About Actuated On/Off Valves

More

About On/Off Valves

More

Fast-Acting Panel-Mount Threaded On/Off Valves

Start or stop flow with the flip of a toggle switch or the push of a button. These valves are often used in testing and sampling applications where you need to dispense a small amount of liquid. They fit through a cutout, so the body of the valve stays safe inside your instrumentation panel.

Nickel-plated brass valves resist corrosion better than plain brass valves. Spring-return valves automatically close when you release the toggle or push button. They’re ideal for intermittent use and precise flow control to prevent spills.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Stem

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Seal Material: Buna-N Rubber Seal

| Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Push-Button Material | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × UNF Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 0.1 | 125 psi @ 70° F | -40° to 180° | Normally Closed | Spring | Plastic | 5/16" | 15/32" | 0000000 | 000000 |

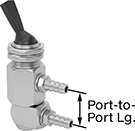

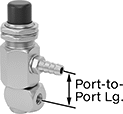

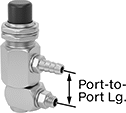

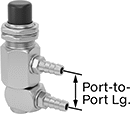

Swivel On/Off Valves with Barbed Fittings

For easy installation from any direction, the body on these valves swivels 360°. They have barbs to securely grip tubing. Often used in testing and sampling applications, they quickly open and close with a toggle or button.

Toggle-switch valves stay open until you flip them closed. Since they don’t need to be held open, they’re often used to dispense large samples. The toggle’s position shows you if they’re open or closed.

Push-button valves open when you press the button. When released, the button springs back and automatically stops flow. They’re ideal for intermittent use and controlling flow to avoid spills.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Stem

- For Use With: Air, Oil, Water

- Seal Material: Buna-N Rubber

| Thread Size | For Tube ID | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Return Actuation | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × Barbed | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Manual | 9/16" | 15/32" | 0000000 | 000000 |

UNF Male × Barbed | |||||||||

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Manual | 9/16" | 15/32" | 0000000 | 00000 |

Barbed × Barbed | |||||||||

| __ | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Manual | 9/16" | 15/32" | 0000000 | 00000 |

- Valve Type: Stem

- For Use With: Air, Oil, Water

- Seal Material: Buna-N Rubber

| Thread Size | For Tube ID | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Valve Starting Position | Return Actuation | Port-to-Port Lg. | Panel Cutout Dia. | Each | |

UNF Female × Barbed | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 9/16" | 15/32" | 0000000 | 000000 |

UNF Male × Barbed | ||||||||||

| 10-32 | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 9/16" | 15/32" | 0000000 | 00000 |

Barbed × Barbed | ||||||||||

| __ | 1/8" | 0.1 | 125 psi @ 100° F | -25° to 180° | Normally Closed | Spring | 9/16" | 15/32" | 0000000 | 00000 |

High-Purity Air-Driven Diverting Valves for Food and Beverage

- Valve Type: Plug

- For Use With: Beverage, Food

- Seal Material: EPDM Rubber

- Specifications Met: 3-A Certified 53-06

Often used in sanitary valve manifolds, these valves can be cleaned in place to eliminate the risk of cross contamination in food, beverage, and dairy lines. They are 3-A certified and electropolished to a 23 Ra finish for smooth internal surfaces that prevent product buildup and inhibit bacteria growth to maintain sanitary standards. All have sanitary quick-clamp fittings for easy disassembly. Valves operate on compressed air to automatically divert flow between ports more quickly than motor-driven valves. You must control the air to the actuator using either an electric pilot valve (not included) or a manual on/off valve (not included). Body is 316 stainless steel for excellent corrosion resistance. The actuator is secured to the valve body with a bracket for easy disassembly, maintenance, and repair.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Air | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Range, psi | Connection | Max. Temp., °F | Actuation Time | Valve Lg. | Port-to-Port Lg. | Interior Smoothness | Each | |

316 Stainless Steel Body—Quick Clamp × Quick Clamp × Quick Clamp | ||||||||||||

Single Acting: Air-to-Divert / Spring Return | ||||||||||||

| 1" | L-Pattern, U-Pattern | 15 | 175 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190° | 2 sec. | 3 7/16" | 2 1/4" | 23 Ra | 0000000 | 000000000 |

| 2" | L-Pattern, U-Pattern | 54 | 75 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190° | 2 sec. | 5 1/16" | 3 1/8" | 23 Ra | 0000000 | 00000000 |

| 3" | L-Pattern, U-Pattern | 119 | 70 psi @ 190° F | 70 to 115 | 1/4 NPT Female | 190° | 2 sec. | 6 9/16" | 3 7/8" | 23 Ra | 0000000 | 00000000 |

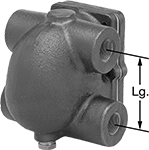

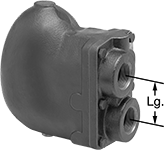

Energy-Saving Iron Steam Traps

Also known as thermostatic steam traps, these vent cool air and condensate to increase energy efficiency in your steam lines. The vent on these steam traps is normally open, allowing condensate and air to flow out. The vent closes immediately when steam enters to prevent energy loss. Use them with heat exchangers, air-heating coils, and drip stations in steam lines.

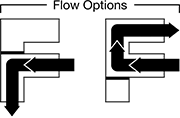

Style A has an inlet and an outlet on each side to connect inline or parallel steam and condensate lines.

Style B has an inlet and an outlet on the same side to connect parallel steam and condensate lines.

| Style | Pipe Size | Thread Type | Gender | Pipeline Orientation | Max. Pressure, psi | Max. Temp., °F | Condensate Capacity, lbs./hr. | Lg. | Ht. | Includes | Each | |

Iron with Stainless Steel Float | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 3/4 | NPT | Female | Horizontal | 15 | 250° | 1,075 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 0000000 |

| A | 3/4 | NPT | Female | Horizontal | 30 | 270° | 1,370 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 3/4 | NPT | Female | Horizontal | 75 | 320° | 1,450 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 3/4 | NPT | Female | Horizontal | 125 | 350° | 1,190 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 15 | 250° | 1,075 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 30 | 270° | 1,370 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 75 | 320° | 1,450 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 125 | 350° | 1,190 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 1/4 | NPT | Female | Horizontal | 15 | 250° | 2,340 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 1/4 | NPT | Female | Horizontal | 30 | 270° | 2,000 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| B | 1 1/4 | NPT | Female | Horizontal | 75 | 320° | 5,400 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/4 | NPT | Female | Horizontal | 125 | 350° | 4,500 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 15 | 250° | 7,600 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 30 | 270° | 7,000 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 75 | 320° | 5,400 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 125 | 350° | 4,500 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 2 | NPT | Female | Horizontal | 15 | 250° | 10,900 | 4 15/16" | 9 1/8" | __ | 0000000 | 000000 |

| B | 2 | NPT | Female | Horizontal | 30 | 270° | 10,000 | 4 15/16" | 9 1/8" | __ | 0000000 | 00000000 |

| B | 2 | NPT | Female | Horizontal | 75 | 320° | 7,700 | 4 15/16" | 9 1/8" | __ | 0000000 | 00000000 |

| B | 2 | NPT | Female | Horizontal | 125 | 350° | 6,600 | 4 15/16" | 9 1/8" | __ | 0000000 | 00000000 |