About Gradual On/Off Valves

More

Socket-Connect Gradual On/Off Valves for Chemicals

- Valve Type: Gate

- For Use With: Water, Carbon Dioxide, Citric Acid, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Natural Gas, Phosphoric Acid, Propane, Salt Water

- Seal Material: Fluoroelastomer Rubber

For a permanent, leak-tight seal, insert unthreaded pipe into the socket ends on these valves and bond with primer and cement. To withstand aggressive and corrosive solutions in chemical-processing applications, they have a fluoroelastomer seal and a plastic body. All gradually open and close with multiple turns of the wheel handle to prevent system damage from suddenly starting and stopping flow. Valves have a nonrising stem that stays in the same position whether the valve is open or closed.

Use repair kits to replace worn-out seals.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Valves | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Repair Kits | ||||||||||

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Each | Each | ||

Socket Connect Female | |||||||||||

Dark Gray PVC Plastic Body and Polypropylene Plastic Gate | |||||||||||

| 3/4 | 37 | 200 psi @ 70° F | 40° to 140° | 2 13/16" | 5 1/8" | 2 13/16" | Nonrising | 0000000 | 000000 | 00000000 | 000000 |

| 1 | 44 | 200 psi @ 70° F | 40° to 140° | 3 5/16" | 5 7/16" | 3 5/16" | Nonrising | 0000000 | 00000 | 00000000 | 00000 |

| 1 1/2 | 144 | 200 psi @ 70° F | 40° to 140° | 3 3/4" | 8 1/16" | 3 3/4" | Nonrising | 0000000 | 000000 | 00000000 | 00000 |

| 2 | 333 | 200 psi @ 70° F | 40° to 140° | 3 15/16" | 8 9/16" | 3 15/16" | Nonrising | 0000000 | 000000 | 00000000 | 00000 |

Light Gray CPVC Plastic Body and Gate | |||||||||||

| 1/2 | 19 | 200 psi @ 70° F | 40° to 200° | 2 13/16" | 5 1/8" | 2 13/16" | Nonrising | 0000000 | 000000 | 00000000 | 00000 |

| 1 | 44 | 200 psi @ 70° F | 40° to 200° | 3 5/16" | 5 7/16" | 3 5/16" | Nonrising | 0000000 | 000000 | 00000000 | 00000 |

| 2 | 333 | 200 psi @ 70° F | 40° to 200° | 3 15/16" | 8 9/16" | 3 15/16" | Nonrising | 0000000 | 000000 | 00000000 | 00000 |

Plastic Socket-Connect Gradual On/Off Valves for Drinking Water

- Valve Type: Gate

- For Use With: Drinking Water

- Seal Material: See table

- Specifications Met: NSF/ANSI 61

Bond these valves to plastic pipe with PVC primer and cement (not included) to create a permanent, leak-tight connection in drinking water lines. Also known as gate valves, they open and close gradually to prevent damage to your system from sudden changes in flow. Turn the handle multiple times to start or stop flow. Safe for use in drinking water systems, these valves meet NSF/ANSI 61. They’re plastic, so they’re lighter in weight than metal valves.

All have a nonrising stem, which means that the handle won’t move up as the valve opens. This makes them good for underground and other low-clearance applications.

CPVC valves handle temperatures up to 200° F, so you can use them in hot drinking water applications.

Use repair kits to replace worn seals.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Valves | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Repair Kits | ||||||||||||

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | Seal Material | End-to-End Lg. | Ht. | Lg. | Stem Type | Color | Each | Each | ||

Socket Connect Female | |||||||||||||

PVC Plastic Body—Polypropylene Plastic Gate | |||||||||||||

| 1/2 | 19 | 200 psi @ 70° F | 40° to 140° | Buna-N Rubber | 2 13/16" | 5 1/8" | 2 13/16" | Nonrising | Dark Gray | 0000000 | 000000 | 00000000 | 000000 |

| 3/4 | 37 | 200 psi @ 70° F | 40° to 140° | Buna-N Rubber | 2 13/16" | 5 1/8" | 2 13/16" | Nonrising | Dark Gray | 0000000 | 00000 | 00000000 | 00000 |

| 1 | 44 | 200 psi @ 70° F | 40° to 140° | Buna-N Rubber | 3 5/16" | 5 7/16" | 3 5/16" | Nonrising | Dark Gray | 0000000 | 00000 | 00000000 | 00000 |

| 1 1/2 | 144 | 200 psi @ 70° F | 40° to 140° | Buna-N Rubber | 3 3/4" | 8 1/16" | 3 3/4" | Nonrising | Dark Gray | 0000000 | 000000 | 00000000 | 00000 |

| 2 | 333 | 200 psi @ 70° F | 40° to 140° | Buna-N Rubber | 3 15/16" | 8 9/16" | 3 15/16" | Nonrising | Dark Gray | 0000000 | 000000 | 00000000 | 00000 |

CPVC Plastic Body—Polypropylene Plastic Gate | |||||||||||||

| 1 | 44 | 200 psi @ 70° F | 32° to 200° | EPDM Rubber | 3 1/4" | 5 13/32" | 3 1/4" | Nonrising | Dark Gray | 00000000 | 000000 | 00000000 | 00000 |

| 2 | 333 | 200 psi @ 70° F | 32° to 200° | EPDM Rubber | 3 15/16" | 8 9/16" | 4 7/16" | Nonrising | Dark Gray | 00000000 | 000000 | 00000000 | 00000 |

Gradual On/Off Valves with Quick-Clamp Fittings for High Vacuum

Also known as vacuum isolation valves, these block flow so you can install and remove gauges from your system. They can also be used to add or vent gases in high-vacuum systems. Valves gradually open and close with multiple turns of the wheel handle to prevent system damage from suddenly starting and stopping flow. They connect to another quick-clamp (ISO-KF) fitting with a clamp and a ring (sold separately). All have a nonrising stem that stays in the same position whether the valve is open or closed. Body is 304 stainless steel for good corrosion resistance.

- Valve Type: Gate

- For Use With: Air

- For Tube Material: 304/304L Stainless Steel, 316/316L Stainless Steel

- Seal Material: Viton® Fluoroelastomer Rubber

- Specifications Met: ISO 2861

O'all | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | High Vacuum Connection Type | Max. Vacuum | Temp. Range, °F | Ht. | Lg. | High-Vacuum Flange Size | Sterilize With | Stem Type | Each | |

Quick Clamp | |||||||||||

304 Stainless Steel Body—316 Stainless Steel Gate | |||||||||||

| 1/2" | 1 3/16" | ISO-KF | 10 -8 torr @ 72° F | 0° to 190° | 4 1/8" | 2 1/4" | 10 | Steam (Autoclaving) | Nonrising | 00000000 | 0000000 |

| 3/4" | 1 3/16" | ISO-KF | 10 -8 torr @ 72° F | 0° to 190° | 4 1/8" | 2 1/4" | 16 | Steam (Autoclaving) | Nonrising | 00000000 | 000000 |

| 1" | 1 9/16" | ISO-KF | 10 -8 torr @ 72° F | 0° to 190° | 5 5/8" | 3" | 25 | Steam (Autoclaving) | Nonrising | 00000000 | 000000 |

| 1 1/2" | 2 1/8" | ISO-KF | 10 -8 torr @ 72° F | 0° to 190° | 6 3/8" | 3 7/8" | 40 | Steam (Autoclaving) | Nonrising | 00000000 | 000000 |

| 2" | 2 15/16" | ISO-KF | 10 -8 torr @ 72° F | 0° to 190° | 8" | 4 1/2" | 50 | Steam (Autoclaving) | Nonrising | 00000000 | 000000 |

- For Use With: Air

- O-Ring Material: Viton® Fluoroelastomer Rubber

- For Tube Material: 304/304L Stainless Steel, 316/316L Stainless Steel, Aluminum

- Inner Ring Material: 304 Stainless Steel

- Specifications Met: ISO 2861

Use these rings with quick-clamp high-vacuum fittings. They consist of a stainless steel inner ring covered by a fluoroelastomer O-ring.

Rings with screen have a stainless steel screen to filter out large particles.

| For Tube OD | For Flange OD | For High-Vacuum Flange Size | Max. Vacuum | Temp. Range, °F | Lg. | Max. Pressure | Each | |

Rings | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2" | 1.18" | 10 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 00000 |

| 3/4" | 1.18" | 16 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 0000 |

| 1" | 1.57" | 25 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 0000000 | 00000 |

| 2" | 2.95" | 50 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 0000000 | 00000 |

Rings with Stainless Steel Screen | ||||||||

| 3/4" | 1.18" | 16 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 00000 |

| 1 1/2" | 2.16" | 40 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 00000 |

| 2" | 2.95" | 50 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 00000 |

Rings with Aluminum Outer Ring | ||||||||

| 3/4" | 1.18" | 16 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | Not Rated | 00000000 | 00000 |

| 1" | 1.57" | 25 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | 100 psi @ 72° F | 0000000 | 00000 |

| 1 1/2" | 2.16" | 40 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | 75 psi @ 72° F | 0000000 | 00000 |

| 2" | 2.95" | 50 | 10 -8 torr @ 72° F | 0° to 300° | 5/16" | 50 psi @ 72° F | 0000000 | 00000 |

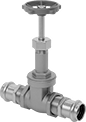

Gradual On/Off Valves with Press-Connect Fittings

- Valve Type: Gate

- For Use With: Water

- Specifications Met: MSS-SP-80

For a leak-tight connection, crimp the press-connect fittings on these valves to metal tubing with a crimping tool (not included)—no heat or soldering required. The fittings are comparable to Viega fittings. These valves open and close gradually as the wheel handle turns, preventing sudden starts and stops of flow. They’re also known as gate valves. Made of bronze, they have good corrosion resistance.

Valves with a nonrising stem keep the handle in the same position whether they’re open or closed. They’re often used in low-clearance locations.

Valves with a rising stem lift up the handle as they open and lower it as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Copper Tube Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | For Tube OD | Each | |

Nonrising Stem | |||||||

|---|---|---|---|---|---|---|---|

Press Connect Female | |||||||

Bronze Body and Gate | |||||||

| 1/2 | 17 | 200 psi @ 250° F | 32° to 250° | 5" | 5/8" | 0000000 | 0000000 |

| 3/4 | 32 | 200 psi @ 250° F | 32° to 250° | 5 3/4" | 7/8" | 0000000 | 000000 |

| 1 | 54 | 200 psi @ 250° F | 32° to 250° | 6 9/16" | 1 1/8" | 0000000 | 000000 |

| 1 1/4 | 97 | 200 psi @ 250° F | 32° to 250° | 6 13/16" | 1 3/8" | 0000000 | 000000 |

| 1 1/2 | 135 | 200 psi @ 250° F | 32° to 250° | 7 1/4" | 1 5/8" | 0000000 | 000000 |

| 2 | 230 | 200 psi @ 250° F | 32° to 250° | 9 5/16" | 2 1/8" | 0000000 | 000000 |

Rising Stem | |||||||

Press Connect Female | |||||||

Bronze Body and Gate | |||||||

| 1/2 | 17 | 200 psi @ 250° F | 32° to 250° | 5" | 5/8" | 0000000 | 000000 |

| 3/4 | 32 | 200 psi @ 250° F | 32° to 250° | 5 3/4" | 7/8" | 0000000 | 000000 |

| 1 | 54 | 200 psi @ 250° F | 32° to 250° | 6 9/16" | 1 1/8" | 0000000 | 000000 |

| 1 1/4 | 97 | 200 psi @ 250° F | 32° to 250° | 6 13/16" | 1 3/8" | 0000000 | 000000 |

| 1 1/2 | 135 | 200 psi @ 250° F | 32° to 250° | 7 1/4" | 1 5/8" | 0000000 | 000000 |

| 2 | 230 | 200 psi @ 250° F | 32° to 250° | 9 5/16" | 2 1/8" | 0000000 | 000000 |

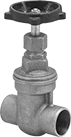

Gradual On/Off Valves with Solder-Connect Fittings

- Valve Type: Gate

- For Use With: Water, Oil

- Specifications Met: MSS-SP-80

Solder these valves to copper tubing for a permanent, leak-tight connection. They gradually open and close with multiple turns of the wheel handle to prevent system damage from suddenly starting and stopping flow.

Nonrising stems stay in the same position whether the valve is open or closed. Valves with nonrising stems are often used underground and in other low-clearance locations.

Rising stems lift as the valve opens and lower as the valve closes to provide a visual indication of whether flow is on or off. The stem is isolated from the process media for a longer service life than valves with a nonrising stem.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| For Copper Tube Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | For Tube OD | Each | |

Nonrising Stem | |||||||

|---|---|---|---|---|---|---|---|

Solder Connect Female | |||||||

Bronze Body and Gate | |||||||

| 3/8 | 5.6 | 200 psi @ 100° F | -20° to 250° | 1 5/8" | 1/2" | 0000000 | 000000 |

| 1/2 | 10.7 | 200 psi @ 100° F | -20° to 250° | 1 7/8" | 5/8" | 0000000 | 00000 |

| 3/4 | 17.6 | 200 psi @ 100° F | -20° to 250° | 2 1/2" | 7/8" | 0000000 | 00000 |

| 1 | 32 | 200 psi @ 100° F | -20° to 250° | 3" | 1 1/8" | 0000000 | 00000 |

| 1 1/4 | 54 | 200 psi @ 100° F | -20° to 250° | 3 1/4" | 1 3/8" | 0000000 | 000000 |

| 1 1/2 | 97 | 200 psi @ 100° F | -20° to 250° | 3 5/8" | 1 5/8" | 0000000 | 000000 |

| 2 | 135 | 200 psi @ 100° F | -20° to 250° | 4 5/16" | 2 1/8" | 0000000 | 000000 |

Rising Stem | |||||||

Solder Connect Female | |||||||

Bronze Body and Gate | |||||||

| 1/2 | 10.7 | 200 psi @ 100° F | -20° to 250° | 1 7/8" | 5/8" | 0000000 | 00000 |

| 3/4 | 17.6 | 200 psi @ 100° F | -20° to 250° | 2 1/2" | 7/8" | 0000000 | 00000 |

| 1 | 32 | 200 psi @ 100° F | -20° to 250° | 3" | 1 1/8" | 0000000 | 00000 |

| 1 1/4 | 54 | 200 psi @ 100° F | -20° to 250° | 3 1/4" | 1 3/8" | 0000000 | 000000 |

| 1 1/2 | 97 | 200 psi @ 100° F | -20° to 250° | 3 5/8" | 1 5/8" | 0000000 | 000000 |

| 2 | 135 | 200 psi @ 100° F | -20° to 250° | 4 5/16" | 2 1/8" | 0000000 | 000000 |