitride (TiCN) Coated—Resist heat, chipping, and wear for three times the life of uncoated taps.

Taper Chamfer—Good for both starting holes and threading through holes. These taps have the longest taper to gradually engage with the material, reducing the force needed to turn them. They can't reach the bottom of blind holes, however, so you will likely need to finish with a bottoming-chamfer tap.

Plug Chamfer—Our go-to chamfer type, these thread both through holes and blind holes. The tapered section is shorter than a taper chamfer and longer than bottoming chamfer. As a result, they're easier to turn than bottoming taps but require more force than taper taps.

Bottoming Chamfer—Cut all the way to the bottom of blind holes with taps that have the shortest taper. Since these require the most force to turn, they’re often used to finish holes started by taper- or plug-chamfer taps.

Number of Flutes—Taps with fewer flutes have more space to capture chips, so you won’t have to clear them as often. However, they can be more difficult to keep straight in the hole.

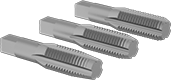

Taps Sold as Sets—Include one tap of each chamfer type.

Taps | Taps Sold as Sets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Drill Bit | Taper Chamfer | Plug Chamfer | Bottoming Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | Each | Each | No. of Taps | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0-80 | 5/16" | 1 5/8" | UNF | 2 | 3/64" | 0.0469" | Square | 000000000 | 000000 | 00000000 | 000000 | 000000000 | 000000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2-56 | 7/16" | 1 3/4" | UNC | 3 | 51 Ga. | 0.067" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 9/16" | 1 7/8" | UNC | 3 | 43 Ga. | 0.089" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-40 | 5/8" | 1 15/16" | UNC | 3 | 38 Ga. | 0.1015" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 11/16" | 2" | UNC | 3 | 36 Ga. | 0.1065" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-40 | 11/16" | 2" | UNF | 3 | 33 Ga. | 0.113" | Square | 000000000 | 00000 | 000000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 3/4" | 2 1/8" | UNC | 4 | 29 Ga. | 0.136" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 7/8" | 2 3/8" | UNC | 4 | 25 Ga. | 0.1495" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 7/8" | 2 3/8" | UNF | 4 | 21 Ga. | 0.159" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12-24 | 15/16" | 2 3/8" | UNC | 4 | 16 Ga. | 0.177" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 2 1/2" | UNC | 4 | 7 Ga. | 0.201" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1" | 2 1/2" | UNF | 4 | 3 Ga. | 0.213" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/8" | 2 23/32" | UNC | 4 | F | 0.257" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/8" | 2 23/32" | UNF | 4 | I | 0.272" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 2 15/16" | UNC | 4 | 5/16" | 0.3125" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 1/4" | 2 15/16" | UNF | 4 | Q | 0.332" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 1 7/16" | 3 5/32" | UNC | 4 | U | 0.368" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 1 7/16" | 3 5/32" | UNF | 4 | 25/64" | 0.3906" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 21/32" | 3 3/8" | UNC | 4 | 27/64" | 0.4219" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 21/32" | 3 3/8" | UNF | 4 | 29/64" | 0.4531" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-12 | 1 21/32" | 3 19/32" | UNC | 4 | 31/64" | 0.4844" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 13/16" | 3 13/16" | UNC | 4 | 17/32" | 0.5313" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 1 13/16" | 3 13/16" | UNF | 4 | 37/64" | 0.5781" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 4 | 21/32" | 0.6563" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 4 1/4" | UNF | 4 | 11/16" | 0.6875" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 2 7/32" | 4 11/16" | UNC | 4 | 49/64" | 0.7656" | Square | 000000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 1/2" | 5 1/8" | UNC | 4 | 7/8" | 0.875" | Square | 000000000 | 000000 | 00000000 | 000000 | 000000000 | 000000 | 3 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 0.63" | 1.94" | Metric | 3 | 3/32" | 0.0937" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 3/4" | 2.13" | Metric | 4 | 1/8" | 0.125" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 0.88" | 2.38" | Metric | 4 | 11/64" | 0.1719" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 1" | 2 1/2" | Metric | 4 | 13/64" | 0.2031" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 1.13" | 2.72" | Metric | 4 | 17/64" | 0.2656" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 1 1/4" | 2.94" | Metric | 4 | 21/64" | 0.3281" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 1.66" | 3.38" | Metric | 4 | 13/32" | 0.4062" | Square | ——— | 0 | 000000000 | 00000 | 000000000 | 00000 | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

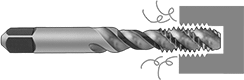

Chip-Clearing Taps

|

Spiral-Point Flute for Through Holes |

|

Spiral Flute for Blind Holes |

Remove long, stringy chips to produce cleaner threads than standard taps. The flute design prevents buildup to protect the quality of the threads and avoid damage to the tap. Since you don’t need to reverse these taps to extract chips, they also create threads faster.

High-Speed Steel—The most versatile taps resist heat and wear to stay sharp. They’re good for most metals and plastic.

Titanium Carbon Nitride (TiCN) Coated—Resist heat, chipping, and wear for three times the life of uncoated taps.

Spiral-Point Flute for Through Holes—Push chips ahead of the tap and out of through holes. Also known as gun taps.

Spiral Flute for Blind Holes—Pull chips back toward the tap so they won't build up in blind holes. When tapping brittle material like iron that creates fine or powdery debris, choose a straight-flute tap.

Plug Chamfer—Our go-to chamfer type. With a longer taper than a bottoming chamfer, they are easier to turn but won't thread as close the bottom of a hole.

Bottoming Chamfer—These taps have the shortest taper to thread close to the bottom of blind holes. They require the most force to turn, so they’re often used to finish holes started by plug-chamfer taps.

Drill Bit | Spiral-Point Flute for Through Holes | Spiral Flute for Blind Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | Chamfer Type | No. of Flutes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0-80 | 5/16" | 1 5/8" | UNF | 3/64" | 0.0469" | Square | Plug | 2 | 0000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1-64 | 3/8" | 1 11/16" | UNC | 53 Ga. | 0.0595" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1-72 | 3/8" | 1 11/16" | UNF | 53 Ga. | 0.0595" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2-56 | 7/16" | 1 3/4" | UNC | 51 Ga. | 0.067" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2-64 | 7/16" | 1 3/4" | UNF | 50 Ga. | 0.07" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3-48 | 1/2" | 1 13/16" | UNC | 47 Ga. | 0.0785" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 5/16" | 1 7/8" | UNC | 43 Ga. | 0.089" | Square | — | — | ——— | 0 | Plug | 2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 5/16" | 1 7/8" | UNC | 43 Ga. | 0.089" | Square | — | — | ——— | 0 | Bottoming | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-40 | 9/16" | 1 7/8" | UNC | 43 Ga. | 0.089" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-48 | 9/16" | 1 7/8" | UNF | 42 Ga. | 0.0935" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-40 | 5/8" | 1 15/16" | UNC | 38 Ga. | 0.1015" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-44 | 5/8" | 1 15/16" | UNF | 37 Ga. | 0.104" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 25/64" | 2" | UNC | 36 Ga. | 0.1065" | Square | — | — | ——— | 0 | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 25/64" | 2" | UNC | 36 Ga. | 0.1065" | Square | — | — | ——— | 0 | Bottoming | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 11/16" | 2" | UNC | 36 Ga. | 0.1065" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-40 | 11/16" | 2" | UNF | 33 Ga. | 0.113" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-48 | 23/32" | 2" | UNS | 2.9 mm | 0.1142" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 25/64" | 2 1/8" | UNC | 29 Ga. | 0.136" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 25/64" | 2 1/8" | UNC | 29 Ga. | 0.136" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 3/4" | 2 1/8" | UNC | 29 Ga. | 0.136" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 3/4" | 2 1/8" | UNF | 29 Ga. | 0.136" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-40 | 3/4" | 2 1/8" | UNS | 28 Ga. | 0.1405" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 1/2" | 2 3/8" | UNC | 25 Ga. | 0.1495" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 1/2" | 2 3/8" | UNC | 25 Ga. | 0.1495" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 7/8" | 2 3/8" | UNC | 25 Ga. | 0.1495" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1/2" | 2 3/8" | UNF | 21 Ga. | 0.159" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 1/2" | 2 3/8" | UNF | 21 Ga. | 0.159" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 7/8" | 2 3/8" | UNF | 21 Ga. | 0.159" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-40 | 7/8" | 2 3/8" | UNS | 20 Ga. | 0.161" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12-24 | 15/16" | 2 3/8" | UNC | 16 Ga. | 0.177" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12-28 | 15/16" | 2 3/8" | UNF | 15 Ga. | 0.18" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12-32 | 15/16" | 2 3/8" | UNEF | 13 Ga. | 0.185" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 41/64" | 2 1/2" | UNC | 7 Ga. | 0.201" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 41/64" | 2 1/2" | UNC | 7 Ga. | 0.201" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 2 1/2" | UNC | 7 Ga. | 0.201" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-24 | 1" | 2 1/2" | UNS | 4 Ga. | 0.209" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 41/64" | 2 1/2" | UNF | 3 Ga. | 0.213" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 41/64" | 2 1/2" | UNF | 3 Ga. | 0.213" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1" | 2 1/2" | UNF | 3 Ga. | 0.213" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-32 | 1" | 2 1/2" | UNEF | 5.6 mm | 0.2204" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-36 | 1" | 2 1/2" | UNS | 2 Ga. | 0.221" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-40 | 1" | 2 1/2" | UNS | 2 Ga. | 0.221" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 45/64" | 2 23/32" | UNC | F | 0.257" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 45/64" | 2 23/32" | UNC | F | 0.257" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/8" | 2 23/32" | UNC | F | 0.257" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 45/64" | 2 23/32" | UNF | I | 0.272" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 45/64" | 2 23/32" | UNF | I | 0.272" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/8" | 2 23/32" | UNF | I | 0.272" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-32 | 1 1/8" | 2 23/32" | UNEF | 9/32" | 0.2813" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 49/64" | 2 15/16" | UNC | 5/16" | 0.3125" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 49/64" | 2 15/16" | UNC | 5/16" | 0.3125" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 2 15/16" | UNC | 5/16" | 0.3125" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 49/64" | 2 15/16" | UNF | Q | 0.332" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 49/64" | 2 15/16" | UNF | Q | 0.332" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 1/4" | 2 15/16" | UNF | Q | 0.332" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-32 | 1 1/4" | 2 15/16" | UNEF | 11/32" | 0.3438" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 29/32" | 3 5/32" | UNC | U | 0.368" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 29/32" | 3 5/32" | UNC | U | 0.368" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 1 7/16" | 3 5/32" | UNC | U | 0.368" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-20 | 1 7/16" | 3 5/32" | UNF | 25/64" | 0.3906" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 61/64" | 3 3/8" | UNC | 27/64" | 0.4219" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 61/64" | 3 3/8" | UNC | 27/64" | 0.4219" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 21/32" | 3 3/8" | UNC | 27/64" | 0.4219" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 21/32" | 3 3/8" | UNF | 29/64" | 0.4531" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-28 | 1 21/32" | 3 3/8" | UNEF | 15/32" | 0.4688" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-12 | 1 21/32" | 3 19/32" | UNC | 31/64" | 0.482" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 21/32" | 3 19/32" | UNF | 33/64" | 0.509" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 13/16" | 3 13/16" | UNC | 17/32" | 0.5313" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-18 | 1 13/16" | 3 13/16" | UNF | 37/64" | 0.5781" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2" | 4 1/4" | UNC | 21/32" | 0.6563" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 2" | 4 1/4" | UNF | 11/16" | 0.689" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-9 | 2 7/32" | 4 11/16" | UNC | 49/64" | 0.767" | Square | Plug | 3 | 00000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-14 | 2 7/32" | 4 11/16" | UNF | 13/16" | 0.806" | Square | Plug | 3 | 00000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 2 1/2" | 5 1/8" | UNC | 7/8" | 0.878" | Square | Plug | 3 | 00000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-14 | 2 1/2" | 5 1/8" | UNS | 15/16" | 0.931" | Square | Plug | 3 | 00000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-7 | 2 9/16" | 5 3/4" | UNC | 1 7/64" | 1.11" | Square | Plug | 3 | 00000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M1.6 × 0.35 mm | 5/16" | 1 5/8" | Metric | 1.25 mm | 0.0492" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M1.7 × 0.35 mm | 9/32" | 1 37/64" | Metric | 3/64" | 0.0469" | Square | — | — | ——— | 0 | Bottoming | 2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M1.7 × 0.35 mm | 23/64" | 1 37/64" | Metric | 3/64" | 0.0469" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | 7/16" | 1 3/4" | Metric | 1.6 mm | 0.063" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.3 × 0.4 mm | 7/16" | 1 25/32" | Metric | 5/64" | 0.0781" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 × 0.45 mm | 1/2" | 1 13/16" | Metric | 2.05 mm | 0.0807" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.6 × 0.45 mm | 7/64" | 1 31/32" | Metric | 3/32" | 0.0938" | Square | — | — | ——— | 0 | Bottoming | 2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.6 × 0.45 mm | 15/32" | 1 31/32" | Metric | 3/32" | 0.0938" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 5/32" | 2 13/64" | Metric | 2.5 mm | 0.0984" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 5/16" | 1 15/16" | Metric | 2.5 mm | 0.0984" | Square | — | — | ——— | 0 | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 5/8" | 1 15/16" | Metric | 2.5 mm | 0.0984" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 × 0.6 mm | 11/16" | 2" | Metric | 2.9 mm | 0.1142" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 13/64" | 2 31/64" | Metric | 3.3 mm | 0.1299" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 25/64" | 2 1/8" | Metric | 3.3 mm | 0.1299" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 × 0.7 mm | 3/4" | 2 1/8" | Metric | 3.3 mm | 0.1299" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.5 mm | 7/8" | 2 3/8" | Metric | 4.5 mm | 0.1772" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 1/4" | 2 3/4" | Metric | 4.2 mm | 0.1653" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 1/2" | 2 3/8" | Metric | 4.2 mm | 0.1653" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 × 0.8 mm | 7/8" | 2 3/8" | Metric | 4.2 mm | 0.1653" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 0.75 mm | 1" | 2 1/2" | Metric | 5.25 mm | 0.2067" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 9/32" | 3 9/64" | Metric | 5 mm | 0.1968" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 5/8" | 2 1/2" | Metric | 5 mm | 0.1968" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 1" | 2 1/2" | Metric | 5 mm | 0.1968" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M7 × 1 mm | 5/16" | 3 9/64" | Metric | 6.2 mm | 0.243" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M7 × 1 mm | 1 1/8" | 2 23/32" | Metric | 6 mm | 0.2362" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1 mm | 1 1/8" | 2 23/32" | Metric | 7 mm | 0.2756" | Square | Plug | 2 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 25/64" | 3 17/32" | Metric | 6.7 mm | 0.2637" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 45/64" | 2 23/32" | Metric | 6.7 mm | 0.2637" | Square | — | — | ——— | 0 | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 1 1/8" | 2 23/32" | Metric | 6.7 mm | 0.2637" | Square | Plug | 2 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M9 × 1.25 mm | 25/64" | 3 17/32" | Metric | 7.9 mm | 0.313" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1 mm | 1 1/4" | 2 15/16" | Metric | 9 mm | 0.3543" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.25 mm | 1 1/4" | 2 15/16" | Metric | 8.75 mm | 0.3445" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 15/32" | 3 15/16" | Metric | 8.7 mm | 0.344" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 1.5 mm | 1 1/4" | 2 15/16" | Metric | 8.5 mm | 0.3346" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1 mm | 1 21/32" | 3 3/8" | Metric | 11 mm | 0.4331" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.25 mm | 1 21/32" | 3 3/8" | Metric | 10.75 mm | 0.4232" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.5 mm | 1 21/32" | 3 3/8" | Metric | 10.5 mm | 0.4134" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 35/64" | 4 21/64" | Metric | 10.5 mm | 0.414" | Square | — | — | ——— | 0 | Bottoming | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 1.75 mm | 1 21/32" | 3 3/8" | Metric | 10.2 mm | 0.4015" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 1.5 mm | 1 21/32" | 3 19/32" | Metric | 12.5 mm | 0.4921" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M14 × 2 mm | 1 21/32" | 3 19/32" | Metric | 12 mm | 0.4724" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 1.5 mm | 1 13/16" | 3 13/16" | Metric | 14.5 mm | 0.5709" | Square | Plug | 3 | 00000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 2 mm | 1 13/16" | 3 13/16" | Metric | 14 mm | 0.5512" | Square | Plug | 3 | 0000000 | 00000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M18 × 2.5 mm | 1 13/16" | 4 1/32" | Metric | 15.5 mm | 0.6102" | Square | Plug | 3 | 0000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 2.5 mm | 2" | 4 15/32" | Metric | 17.5 mm | 0.689" | Square | Plug | 3 | 0000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 3 mm | 2 7/32" | 4 29/32" | Metric | 21 mm | 0.8268" | Square | Plug | 3 | 0000000 | 000000 | — | — | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tap Sets

These sets include a variety of taps for threading holes so screws, bolts, and rods fit snugly.

High-Speed Steel—Single Thread Size Sets

|

Taper, Plug, and Bottoming Chamfer Set |

The most versatile taps resist heat and wear to stay sharp. They’re good for most metals and plastic. These sets include one of each chamfer type: Taper for starting holes and threading through holes; plug for through holes and blind holes; and bottoming for cutting the closest to the bottom of any hole.

Titanium Carbon Nitride (TiCN) Coated—Resist heat, chipping, and wear for three times the life of uncoated taps.

Taper Chamfer, Plug Chamfer, Bottoming Chamfer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Tap Sizes Included | Thread Type | Container Type | No. of Flutes | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 0-80 | UNF | Plastic Case | 2 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 2-56 | UNC | Plastic Case | 3 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 4-40 | UNC | Plastic Case | 3 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 5-40 | UNC | Plastic Case | 3 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 6-32 | UNC | Plastic Case | 3 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 6-40 | UNF | Plastic Case | 3 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 8-32 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 10-24 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 10-32 | UNF | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 12-24 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/4"-20 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/4"-28 | UNF | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 5/16"-18 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 5/16"-24 | UNF | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/8"-16 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/8"-24 | UNF | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 7/16"-14 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 7/16"-20 | UNF | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/2"-13 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/2"-20 | UNF | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 9/16"-12 | UNC | Plastic Case | 4 | Square | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 5/8"-11 | UNC | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 5/8"-18 | UNF | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-10 | UNC | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3/4"-16 | UNF | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 7/8"-9 | UNC | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1"-8 | UNC | Plastic Case | 4 | Square | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Clearing Pipe and Conduit Taps for Steel and Stainless Steel

Made of a high-vanadium alloy, these taps are harder and more wear-resistant than other high-speed steel taps. The widely spaced flutes prevent buildup that can ruin threads and keep pipe and conduit from making strong connections. Also known as interrupted-thread taps.

NPT Thread%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

Titanium Carbon Nitride (TiCN) Coated—Resist heat, chipping, and wear for three times the life of uncoated taps.

Drill Bit | Plug Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Thread Lg. | Overall Lg. | No. of Flutes | Threads per In. | Size | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cobalt Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 3/4" | 2 1/8" | 3 | 27 | Q | 0.332" | Square | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 1 1/16" | 2 7/16" | 3 | 18 | 7/16" | 0.4375" | Square | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 1 1/16" | 2 9/16" | 5 | 18 | 9/16" | 0.5625" | Square | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 1 3/8" | 3 1/8" | 5 | 14 | 45/64" | 0.7031" | Square | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 1 3/8" | 3 1/4" | 5 | 14 | 29/32" | 0.9063" | Square | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Left-Hand Thread Chip-Clearing Taps

|

Spiral-Point Flute for Through Holes |

Chips won't slow you down when creating threads to join counter-clockwise rotating parts. Left-hand threads keep components such as flywheels and propellers from loosening and spinning off. These taps force chips through the hole so there’s no buildup to damage the threads or the tap. Since you don’t need to reverse taps to extract chips, they also form threads faster than standard left-hand taps.

High-Speed Steel—The most versatile taps resist heat and wear to stay sharp. They’re good for most metals and plastic.

Titanium Carbon Nitride (TiCN) Coated—Resist heat, chipping, and wear for three times the life of uncoated taps.

Spiral-Point Flute for Through Holes—Push chips ahead of the tap and out of through holes. Also known as gun taps.

Plug Chamfer—Our go-to chamfer type. With a longer taper than a bottoming chamfer, they are easier to turn but won't thread as close the bottom of a hole.

Drill Bit | Spiral-Point Flute for Through Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | Size | Decimal Size Equiv. | Shank Type | Chamfer Type | No. of Flutes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-40 | 5/8" | 1 15/16" | UNC | 38 Ga. | 0.1015" | Square | Plug | 2 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 11/16" | 2" | UNC | 36 Ga. | 0.1065" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 3/4" | 2 1/8" | UNC | 29 Ga. | 0.136" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 7/8" | 2 3/8" | UNC | 25 Ga. | 0.1495" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 7/8" | 2 3/8" | UNF | 21 Ga. | 0.159" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 1" | 2 1/2" | UNC | 7 Ga. | 0.201" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-28 | 1" | 2 1/2" | UNF | 3 Ga. | 0.213" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 1 1/8" | 2 23/32" | UNC | F | 0.257" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-24 | 1 1/8" | 2 23/32" | UNF | I | 0.272" | Square | Plug | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 1 1/4" | 2 15/16" | UNC | 5/16" | 0.3125" | Square | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-24 | 1 1/4" | 2 15/16" | UNF | Q | 0.332" | Square | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16"-14 | 1 7/16" | 3 5/32" | UNC | U | 0.368" | Square | Plug | 3 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 1 21/32" | 3 3/8" | UNC | 27/64" | 0.4219" | Square | Plug | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-20 | 1 21/32" | 3 3/8" | UNF | 29/64" | 0.4531" | Square | Plug | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 1 13/16" | 3 13/16" | UNC | 17/32" | 0.5313" | Square | Plug | 3 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chip-Free Taps

No flutes, no chips. Press threads into material for zero buildup to slow you down or damage the tap. Since these displace rather than cut material, they create stronger, cleaner threads. They require an exact hole size, however, or tapping can be difficult and result in weak threads. Fluteless taps are faster and require more force to drive than fluted taps, so they're commonly used in production work on a milling machine. Also known as cold-forming taps.

High-Speed Steel—The most versatile taps resist heat and wear to stay sharp. They’re good for most metals.

Titanium Carbon Nitride (TiCN) Coated—Resist heat, chipping, and wear for three times the life of uncoated taps.

Bottoming Chamfer—Cut all the way to the bottom of blind holes with taps that have the shortest taper. Since these require the most force to turn, they’re often used to finish holes started by taper- or plug-chamfer taps.

Drill Bit | Bottoming Chamfer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Overall Lg. | Thread Type | No. of Flutes | Size | Decimal Size Equiv. | Shank Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Speed Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Titanium Carbon Nitride (TiCN) Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 × 0.5 mm | 5/8" | 1 15/16" | Metric | 0 | 7/64" | 0.1094" | Square | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 × 1 mm | 5/8" | 2 1/2" | Metric | 0 | 7/32" | 0.2188" | Square | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 × 1.25 mm | 11/16" | 2 23/32" | Metric | 0 | 7.4 mm | 0.2913" | Square | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||