Filter by

Movement

Base Material

Ring Material

Inner Ring Width

Ring Thickness

Weight Capacity

Ring Height

Load Securement Type

Material

Base Width

Base Length

Ring Finish

Finish

Export Control Classification Number (ECCN)

DFARS Specialty Metals

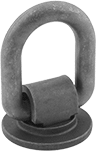

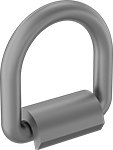

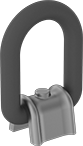

Weld-On Tie-Down Rings

|  |  |  |

Style A | Style B | Style C | Style D |

Ring | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Ht. | Thk. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2,000 | 2 9/16" | 2 11/16" | 3/8" | D-Ring | 2" | 15/16" | — | 1/4" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,600 | 1 1/2" | 3 3/16" | 1/2" | D-Ring | 1 3/8" | 1 15/16" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11,000 | 1 3/4" | 3 7/16" | 9/16" | D-Ring | 1 5/8" | 1 15/16" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 17,600 | 2" | 4 1/16" | 11/16" | D-Ring | 1 13/16" | 2 3/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 29,800 | 2 11/16" | 5 11/16" | 15/16" | D-Ring | 2 1/2" | 3 1/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 44,100 | 2 3/4" | 6" | 1 1/16" | D-Ring | 2 1/2" | 3 5/8" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 17,600 | 1 7/8" | 3 3/8" | 9/16" | D-Ring | 5 1/4" | 2 5/8" | 1 1/16" | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 29,800 | 2 3/8" | 4 1/16" | 13/16" | D-Ring | 6 11/16" | 3 1/8" | 1 7/16" | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2,100 | 1 7/16" | 2 9/16" | 0.43" | D-Ring | 1 1/4" | 1 1/4" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3,500 | 1 5/8" | 3 1/16" | 0.55" | D-Ring | 1 1/2" | 1 1/2" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 7,100 | 1 7/8" | 3 3/4" | 0.71" | D-Ring | 1 3/4" | 1 3/4" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 12,000 | 2 5/8" | 5 3/8" | 0.94" | D-Ring | 2 3/8" | 2 3/8" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 18,100 | 2 13/16" | 5 3/4" | 1.1" | D-Ring | 2 11/16" | 2 9/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 34,200 | 4 3/4" | 8 1/8" | 1 1/2" | D-Ring | 3 3/4" | 4 1/4" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,080 | 2 3/8" | 3 1/2" | 1/2" | D-Ring | 2" | 1 5/16" | — | 11/16" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,080 | 2 1/2" | 5 1/2" | 1/2" | D-Ring | 2" | 1 5/16" | — | 3/8" | Low-Carbon Steel | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,130 | 3" | 4 1/4" | 5/8" | D-Ring | 2 1/2" | 1 5/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9,120 | 3" | 4 1/2" | 3/4" | D-Ring | 2 1/4" | 1 5/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 15,500 | 3" | 6" | 1" | D-Ring | 2 1/4" | 2 1/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 15,500 | 3" | 5 1/2" | 1" | Angled-Bend D-Ring | 2 1/4" | 2 1/8" | — | 1/2" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3,000 | 2 5/16" | 3 5/8" | 1/2" | D-Ring | 2" | 1 3/8" | — | 1/4" | 316 Stainless Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,500 | 2 15/16" | 4 1/2" | 5/8" | D-Ring | 2 9/16" | 1 3/4" | — | 3/8" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,500 | 2 15/16" | 4 5/8" | 3/4" | D-Ring | 2 9/16" | 1 7/8" | — | 3/8" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 8,500 | 3" | 5 1/8" | 1" | D-Ring | 2 9/16" | 2 1/8" | — | 1/2" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Weld-On Tie-Down Rings

Ring | Base | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap. | Inner Wd. | Ht. | Thk. | Style | Dia. | Lg. | Wd. | Material | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1/4" | 3/4" | 3/16" | Round Ring | 5/8" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/8" | 1" | 1/4" | Round Ring | 7/8" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 5/8" | 1 5/16" | 1/4" | Round Ring | 1" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/4" | 1 5/8" | 3/8" | Round Ring | 1 1/16" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1" | 2 5/16" | 9/16" | Round Ring | 1 7/16" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 3/16" | 2 3/8" | 7/16" | Round Ring | 1 11/16" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/4" | 2 3/4" | 11/16" | Round Ring | 1 3/4" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Not Rated | 5/8" | 7/8" | 1/4" | Round Ring | — | 1 1/8" | 1 1/8" | Alloy Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1/2" | 1 1/16" | 3/16" | Round Ring | 3/8" | — | — | 316 Stainless Steel | 000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 5/8" | 1 5/16" | 1/4" | Round Ring | 9/16" | — | — | 316 Stainless Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/4" | 1 9/16" | 5/16" | Round Ring | 5/8" | — | — | 316 Stainless Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1" | 2" | 3/8" | Round Ring | 7/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/4" | 2 1/2" | 1/2" | Round Ring | 1" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/2" | 3 1/4" | 5/8" | Round Ring | 1 3/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swiveling Weld-On Tie-Down Rings

Tie-Down Rings

|  |  |

Style A | Style B | Style E |

Ring | Base | Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Material | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. Lg. | For Mounting Screw Size | 1-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1,000 | 1 7/16" | 1 1/2" | 1/4" | D-Ring | 1 5/8" | 1 3/8" | Zinc-Plated Steel | No | 1 | 7/16" | — | 7/16" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1,000 | 1 1/2" | 1 13/16" | 1/4" | D-Ring | 1 9/16" | 1 1/4" | Zinc-Plated Steel | No | 2 | 1/4" | 15/16" | 1/4" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1,500 | 2" | 2 1/8" | 1/4" | D-Ring | 2 1/8" | 1 7/8" | Zinc-Plated Steel | No | 2 | 1/4" | 1 3/8" | 1/4" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 800 | 1 29/32" | 2 1/8" | 1/4" | D-Ring | 1 9/16" | 1 1/2" | Zinc-Plated Steel | No | 1 | 13/32" | — | 3/8" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesive-Ready Tie-Down Rings

Ring | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Thk. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not Rated | 1/2" | 13/16" | 3/16" | Angled-Bend D-Ring | 1 1/4" | 1 1/4" | 1/16" | 316 Stainless Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimpled Tie-Down Rings

Ring | Base | Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Material | Mounting Fasteners Included | No. of | Dia. | 1-49 | 50-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5,600 | 1 1/8" | 1 3/16" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | Zinc-Plated Steel | No | 1 | 7/16" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5,620 | 1 1/8" | 1 3/16" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | 316 Stainless Steel | No | 1 | 7/16" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5,620 | 1 1/8" | 1 3/16" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | 316 Stainless Steel | No | 1 | 7/16" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tie-Down Rings for Quick-Adjust L-Tracks

|  |

Round Rings for 1 Mounting Point |

Wt. Cap., lb. | Inner Ring Wd. | Projection | End Fitting Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Round Rings for 1 Mounting Point | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,000 | 1 1/2" | 2" | Zinc-Plated Steel | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||