Hand Vises for Irregularly Shaped Material

Arrange the pins in a series of holes to grip parts with angled or uneven sides. Turn the thumbscrew to adjust the jaws.

Jaw | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Max. Dia. | Wd. | Material | Texture | Throat Dp. | Lg. | Ht. | Body Material | No. of Pins | Each | |

| 2 1/4" | 1 7/8" | Aluminum | Smooth | 3/8" | 5 1/4" | 3 1/8" | Wood | 8 | 0000000 | 000000 |

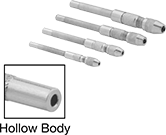

Hollow-Body Pin Vise Sets

Set includes four vises with different opening sizes. Pass wires and rods through the hollow body; turn the collar to close the collet around the material.

Jaw | Overall | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Opening | Min. Opening | Material | Texture | Dia. | Lg. | Body Material | Container Type | Each | |

| 0.055" 0.075" 0.125" 0.187" | 0" 0.025" 0.045" 0.11" | Steel | Serrated | 5/16" 3/8" 7/16" 9/16" | 3 1/8" 3 1/2" 3 13/16" 4" | Steel | Plastic Pouch | 0000000 | 000000 |

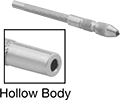

Hollow-Body Pin Vises

Pass wires and rods through the hollow body of these vises. Turn the collar to close the collet around the material.

Quick-Clamping Hollow-Body Pin Vises

Clamp and unclamp with one hand by sliding the knurled ring forward to close the collet. Wires and rods can pass through the hollow body.

Jaw | Overall | ||||||

|---|---|---|---|---|---|---|---|

| Max. Opening | Material | Texture | Dia. | Lg. | Body Material | Each | |

| 0.051" | Steel | Smooth | 5/16" | 4 1/8" | Aluminum | 0000000 | 000000 |

Two-Tip Hollow-Body Pin Vises

Each end of the vise has a collet to hold a different tool—turn the collar to close the collets around them. Wires and rods can pass through the hollow body.

Jaw | Overall | ||||||

|---|---|---|---|---|---|---|---|

| Max. Opening | Material | Texture | Dia. | Lg. | Body Material | Each | |

| 0.013", 0.125" | Steel | Serrated | 7/16" | 3 5/8" | Steel | 0000000 | 000000 |

Precise-Control Pin Vises

Press the rotating end cap on the handle with your palm to apply constant pressure while turning the body of the vise with your fingertips. Turn the collar to close the collet around the material.

Jaw | Overall | ||||||

|---|---|---|---|---|---|---|---|

| Max. Opening | Material | Texture | Dia. | Lg. | Body Material | Each | |

| 0.125" | Steel | Serrated | 3/8" | 3 3/4" | Aluminum | 0000000 | 000000 |

Cushion-Grip Precise-Control Pin Vises

A rubber-covered body provides a comfortable grip. Press the rotating end cap on the handle with your palm to apply constant pressure while turning the body of the vise with your fingertips. Turn the collar to close the collet around the material.

Jaw | Overall | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max. Opening | Material | Texture | Dia. | Lg. | Body Material | Grip Material | Features | Each | |

| 0.125" | Steel | Smooth | 7/8" | 4 1/4" | Plastic | Rubber | Drill and Tap Storage in Body | 000000 | 000000 |

Hand Vises

These vises have flat jaws.

Styles A and C adjust by turning the wingnut.

Style B adjusts by turning the handle.

Vises with hollow body allow wires and rods to pass through.

Jaw | Overall | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Wd. | Max. Opening | Material | Texture | Throat Dp. | Lg. | Ht. | Body Material | Features | Each | |

| A | 1/4" | 0.25" | Steel | Serrated | 1/2" | 4 1/2" | 1 1/8" | Steel | Hollow Body | 0000000 | 000000 |

| A | 5/8" | 0.25" | Steel | Serrated | 1/2" | 4 1/2" | 1" | Steel | Hollow Body | 0000000 | 00000 |

| B | 1/2" | 0.5" | Steel | Serrated | 1/2" | 4 3/4" | 1 1/2" | Steel | Hollow Body | 0000000 | 00000 |

| C | 1 1/4" | 1" | Steel | Grooved | 1/2" | 6 1/4" | 3" | Wood | __ | 0000000 | 00000 |

Squeeze-to-Open Hand Vises

Squeeze the body to open the flat jaws; release to grip.

Jaw | Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Lg. | Wd. | Max. Opening | Material | Texture | Lg. | Ht. | Body Material | Each | |

Rectangular Jaws | ||||||||||

| __ | 7/16" | 3/16" | 0.75" | Stainless Steel | Smooth | 2 1/4" | 1" | 303 Stainless Steel | 0000000 | 000000 |

| __ | 1/2" | 1/8" | 0.75" | Stainless Steel and Rubber | Smooth | 2 1/4" | 1" | 303 Stainless Steel | 0000000 | 00000 |

| __ | 11/16" | 1/8" | 0.75" | Stainless Steel | Smooth | 2 3/4" | 1" | 303 Stainless Steel | 0000000 | 00000 |

Round Jaws | ||||||||||

| 1/4" | __ | __ | 0.625" | Brass and Rubber | Serrated | 2 1/4" | 7/8" | 303 Stainless Steel | 0000000 | 00000 |

| 1/4" | __ | __ | 0.625" | Rubber | Serrated | 2 1/4" | 7/8" | 303 Stainless Steel | 0000000 | 00000 |

Hand Vises for Round Material

Notches on the jaws hold round material on its outside diameter. Each set of notches holds a different diameter. Turn the thumbscrew to adjust the jaws.

Jaw | Overall | |||||||

|---|---|---|---|---|---|---|---|---|

| For Dia. | Wd. | Material | Texture | Lg. | Ht. | Body Material | Each | |

| 1/2"-1 3/8" | 1 1/4" | Brass | Smooth | 1 7/8" | 1" | Brass | 0000000 | 000000 |

Collet Fixtures

Pair these fixtures with collets to tightly grip workpieces for machining. You can mount them on milling machines, drill presses, and other work surfaces. However, they’re not for use with lathes, grinders, or high-speed rotary tables. All have a through hole to accommodate long workpieces.

Lever fixtures have a handle that can be indexed to any position—no tools required. They’re often used for quickly swapping workpieces in and out, when a simple clamping mechanism is more important than consistent holding force. These fixtures keep the collet stationary while their sleeve clamps. Made from cast iron, they dampen vibration better than steel fixtures, though they’re less durable.

Collet nut fixtures convert ER collets—typically used to hold tool bits—into holders for cylindrical workpieces. The tapered, slit design of the collet distributes clamping force evenly around a workpiece. This creates a stable, consistent grip that keeps your workpiece from shifting, even under 5-axis machining forces. These fixtures are made of steel to withstand the high clamping forces and frequent cycles of production environments.

Square-drive fixtures are designed for precise, repeatable workholding with consistent clamping force. They keep the collet stationary while their sleeve clamps. Made of steel, these fixtures are stronger and more wear resistant than cast iron fixtures, and they can hold up to higher clamping forces. They’re precision machined for accuracy. Use the included socket wrench to clamp and unclamp your workpiece or use a calibrated torque wrench to fine-tune the clamping force.

Mounting Slots | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Lg. | Wd. | Ht. | Material | No. of | Wd. | Mounting Orientation | Power Source | Each | |

| 5C | 1 1/16" | 1 1/16" | 3 3/4" | 5" | 4" | Enamel-Coated Cast Iron | 4 | 11/16" | Horizontal, Vertical | Manual | 0000000 | 0000000 |

Mounting Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Orientation | Power Source | Each | |

| ER-16 | 3/8" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 0000000 |

| ER-20 | 1/2" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-25 | 5/8" | 7/16" | 2 3/4" | 2 1/2" | Black-Oxide Steel | 4 | 1/4" | 2 1/8" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-25 | 5/8" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-32 | 13/16" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 |

| ER-40 | 1" | 11/16" | 5" | 3" | Black-Oxide Steel | 4 | 7/16" | 4" | Horizontal, Vertical | Manual | 0000000 | 000000 |

Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Collet Type | For Max. Workpiece Dia. | Through Hole Dia. | Dia. | Ht. | Material | No. of | Dia. | Bolt Circle Dia. | Mounting Orientation | Power Source | Includes | Each | |

| 5C | 1 1/16" | 1 3/16" | 5" | 3 1/2" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 000000000 |

| 16C | 1 5/8" | 1 13/16" | 5" | 4 1/2" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 00000000 |

| 3J | 1 3/4" | 1 15/16" | 5" | 4" | Black-Oxide Steel | 6 | 3/8" | 4 1/8" | Horizontal, Vertical | Manual | Socket Wrench | 0000000 | 00000000 |

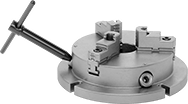

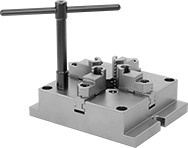

Stationary Jaw Clamping Fixtures

Mount these fixtures to a milling machine, drill press, or other flat surface and use the jaws to grip workpieces. Their low-profile design maximizes tool clearance, which helps you machine efficiently. The jaws are precision ground to tight tolerances for repeatable centering that’s accurate within 0.02 mm. These fixtures are self-centering—they use scroll actuation, which means that all jaws move in unison to center the workpiece as they close.

Each fixture comes with reversible jaws, which you can install for either an inside or outside grip. Use the included wrench to open or close the jaws.

Fixtures with three jaws are best for gripping round workpieces. Fixtures with four jaws have more holding power than those with three jaws, so they’re often used on square or rectangular workpieces.

For Workpiece | Base | Mounting Slots | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | ID | Dia. | Ht. | Dia | Ht. | Center Through-Hole Dia. | Material | No. of | Wd. | Includes | Each | |

| 5/16"-6 5/16" (8-160 mm) | 1 7/8"- 5 29/32" (48-150 mm) | 6 11/16" (170 mm) | 1 9/16" (40 mm) | 8 21/32" (220 mm) | 11/16" (18 mm) | 1 25/32" (45 mm) | Steel | 4 | 1/2" (13 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 000000000 |

| 7/16"-7 7/8" (11-200 mm) | 2 7/16"- 7 1/2" (62-190 mm) | 8 1/4" (210 mm) | 1 25/32" (45 mm) | 10 5/8" (270 mm) | 25/32" (20 mm) | 2 3/8" (60 mm) | Steel | 4 | 1/2" (13 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 15/32"-9 27/32" (12-250 mm) | 2 27/32"- 9 7/16" (72-240 mm) | 10 1/32" (255 mm) | 2 3/32" (53 mm) | 12 13/32" (315 mm) | 25/32" (20 mm) | 3 5/32" (80 mm) | Steel | 4 | 5/8" (16 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 19/32"-11 13/16" (15-300 mm) | 3 3/8"- 11 13/32" (86-290 mm) | 12" (305 mm) | 2 9/32" (58 mm) | 14 9/16" (370 mm) | 7/8" (22 mm) | 4 1/8" (105 mm) | Steel | 4 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

For Workpiece | Base | Mounting Slots | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | ID | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Center Through-Hole Dia. | Material | No. of | Wd. | Includes | Each | |

| 5/32"-5 1/32" (4-128 mm) | 2 5/32"- 5 1/32" (55-128 mm) | 6 1/2" (165 mm) | 6 1/2" (165 mm) | 1 17/32" (39 mm) | 8 15/32" (215 mm) | 6 1/2" (165 mm) | 11/16" (18 mm) | 1 19/32" (40 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 000000000 |

| 3/16"-6 3/8" (5-162 mm) | 2 7/16"- 6 3/8" (62-162 mm) | 7 7/8" (200 mm) | 7 7/8" (200 mm) | 1 25/32" (45 mm) | 9 27/32" (250 mm) | 7 7/8" (200 mm) | 25/32" (20 mm) | 2 5/32" (55 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 1/4"-7 7/8" (6-200 mm) | 2 27/32"- 7 7/8" (72-200 mm) | 9 27/32" (250 mm) | 9 27/32" (250 mm) | 1 31/32" (50 mm) | 12 7/32" (310 mm) | 9 27/32" (250 mm) | 7/8" (22 mm) | 2 3/4" (70 mm) | Steel | 2 | 11/16" (18 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |

| 13/32"-10 7/16" (10-265 mm) | 3 9/16"- 10 7/16" (90-265 mm) | 12 7/32" (310 mm) | 12 7/32" (310 mm) | 2 3/8" (60 mm) | 14 31/32" (380 mm) | 12 7/32" (310 mm) | 1" (25 mm) | 3 15/16" (100 mm) | Steel | 2 | 7/8" (22 mm) | One Set of Hardened Reversible Jaws, One Chuck Wrench | 0000000 | 00000000 |