Filter by

Grinding Wheel Designation

System of Measurement

For Use On

Maximum Rotation Speed

Abrasive Material

Rotation Speed

For Use With

Grit Rating

Surface Texture

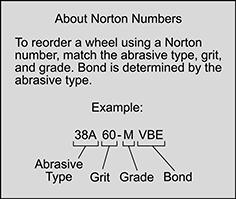

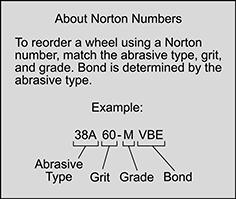

Norton Abrasive Number

Grinding Wheel Shape

Abrasive Bond Material

Arbor Hole

DFARS Specialty Metals

REACH

RoHS

Export Control Classification Number (ECCN)

Internal Diameter Toolroom Grinding Wheels for Metals

|  |

Recessed Grinding Wheel |

Wheel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Thk. | Arbor Hole Size | Max. Rotation Speed, rpm | Abrasive Material | Abrasive Bond Material | Designation | Shape | Grit (Surface Texture) | Norton Abrasive Grade | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32A Gray—VBE Bond | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Stainless Steel, Aluminum, and Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 1/4" | 43,290 | Aluminum Oxide | Synthetic Resin | Type 5 | Recessed | 60 (Rough) | K | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 32,470 | Aluminum Oxide | Synthetic Resin | Type 5 | Recessed | 60 (Rough) | K | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 3/8" | 25,970 | Aluminum Oxide | Synthetic Resin | Type 5 | Recessed | 60 (Rough) | K | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 3/8" | 21,640 | Aluminum Oxide | Synthetic Resin | Type 5 | Recessed | 60 (Rough) | K | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | 3/8" | 16,230 | Aluminum Oxide | Synthetic Resin | Type 5 | Recessed | 60 (Rough) | K | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1 1/2" | 5/8" | 16,230 | Aluminum Oxide | Synthetic Resin | Type 5 | Recessed | 60 (Rough) | K | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shaped Norton Toolroom Grinding Wheels for Metals

Wheel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Thk. | Arbor Hole Size | Max. Rotation Speed, rpm | Abrasive Material | Abrasive Bond Material | Designation | Shape | Grit (Surface Texture) | Norton Abrasive Grade | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

38A White—VBE Bond | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel and Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | K | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32A Purple—VBE Bond | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 3/4" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 3/4" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 60 (Rough) | I | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 60 (Rough) | I | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 1" | 1 1/4" | 3,105 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 60 (Rough) | I | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 1 1/2" | 5" | 1,800 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel, Stainless Steel, Iron, and Nickel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | H | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32AA Purple—VTR Bond | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel, Stainless Steel, Iron, and Nickel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 3/4" | 1 1/4" | 3,600 | Aluminum Oxide/Ceramic Alumina Blend | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide/Ceramic Alumina Blend | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5SG Blue—VS Bond | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Ceramic Alumina | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14" | 1 1/2" | 5" | 1,800 | Ceramic Alumina | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | I | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel and Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Ceramic Alumina | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | J | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Ceramic Alumina | Vitrified Clay | Type 5 | Recessed | 60 (Rough) | J | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy-Removal Norton Toolroom Grinding Wheels for Metals

|  |

Recessed Grinding Wheel |

Wheel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Thk. | Arbor Hole Size | Max. Rotation Speed, rpm | Abrasive Material | Abrasive Bond Material | Designation | Shape | Grit (Surface Texture) | Norton Abrasive Grade | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

32A Purple—VBEP Bond | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Steel and Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 1" | 1 1/4" | 3,600 | Aluminum Oxide | Vitrified Clay | Type 5 | Recessed | 46 (Rough) | H | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||