About Hex Head Screws and Bolts

More

Tight-Spot Hex Head Screws

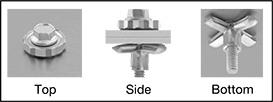

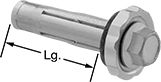

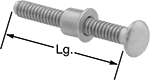

A high-strength alternative to blind rivets, use these screws when only one side of the material is accessible. To install, hold the washer in place with a wrench, and then use a hex socket to turn the screw. When the screw is tightened, the attached nut expands the sleeve to create a strong clamping force on the back of the material. Dimensions meet ISO 4017 (formerly DIN 933) specifications. Length is measured from under the head.

Head, mm | Washer | Sleeve | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Material Thick. | For Hole Size | Drill Bit Size | Lg. | Threading | Thread Spacing | Wd. | Ht. | O-Ring Material | OD | Wd. | Thick. | OD | Lg. | Tensile Strength, psi | Shear Strength | Specifications Met | Each | |

Zinc-Plated Class 8.8 Steel | ||||||||||||||||||

M8 × 1.25 mm | ||||||||||||||||||

| 1/8"-7/8" | 9/16" | 9/16" | 1 3/4" | Fully Threaded | Coarse | 13 | 5.3 | __ | 0.875" | 3/4" | 3/16" | 35/64" | 1 3/16" | 110,000 | 69,600 lbs./sq. in. | ISO 4017, DIN 933 | 000000000 | 000000 |

| 7/8"-1 5/8" | 9/16" | 9/16" | 2 9/16" | Fully Threaded | Coarse | 13 | 5.3 | __ | 0.875" | 3/4" | 3/16" | 35/64" | 1 15/16" | 110,000 | 69,600 lbs./sq. in. | ISO 4017, DIN 933 | 000000000 | 00000 |

| 1 5/8"-2 3/8" | 9/16" | 9/16" | 3 3/8" | Fully Threaded | Coarse | 13 | 5.3 | __ | 0.875" | 3/4" | 3/16" | 35/64" | 2 11/16" | 110,000 | 69,600 lbs./sq. in. | ISO 4017, DIN 933 | 000000000 | 00000 |

M10 × 1.5 mm | ||||||||||||||||||

| 1/8"-7/8" | 3/4" | 3/4" | 2" | Fully Threaded | Coarse | 16 | 6.4 | __ | 1.125" | 15/16" | 1/4" | 45/64" | 1 3/16" | 110,000 | 69,600 lbs./sq. in. | ISO 4017 | 000000000 | 00000 |

| 7/8"-1 5/8" | 3/4" | 3/4" | 2 1/2" | Fully Threaded | Coarse | 16 | 6.4 | __ | 1.125" | 15/16" | 1/4" | 45/64" | 1 7/8" | 110,000 | 69,600 lbs./sq. in. | ISO 4017 | 000000000 | 00000 |

| 1 5/8"-2 3/8" | 3/4" | 3/4" | 3 5/16" | Fully Threaded | Coarse | 16 | 6.4 | __ | 1.125" | 15/16" | 1/4" | 45/64" | 2 5/8" | 110,000 | 69,600 lbs./sq. in. | ISO 4017 | 000000000 | 00000 |

M12 × 1.75 mm | ||||||||||||||||||

| 1/8"-1" | 13/16" | 13/16" | 2 1/8" | Fully Threaded | Coarse | 18 | 7.5 | __ | 1.25" | 1 3/16" | 1/4" | 25/32" | 1 3/8" | 110,000 | 69,600 lbs./sq. in. | ISO 4017 | 000000000 | 00000 |

| 1"-1 13/16" | 13/16" | 13/16" | 2 7/8" | Fully Threaded | Coarse | 18 | 7.5 | __ | 1.25" | 1 3/16" | 1/4" | 25/32" | 2 1/4" | 110,000 | 69,600 lbs./sq. in. | ISO 4017 | 000000000 | 00000 |

| 1 13/16"-2 3/4" | 13/16" | 13/16" | 3 3/4" | Fully Threaded | Coarse | 18 | 7.5 | __ | 1.25" | 1 3/16" | 1/4" | 25/32" | 3 1/8" | 110,000 | 69,600 lbs./sq. in. | ISO 4017 | 000000000 | 00000 |

M16 × 2 mm | ||||||||||||||||||

| 1/2"-1 1/8" | 1 1/16" | 1 1/16" | 2 5/8" | Fully Threaded | Coarse | 24 | 10 | Rubber | 1.5" | 1 7/16" | 5/16" | 1 1/64" | 1 5/8" | 110,000 | 69,600 lbs./sq. in. | ISO 4017, DIN 933 | 000000000 | 00000 |

| 1 1/8"-2" | 1 1/16" | 1 1/16" | 3 5/8" | Fully Threaded | Coarse | 24 | 10 | Rubber | 1.5" | 1 7/16" | 5/16" | 1 1/64" | 2 1/2" | 110,000 | 69,600 lbs./sq. in. | ISO 4017, DIN 933 | 000000000 | 00000 |

| 2"-2 13/16" | 1 1/16" | 1 1/16" | 4 7/16" | Fully Threaded | Coarse | 24 | 10 | Rubber | 1.5" | 1 7/16" | 5/16" | 1 1/64" | 3 5/16" | 110,000 | 69,600 lbs./sq. in. | ISO 4017, DIN 933 | 000000000 | 00000 |

18-8 Stainless Steel Hex-Drive Rivets

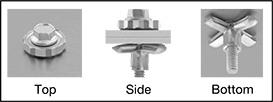

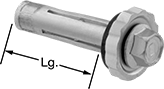

18-8 stainless steel has good corrosion resistance. Also known as fab-lock fasteners, these rivets consist of a sleeved screw with hex-washer head. The sleeve fans out when installed to resist vibration, expansion, and contraction.

Rivets install with a wrench and socket and require access to only one side of the material. For faster installation, use the tool for hex-drive rivets with an adjustable torque power driver (each sold separately).

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Thread Size | Washer Dia. | Shear Strength, lbs. | Tensile Strength | Washer Material | Sleeve Material | Pkg. Qty. | Pkg. | |

5/16" Hex Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.062"-0.25" | 1.373" | 0.313" | 5/16" | 0.688" | 0.375" | 10-24 | 0.5" | 1,950 | Not Rated | EPDM Rubber | 5052 Aluminum | 5 | 000000000 | 000000 |

| 0.25"-0.5" | 1.612" | 0.313" | 5/16" | 0.688" | 0.375" | 10-24 | 0.5" | 1,950 | Not Rated | EPDM Rubber | 5052 Aluminum | 5 | 000000000 | 00000 |

| 0.5"-0.75" | 1.807" | 0.313" | 5/16" | 0.688" | 0.375" | 10-24 | 0.5" | 1,950 | Not Rated | EPDM Rubber | 5052 Aluminum | 5 | 000000000 | 00000 |

| Material | No. of Pieces | Includes | Each | |

| Steel | 2 | Sleeve Socket | 000000000 | 0000000 |

Steel Hex-Drive Rivets

Also known as fab-lock fasteners, these rivets consist of a sleeved screw with hex-washer head. The sleeve fans out when installed to resist vibration, expansion, and contraction.

Rivets install with a wrench and socket and require access to only one side of the material. For faster installation, use the tool for hex-drive rivets with an adjustable torque power driver (each sold separately).

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Thread Size | Washer Dia. | Shear Strength, lbs. | Tensile Strength, lbs. | Washer Material | Sleeve Material | Pkg. Qty. | Pkg. | |

5/16" Hex Wd. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.062"-0.25" | 1.373" | 0.313" | 5/16" | 0.688" | 0.375" | 10-24 | 0.5" | 2,150 | 200 | EPDM Rubber | 5052 Aluminum | 10 | 000000000 | 000000 |

| 0.25"-0.5" | 1.612" | 0.313" | 5/16" | 0.688" | 0.375" | 10-24 | 0.5" | 2,150 | 200 | EPDM Rubber | 5052 Aluminum | 10 | 000000000 | 00000 |

| 0.5"-0.75" | 1.807" | 0.313" | 5/16" | 0.688" | 0.375" | 10-24 | 0.5" | 2,150 | 130 | EPDM Rubber | 5052 Aluminum | 5 | 000000000 | 00000 |

| Material | No. of Pieces | Includes | Each | |

| Steel | 2 | Sleeve Socket | 000000000 | 0000000 |

Locking-Collar Rivets

Also known as magna-grip lockbolts, these are the strongest rivets we offer. Consisting of a ribbed rivet and a collar (sold separately), they have the holding power to withstand excessive vibration, expansion, and contraction.

Installation requires access to both sides of the material and a locking collar rivet tool. The tool pulls the rivet to the collar, clinches it in place, and clips off any excess length.

Rivets | Collars | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Material Thick. | Lg. | For Hole Size | For Drill Bit Size | Head Dia. | Head Ht. | Shear Strength, lbs. | Tensile Strength, lbs. | Material | Pkg. Qty. | Pkg. | Flange Dia. | Flange Ht. | Pkg. Qty. | Pkg. | ||

3/16" Dia. | ||||||||||||||||

| 0.063"-0.625" | 1.875" | 0.203" | 7/32" | 0.394" | 0.125" | 1,700 | 1,400 | Zinc-Plated Steel | 10 | 000000000 | 00000 | 0.385" | 0.052" | 10 | 000000000 | 00000 |

| 0.313"-1.25" | 2.75" | 0.203" | 7/32" | 0.394" | 0.125" | 1,700 | 1,400 | Zinc-Plated Steel | 10 | 000000000 | 0000 | 0.385" | 0.052" | 10 | 000000000 | 0000 |

1/4" Dia. | ||||||||||||||||

| 0.063"-0.625" | 2" | 0.265" | K | 0.525" | 0.152" | 2,200 | 2,550 | Zinc-Plated Steel | 10 | 000000000 | 0000 | 0.525" | 0.07" | 10 | 000000000 | 0000 |

| 0.313"-1.25" | 2.625" | 0.265" | K | 0.525" | 0.152" | 2,200 | 2,550 | Zinc-Plated Steel | 10 | 000000000 | 0000 | 0.525" | 0.07" | 10 | 000000000 | 0000 |

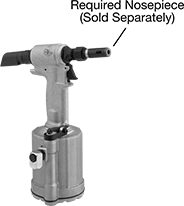

Air Inlet | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pull Capacity, lbs. | Stroke Lg. | Operating Air Pressure, psi | Average Air Consumption, cfm | Pipe Size | Gender | Air Hose Included | Each | |

| 5,200 | 5/8" | 90-100 | 1.5 | 1/4 | Female | No | 000000000 | 000000000 |