Filter by

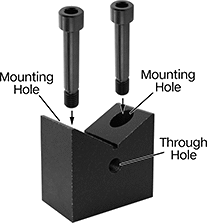

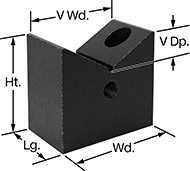

V-Block Type

Workpiece Diameter

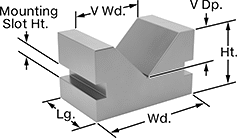

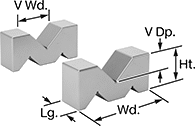

Length

V Width

V-Block Style

V Depth

Width

Height

Sold As

DFARS Specialty Metals

Export Control Classification Number (ECCN)

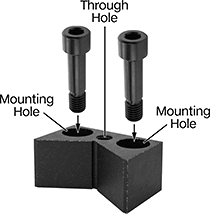

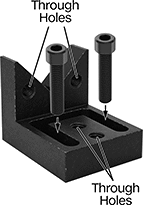

Through-Hole Type

Finish

V-Blocks

|  |  |

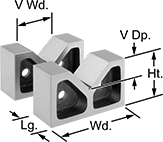

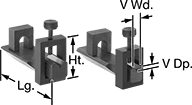

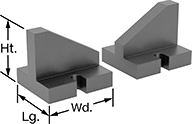

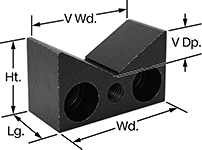

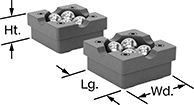

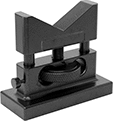

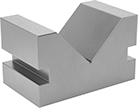

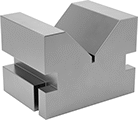

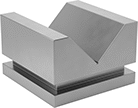

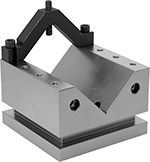

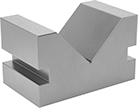

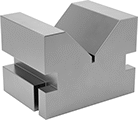

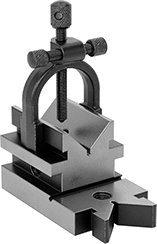

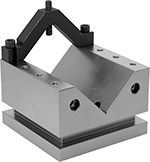

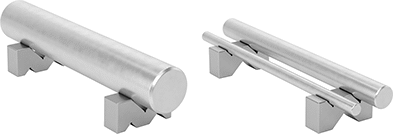

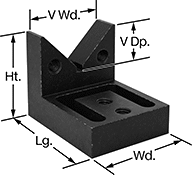

Style A | Style B | Style C |

|  |  |

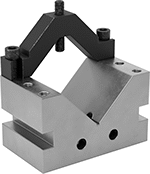

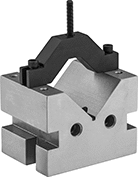

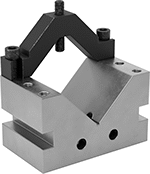

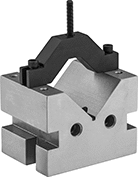

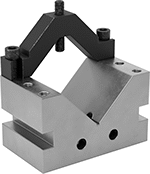

Style A with Clamp | Style B with Clamp | Style C with Clamp |

|  |  |

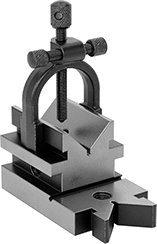

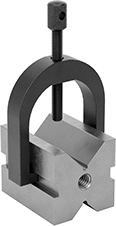

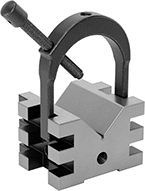

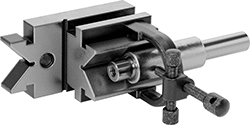

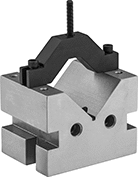

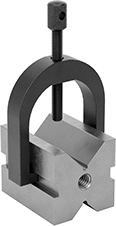

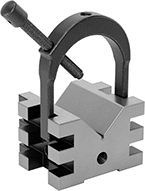

Style D with Clamp | Style D with Clamp (Side Orientation) | Style E with Clamp |

| ||

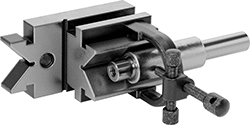

Style F with Clamp (45° Position Shown) |

Sold Individually

|  |  |

Style A | Style B | Style C |

|  |  |

Style A with Clamp | Style B with Clamp | Style C with Clamp |

|  | |

Style D with Clamp | Style D with Clamp (Side Orientation) |

|

V-Blocks | Replacement Clamps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

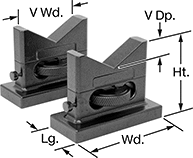

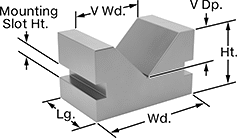

Style | Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Dia. | Squareness | Parallel | Mounting Slot Ht. | Machinable | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | — | — | — | 0.0002" | 0.0002" | 3/8" | Yes | 0000000 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | — | — | — | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | — | — | — | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | — | — | — | 0.0003" | 0.0003" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks with Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardened Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1/8" | 1 5/16" | 3 1/2" | 1 7/8" | 1 7/8" | 90° | 5/8" | 1 1/8" | 3 | 3/8"-16 | — | 0.0002" | 0.0002" | 1/2" | No | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair

|  |  |  |

Style A | Style B | Style C | Style A with Clamp |

|  |  |  |

Style B with Clamp | Style C with Clamp | Style E with Clamp | Style F with Clamp (45° Position Shown) |

|

V-Blocks | Replacement Clamps | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Dia. | Squareness | Parallel | Mounting Slot Ht. | Machinable | Pair | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | — | — | — | 0.0002" | 0.0002" | 3/8" | Yes | 0000000 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | — | — | — | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | — | — | — | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | — | — | — | 0.0003" | 0.0003" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks with Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | Yes | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | Yes | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardened Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 1 5/8" | 2 1/2" | 2 1/2" | 2" | 90° | 3/4" | 1 1/2" | 2 | — | 5/16" | 0.0002" | 0.0002" | 3/8" | No | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 3 3/4" | 3" | 5" | 3" | 90° | 1 5/8" | 3 1/4" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32" | 5 1/4" | 6" | 7" | 4" | 90° | 2 1/2" | 4 15/16" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/32" | 2 7/8" | 3" | 4" | 3" | 90° | 1 3/16" | 2 5/16" | 2 | — | 5/16" | 0.0002" | 0.0002" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 5/32" | 4 3/8" | 6" | 6" | 4" | 90° | 2" | 4" | 2 | — | 7/16" | 0.0003" | 0.0003" | 5/8" | No | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/8" | 1" | 1 5/8" | 1 1/4" | 1 1/4" | 90° | 7/16" | 13/16" | 1 | 1/4"-20 | — | 0.0002" | 0.0002" | 1/4" | No | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | 1/8" | 2" | 2 1/2" | 3" | 2" | 90° | 3/4" | 1 1/2" | 1 | 3/8"-16 | — | 0.0002" | 0.0002" | 3/8" | No | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

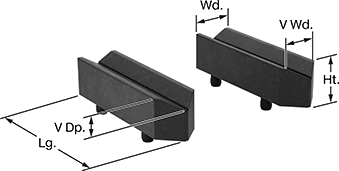

Economy V-Blocks

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

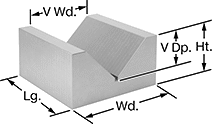

No. of Vees | For Max. Workpiece Dia. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Squareness | Parallel | Material | Machinable | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1" | 1 1/4" | 2" | 1 7/8" | 90° | 1/2" | 1" | Not Rated | 0.0019" | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1 3/4" | 15/16" | 2" | 1 1/4" | 90° | 1/8" | 1" | 0.0012" | 0.0012" | Iron | Yes | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 3/8" | 1 1/4" | 3" | 2 3/8" | 90° | 13/16" | 1 3/4" | 0.0012" | 0.0012" | Iron | Yes | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 2 15/16" | 1 5/8" | 4" | 2 5/8" | 90° | 1" | 2 3/16" | 0.0012" | 0.0012" | Iron | Yes | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3 1/8" | 2" | 5" | 3 3/16" | 90° | 1 1/8" | 2 3/8" | 0.0016" | 0.0016" | Iron | Yes | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4 5/16" | 2 1/2" | 6" | 3 1/2" | 90° | 1 1/2" | 3 3/16" | 0.002" | 0.002" | Iron | Yes | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4 1/2" | 5 1/2" | 8" | 8" | 90° | 2 1/4" | 4 1/2" | Not Rated | 0.0019" | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4 15/16" | 2" | 6" | 4" | 90° | 2 1/8" | 4 3/16" | 0.002" | 0.002" | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 4 15/16" | 4" | 7" | 5 1/2" | 90° | 1 11/16" | 3 5/8" | 0.002" | 0.002" | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5" | 6 5/8" | 10" | 10" | 90° | 2 1/2" | 5" | Not Rated | 0.0019" | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 6 1/4" | 4" | 8" | 5 1/2" | 90° | 2" | 4" | 0.0024" | 0.0024" | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 6 5/16" | 2 1/2" | 7 1/4" | 5 1/4" | 90° | 2 5/8" | 5 1/8" | 0.0024" | 0.0024" | Iron | Yes | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 7 7/8" | 2 7/8" | 8 7/8" | 6 1/2" | 90° | 3 7/16" | 6 11/16" | 0.0024" | 0.0024" | Iron | Yes | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

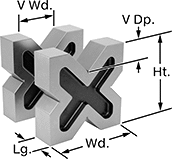

| 4 | 2" | 1 3/8" | 3 3/4" | 2 3/4" | 90° | 1" 13/16" 5/8" 3/8" | 2" 1 3/16" 1 9/16" 3/4" | 0.0012" | Not Rated | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 3/8" | 1 3/8" | 4 3/4" | 4 3/4" | 90° | 1 3/16" 1" 13/16" 5/8" | 2 3/8" 1 9/16" 2" 1 3/16" | 0.0012" | Not Rated | Iron | Yes | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Miniature V-Blocks

For Workpiece Dia. | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Pieces | Min. | Max. | Lg. | V Angle | V Dp. | Squareness | Parallel | Material | Machinable | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks with Clamp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/32" | 9/32" | 2 3/8" | 90° | 1/8" | 0.0002" | 0.0002" | Steel | No | 1 V-Block for 1/32" to 5/32" Workpieces—5/8" Wd. × 1" Ht. × 1/4" V Wd. 1 V-Block for 3/64" to 9/32" Workpieces—3/4" Wd. × 1 1/4" Ht. × 5/16" V Wd. | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

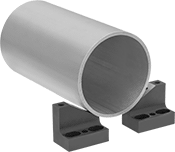

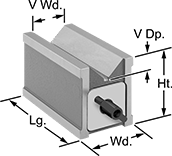

Any-Size V-Blocks

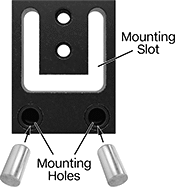

Slotted Mounting Holes

For Workpiece Dia. | Tolerance | Mounting Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. | Max. | Lg. | Wd. | Ht. | Squareness | Parallel | No. of | Wd. | Mounting Fasteners Included | Material | Machinable | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 24" | 3" | 3 1/2" | 3" | 0.002" | 0.001" | 2 | 1/2" | No | Steel | Yes | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

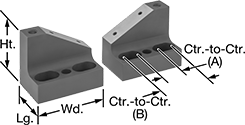

Counterbored Mounting Holes

For Workpiece Dia. | Tolerance | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. | Max. | Lg. | Wd. | Ht. | Squareness | Parallel | No. of | For Screw Size | Ctr.-to-Ctr. (A) | Ctr.-to-Ctr. (B) | Mounting Fasteners Included | Material | Machinable | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 24" | 2 1/4" | 3 1/2" | 3" | 0.001" | 0.001" | 2 | 1/2" | 1 1/2" | 2 1/2" | No | Steel | No | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three-Way V-Blocks

|  |

For Workpiece Dia. | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

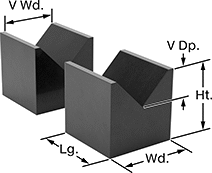

No. of Vees | Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Squareness | Parallel | Material | Machinable | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/8" | 1 1/4" | 3/4" | 2" | 15/16" | 90° | 7/16" 5/16" 7/32" | 15/16" 21/32" 1/2" | 0.0002" | 0.0002" | Hardened Steel | No | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/8" | 1 31/32" | 15/16" | 3" | 1 3/8" | 90° | 11/16" 7/16" 9/32" | 1 15/32" 15/16" 5/8" | 0.0002" | 0.0002" | Hardened Steel | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/8" | 2 11/16" | 1 5/16" | 4" | 2 1/16" | 90° | 15/16" 9/16" 3/8" | 1 31/32" 1 3/16" 25/32" | 0.0002" | 0.0002" | Hardened Steel | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1/8" | 3 7/16" | 1 3/4" | 5" | 2 3/4" | 90° | 1 3/16" 11/16" 15/32" | 2 15/32" 1 15/32" 1 1/32" | 0.0002" | 0.0002" | Hardened Steel | No | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

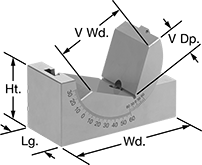

Adjustable-Angle V-Blocks

Tolerance | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Workpiece Dia. | Lg. | Wd. | Ht. | Accuracy | Range of Motion | V Angle | V Dp. | V Wd. | Squareness | Parallel | Material | Machinable | Container Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1 3/4" | 3 3/4" | 2" | ±0.003° | 0° to 90° | 90° | 1 5/32" | 1 1/8" | 0.0002" | 0.0002" | Steel | No | Wood Case | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic V-Blocks

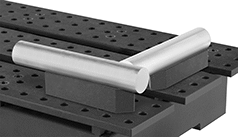

Precise-Positioning V-Blocks for Grid Fixtures

Vertical Mount with Counterbored Mounting Holes

V-Blocks | Precision Shoulder Screws | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Type | Squareness | Parallel | No. of | Screw Size | Mounting Fasteners Included | Material | Machinable | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold Individually | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5" | 2" | 3 1/4" | 3" | 120° | 1" | 3" | 1 | 1/2"-13 | Threaded | 0.001" | 0.001" | 2 | 1/2" | No | Black-Oxide Steel | No | Bushings | 0000000 | 000000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 9 1/2" | 2" | 5 1/4" | 5 1/2" | 120° | 1 1/2" | 5" | 1 | 1/2"-13 | Threaded | 0.001" | 0.001" | 4 | 1/2" | No | Black-Oxide Steel | No | Bushings | 0000000 | 00000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Horizontal Mount with Counterbored Mounting Holes

V-Blocks | Precision Shoulder Screws | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Type | Squareness | Parallel | No. of | Screw Size | Mounting Fasteners Included | Material | Machinable | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold Individually | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5" | 1 1/2" | 3 1/4" | 2" | 120° | 7/8" | 3" | 1 | 1/2"-13 | Threaded | 0.001" | 0.001" | 2 | 1/2" | No | Black-Oxide Steel | No | Bushings | 0000000 | 000000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5" | 1 1/2" | 5 1/4" | 2 1/2" | 120° | 1 1/2" | 5" | 1 | 1/2"-13 | Threaded | 0.001" | 0.001" | 4 | 1/2" | No | Black-Oxide Steel | No | Bushings | 0000000 | 00000000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

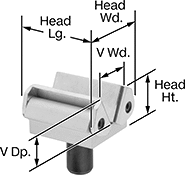

Flange Mount with Straight Mounting Holes

|  |  |

V-Blocks | Pull-Out Dowel Pins | Socket-Head Screws | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Workpiece Dia. | Through Holes | Tolerance | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | No. of | Thread Size | Type | Squareness | Parallel | No. of | Screw Size | Mounting Slot Wd. | Mounting Fasteners Included | Material | Machinable | Includes | Each | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold Individually | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3 1/8" | 4" | 3 1/8" | 3 1/8" | 90° | 1 1/2" | 2 7/8" | 4 | 1/2"-13 | Threaded | 0.001" | 0.001" | 2 | 1/2" | 1/2" | No | Black-Oxide Steel | No | Bushings | 0000000 | 000000000 | 000000000 | 00000 | 1 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Inspection V-Blocks

For Workplace Dia. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

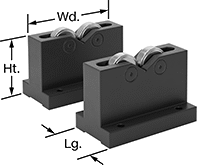

Min. | Max. | Max. Workpiece Cap., lb. | Ball Dia. | Roller Dia. | Lg. | Wd. | Ht. | Total Indicated Runout (TIR) Accuracy | Parallel Tolerance | Material | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Support | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/64" | 2 1/2" | 220 | 1/2" | — | 2 1/4" | 2 1/4" | 2" | — | — | Iron | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5" | 1,100 | 1" | — | 3 1/2" | 3 1/2" | 2 1/2" | — | — | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 15" | 2,000 | 1 1/2" | — | 4 3/4" | 4 3/4" | 3 7/8" | — | — | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball Bearing Support | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/8" | 2,200 | — | 1 3/4" | 3 1/4" | 6" | 4" | 0.0002" | 0.0005" | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 2 3/4" | 1,100 | — | 1 5/8" | 2 1/2" | 6" | 4" | 0.0002" | 0.0005" | Iron | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 7 3/4" | 2,200 | — | 2 3/4" | 4" | 9" | 6" | 0.0002" | 0.0005" | Iron | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granite Inspection V-Blocks

For Workplace Dia. | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. | Max. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Squareness | Parallel | Material | Certificate Type | Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inspection Grade A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 3" | 3" | 3" | 90° | 1 1/4" | 2 1/2" | 0.0002" | 0.0002" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 4 1/2" | 6" | 6" | 6" | 90° | 2 1/2" | 5" | 0.0002" | 0.0002" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Laboratory Grade AA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2" | 3" | 3" | 3" | 90° | 1 1/4" | 2 1/2" | 0.0001" | 0.0001" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 4 1/2" | 6" | 6" | 6" | 90° | 2 1/2" | 5" | 0.0001" | 0.0001" | Black Granite | Accuracy Certificate Traceable to NIST | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Height V-Blocks

For Workpiece Dia. | Tolerance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Min. | Max. | Max. Workpiece Cap., lb. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Adjustment Dial Graduations | Squareness | Parallel | Material | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sold as Matched Pair | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5" | 1,000 | 1 3/4" | 4" | 3" to 3 1/2" | 120° | 3/4" | 2 9/16" | 0.001" | Not Rated | 0.001" | Iron | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Blocks for Magnetic Workholding

V-Blocks for Welding

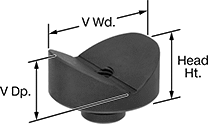

Single Stud

|  |  |

Pivoting V-Blocks Shown In Use | Fixed V-Blocks | Pivoting V-Blocks |

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. Workpiece Dia. | Dia. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Stud Dia. | Material | Machinable | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 1 5/8" | — | — | 21/32" | 120° | 13/32" | 1 7/16" | 5/8" | Black-Oxide Steel | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 3 3/16" | — | — | 1 13/32" | 150° | 19/32" | 3 1/16" | 5/8" | Black-Oxide Steel | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pivoting V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | — | 2 1/8" | 2" | 1 1/8" | 60° | 27/32" | 1" | 5/8" | Zinc-Plated Steel | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Multiple Studs

|  |

Mounting Studs Installed |

For Max. Workpiece Dia. | Lg. | Wd. | Ht. | V Angle | V Dp. | V Wd. | Stud Dia. | Material | Machinable | Includes | Pair | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Fixed V-Blocks | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 8 1/4" | 2 1/4" | 2" | 120° | 1/2" | 1 11/16" | 5/8" | Black-Oxide Steel | No | Four Mounting Studs | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||