How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Shafts

More

High-Pressure Stainless Steel Threaded Pipe Fittings

Use these heavy duty fittings in high-pressure flow applications.

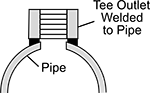

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance. Tee outlets allow you to create a threaded outlet anywhere along a pipe. They are also known as branch connectors and are comparable to Thredolet. To install, drill a hole in your pipe to match the fitting’s pipe size and weld in place.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: MSS SP-97, ASME B31.1

| Pipe Size | For Pipe Size | Ht. | Max. Pressure | Max. Steam Pressure | Each | |

304/304L Stainless Steel | ||||||

|---|---|---|---|---|---|---|

NPT Female × Butt Weld | ||||||

| 1/4 | 1/4 to 3/8 | 3/4" | 3,000 psi @ 72° F | 600 psi @ 220° F | 00000000 | 000000 |

| 1/4 | 1/2 to 36 | 3/4" | 3,000 psi @ 72° F | 600 psi @ 220° F | 00000000 | 00000 |

316/316L Stainless Steel | ||||||

NPT Female × Butt Weld | ||||||

| 1/4 | 1/4 to 3/8 | 3/4" | 3,000 psi @ 72° F | 600 psi @ 220° F | 00000000 | 00000 |

| 1/4 | 1/2 to 36 | 3/4" | 3,000 psi @ 72° F | 600 psi @ 220° F | 00000000 | 00000 |

High-Pressure Iron and Steel Threaded Pipe Fittings

These fittings can stand up to high-pressure applications. Use them in noncorrosive environments.

Tee outlets allow you to create a threaded outlet anywhere along a pipe. They are also known as branch connectors and are comparable to Thredolet. To install, drill a hole in your pipe to match the fitting’s pipe size and weld in place.

Phosphate-coated and zinc-phosphate-coated fittings offer some corrosion resistance, but aren't intended for corrosive environments.

Note: The maximum pressure listed for Class 3000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Specifications Met : ASME B31.1, ASTM A105, ASME B31.3, MSS SP-97, ASME B16.9, ASME B16.11

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

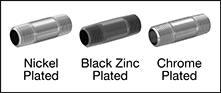

High-Pressure Plated Brass Threaded Pipe Nipples and Pipe

The plating on this pipe creates a shiny finish and provides extra protection in corrosive environments. It has the strength to handle high-pressure applications.

Nickel-plated brass pipe provides better corrosion resistance than unplated brass.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

Universal threads have a Buna-N rubber gasket to protect against leaks.

Architectural 6063 Aluminum Round Tubes

- Yield Strength: 16,000 psi

- Hardness: Brinell 55 (Soft)

- Temper: T5

- Fabrication: Extruded

- Specifications Met: ASTM B221

More corrosion resistant and easier to form than multipurpose 6061 aluminum, 6063 is primarily used for exterior railings, decorative trim, and door frames.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Anodized Architectural 6063 Aluminum Round Tubes

- Yield Strength: 16,000 psi

- Hardness: Brinell 55 (Soft)

- Temper: T5

- Fabrication: Extruded

- Specifications Met: ASTM B221

The outside of these tubes is anodized to improve wear and corrosion resistance. Often called decorative anodize, the coating provides a uniform finish that readily accepts paint and adhesive. More corrosion resistant and easier to form than multipurpose 6061 aluminum, 6063 is primarily used for exterior railings, decorative trim, and door frames.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

6 ft. Lg. | |||||||

|---|---|---|---|---|---|---|---|

| OD | ID | Heat Treatment | Finish Color | Temperature Range, °F | Straightness Tolerance | Each | |

0.219" Wall Thick. (-0.021" to 0.021" Tolerance) | |||||||

| 7/8" | 0.438" | Hardened | Clear | -320° to 212° | 0.010" per ft. | 0000000 | 000000 |

Hollow Linear Motion Shafts

Lighter than solid shafts, hollow shafts reduce your total system weight and allow you to run various media such as electrical wiring, compressed air tubing, coolants, or lubricants through the center. These shafts are smooth, hard, and wear resistant, so they work with linear bearings to reduce friction in manual and automated systems, such as those found in packing, machine tool, and material handling operations. The exterior of these shafts is turned, ground, and polished to tight diameter and straightness tolerances. The interior is unfinished.

These shafts are hardened on the surface, so they stand up to repeated motion. All have chamfered ends to remove sharp edges and reduce damage to bearings, housings, and other components during installation.

Alloy steel shafts are stronger and more wear resistant than carbon steel shafts.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

| Lg. | Lg. Tolerance | Dia. Tolerance | ID Tolerance | Surface Smoothness, microinch | Hardness Rating | Hardness | Each | |

Inch—52100 Alloy Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

3/4" Dia. (0.438" ID) | ||||||||

| __ | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 00000000 | 00 |

| 12" | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 0000000 | 000000 |

| 18" | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 0000000 | 00000 |

| 24" | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 0000000 | 000000 |

| 36" | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 0000000 | 000000 |

| 48" | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 0000000 | 000000 |

| 60" | -0.03" to 0.03" | -0.001" to -0.0005" | -0.0219" to 0.0219" | 8 | Very Hard | Rockwell C58 | 0000000 | 000000 |