Filter by

Mount Type

Tank Circulation Rate @ Pressure

Inlet Flow Rate @ Pressure

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Temperature Setting

Round-Platform Vibrating Tables

|  |

5 lb. Capacity | 12 lb. Capacity |

Platform | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Ht. | Wd. | Dp. | Current, amp | Freq., Hz | Dia. | Material | Vibration Freq., vpm | Duty Cycle | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase—3-Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 4 1/2" | 4 1/2" | 4 1/2" | 2.5 | 60 | 4" | Rubber-Coated Zinc | 3,600 | 15 Minutes On, 5 Minutes Off | Variable-Speed Control | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 6 1/2" | 11" | 4 1/2" | 2 | 60 | 6" | Rubber-Coated Zinc | 3,600 | 15 Minutes On, 5 Minutes Off | Variable-Speed Control | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular-Platform Vibrating Tables

|  |

8 lb. Capacity | 10 lb. Capacity |

Platform | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Ht. | Wd. | Dp. | Current, amp | Freq., Hz | Wd. | Dp. | Material | Vibration Freq., vpm | Duty Cycle | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC, Single Phase—3-Blade Plug | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4 1/2" | 10 1/2" | 7 1/2" | 3 | 60 | 10 1/2" | 7 1/2" | Rubber-Coated Steel | 3,600 | 15 Minutes On, 5 Minutes Off | Variable-Speed Control | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5 15/16" | 10" | 7" | 1 | 60 | 10" | 7" | Plastic | 3,600 | 15 Minutes On, 5 Minutes Off | Variable-Speed Control | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

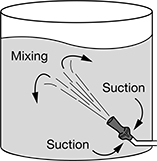

Tank Mixing Nozzles

Orifice Dia. | Pipe Size | Thread Type | Gender | Inlet Flow Rate @ Pressure | Tank Circulation Rate @ Pressure | Dia. | Lg. | Max. Pressure @ Temp. | Max. Temp., ° F | Material | Color | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.06" | 1/4 | NPT | Male | 0.7 gpm @ 50 psi | 4.4 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Orange | 0000000 | 000000 | |

| 0.08" | 1/4 | NPT | Male | 1.2 gpm @ 50 psi | 6 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Green | 0000000 | 00000 | |

| 0.1" | 1/4 | NPT | Male | 2 gpm @ 50 psi | 7.8 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | Blue | 0000000 | 00000 | |

| 0.12" | 1/4 | NPT | Male | 2.9 gpm @ 50 psi | 10.7 gpm @ 50 psi | 11/16" | 1 5/8" | 50 psi @ 70° F | 200 | Polypropylene | White | 0000000 | 00000 | |

| 3/16" | 1/4 | NPT | Male | 7.8 gpm @ 50 psi | 36.8 gpm @ 50 psi | 1 1/4" | 3" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 5/16" | 3/8 | NPT | Male | 20 gpm @ 50 psi | 100 gpm @ 50 psi | 1 11/16" | 4 1/16" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 3/8" | 3/4 | NPT | Male | 30 gpm @ 50 psi | 150 gpm @ 50 psi | 3" | 6 3/8" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 00000 | |

| 9/16" | 1 1/2 | NPT | Male | 75 gpm @ 50 psi | 375 gpm @ 50 psi | 4 1/2" | 10" | 50 psi @ 70° F | 200 | Polypropylene | Black | 0000000 | 000000 |

Stirring Hot Plates for Glass Containers

Heating Surface | Temp., ° C | Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Wd. | Dp. | Material | Wt. Cap., lb. | Setting | Adjustment Increment | Ht. | Wd. | Dp. | Housing Material | Wattage, W | Temp. Control Type | No. of Blades | Electrical Connection | NEMA Type | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

120V AC—Plug In | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 7" | 7" | Ceramic | 40 | 5 to 550 | 0.5 | 4 9/16" | 8 11/16" | 12 15/16" | Aluminum | 1,582 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10" | 10" | Ceramic | 45 | 5 to 500 | 0.5 | 4 5/8" | 11 9/32" | 15 13/16" | Aluminum | 1,650 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 5/16" | — | — | Ceramic-Coated Aluminum | 40 | 5 to 360 | 0.5 | 4 1/2" | 6 7/8" | 10 3/16" | Aluminum | 600 | Dial | 3 | Straight Blade | 5-15 | TUV Rheinland Certified | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||