Filter by

Attachment Type

Material

Application

Length

Weight Capacity

Eye ID

Clevis Inside Width

Wire Rope Construction

Export Control Classification Number (ECCN)

DFARS Specialty Metals

End Fitting Type

Specifications Met

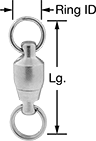

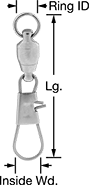

Split Ring-to-Split Ring Miniature Ball Bearing Swivels—Not for Lifting

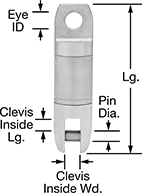

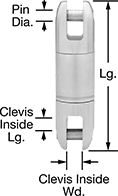

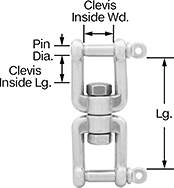

Clevis-to-Clevis Ball Bearing Swivels—For Lifting

|

Clevis | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Inside Wd. | Inside Lg. | Pin Dia. | Wt. Cap., lb. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 11/32" | 5/16" | 15/32" | 5/16" | 1,000 | ASME B30.26 | 33575T651 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 19/32" | 11/16" | 3/8" | 1,500 | ASME B30.26 | 33575T652 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 9/16" | 19/32" | 13/16" | 7/16" | 3,000 | ASME B30.26 | 33575T653 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 5/32" | 3/4" | 15/16" | 5/8" | 6,000 | ASME B30.26 | 33575T654 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 1/2" | 1" | 1 9/16" | 7/8" | 10,000 | ASME B30.26 | 33575T655 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 19/32" | 11/16" | 3/8" | 1,500 | ASME B30.26 | 33575T501 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 29/32" | 19/32" | 13/16" | 7/16" | 3,000 | ASME B30.26 | 33575T502 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/2" | 3/4" | 15/16" | 5/8" | 6,000 | ASME B30.26 | 33575T503 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 1" | 1 9/16" | 7/8" | 10,000 | ASME B30.26 | 33575T504 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Eye-to-Clevis Ball Bearing Swivels—Not for Lifting

|

Eye | Clevis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | ID | Inside Wd. | Pin Dia. | Wt. Cap., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 13/16" | 1/4" | 5/16" | 3/8" | 1/4" | 1,800 | 8928T33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

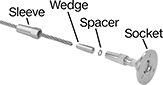

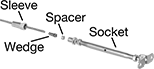

Mounting-Plate-End Sleeve-Grip Wire Rope End Fittings—Not for Lifting

For Wire Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Overall Lg. | Sleeve Dia. | Max. Pivot Angle | No. of Mounting Holes | For Screw Size | Mounting Fasteners Included | Rope Cap. Adjustment Factor | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swiveling End | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/4" | 13/32" | 45° | 3 | No. 8 | Yes | 80% | 9161T2 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

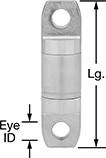

Eye-to-Eye Ball Bearing Swivels—Not for Lifting

|

Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | ID | Wt. Cap., lb. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 1/4" | 5/16" | 1,100 | 8928T41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

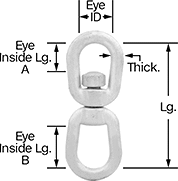

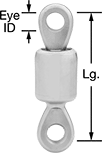

Eye-to-Eye Swivels—Not for Lifting

Eye | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | Inside Lg. (A) | Inside Lg. (B) | ID | Wt. Cap., lb. | Fabrication | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1/4" | 3/4" | 1" | 3/4" | 800 | Forged | — | 3552T141 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 5/8" | 5/16" | 3/4" | 1 1/4" | 1" | 1,200 | Forged | Fed. Spec. RR-C-271 | 3552T15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 5/16" | 3/8" | 7/8" | 1 1/2" | 1 1/4" | 2,200 | Forged | Fed. Spec. RR-C-271 | 3552T16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/8" | 1/2" | 1 3/16" | 2" | 1 1/2" | 3,600 | Forged | Fed. Spec. RR-C-271 | 3552T17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 5/8" | 5/8" | 1 1/2" | 2 3/8" | 1 3/4" | 5,200 | Forged | Fed. Spec. RR-C-271 | 3552T18 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 3/8" | 3/4" | 1 5/8" | 2 5/8" | 2" | 7,000 | Forged | Fed. Spec. RR-C-271 | 3552T19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 3/16" | 9/16" | 9/16" | 1/2" | 300 | Cast | — | 3714T91 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 1/4" | 5/8" | 5/8" | 9/16" | 600 | Cast | — | 3714T92 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/16" | 5/16" | 7/8" | 7/8" | 3/4" | 1,000 | Cast | — | 3714T93 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 3/8" | 7/8" | 7/8" | 15/16" | 1,900 | Cast | — | 3714T94 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 1/2" | 1 3/8" | 1 3/8" | 1 5/16" | 2,700 | Cast | — | 3714T95 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/16" | 5/8" | 1 3/4" | 1 3/4" | 1 1/2" | 4,600 | Cast | — | 3714T96 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

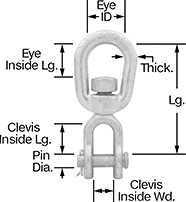

Eye-to-Clevis Swivels—Not for Lifting

Eye | Clevis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | Inside Lg. | ID | Inside Wd. | Inside Lg. | Pin Dia. | Pin Type | Wt. Cap., lb. | Fabrication | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 5/16" | 3/4" | 1" | 1/2" | 13/16" | 5/16" | Cotter | 1,200 | Forged | Fed. Spec. RR-C-271 | 3553T15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 3/8" | 7/8" | 1 1/4" | 5/8" | 1 1/16" | 3/8" | Cotter | 2,200 | Forged | Fed. Spec. RR-C-271 | 3553T16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 9/16" | 1/2" | 1 1/4" | 1 1/2" | 7/8" | 1 7/16" | 1/2" | Cotter | 3,600 | Forged | Fed. Spec. RR-C-271 | 3553T17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2" | 5/8" | 1 9/16" | 1 3/4" | 1" | 1 1/2" | 5/8" | Cotter | 5,200 | Forged | Fed. Spec. RR-C-271 | 3553T18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 3/4" | 1 3/4" | 2" | 1 1/8" | 1 3/4" | 3/4" | Cotter | 7,000 | Forged | Fed. Spec. RR-C-271 | 3553T19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1/4" | 9/16" | 5/8" | 1/2" | 7/16" | 7/32" | Screw | 600 | Cast | — | 30365T31 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 11/16" | 5/16" | 13/16" | 13/16" | 23/32" | 5/8" | 5/16" | Screw | 1,000 | Cast | — | 30365T32 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 5/8" | 3/8" | 1 1/16" | 15/16" | 13/16" | 15/16" | 3/8" | Screw | 1,900 | Cast | — | 30365T33 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 5/8" | 1/2" | 1 3/8" | 1 3/16" | 15/16" | 1 1/8" | 1/2" | Screw | 2,700 | Cast | — | 30365T34 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 3/4" | 5/8" | 1 3/4" | 1 1/2" | 1 1/4" | 1 1/2" | 5/8" | Screw | 4,600 | Cast | — | 30365T35 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 13/16" | 3/4" | 2" | 1 5/8" | 1 23/32" | 1 11/16" | 25/32" | Screw | 5,500 | Cast | — | 30365T36 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

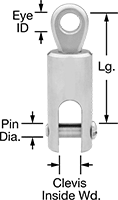

Eye-to-Clevis Ball Bearing Swivels—For Lifting

Eye | Clevis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thk. | ID | Inside Wd. | Inside Lg. | Pin Dia. | Wt. Cap., lb. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 1/4" | 1/4" | 5/16" | 5/16" | 5/16" | 1,000 | ASME B30.26 | 33575T1 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 9/16" | 5/16" | 3/8" | 3/8" | 1/2" | 3/8" | 1,500 | ASME B30.26 | 33575T2 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 9/16" | 1/2" | 5/8" | 7/16" | 23/32" | 7/16" | 3,000 | ASME B30.26 | 33575T3 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 1/8" | 3/4" | 7/8" | 3/4" | 15/16" | 5/8" | 6,000 | ASME B30.26 | 33575T4 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 1/2" | 1" | 1 1/4" | 1" | 1 1/8" | 7/8" | 10,000 | ASME B30.26 | 33575T5 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

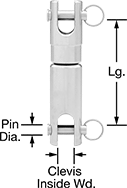

Clevis-to-Clevis Swivels—Not for Lifting

|

Clevis | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Inside Wd. | Inside Lg. | Pin Dia. | Wt. Cap., lb. | Fabrication | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot-Dipped Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 3/8" | 3/8" | 3/16" | 450 | Forged | 37405T32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 15/16" | 1/2" | 1/2" | 1/4" | 750 | Forged | 37405T33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 11/16" | 11/16" | 11/16" | 5/16" | 1,200 | Forged | 37405T34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/8" | 3/4" | 1" | 3/8" | 2,000 | Forged | 37405T35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/32" | 1" | 1 1/4" | 1/2" | 3,500 | Forged | 37405T36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 11/32" | 1 1/4" | 1 1/2" | 5/8" | 5,000 | Forged | 37405T37 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/2" | 1 5/8" | 1 3/4" | 3/4" | 7,000 | Forged | 37405T38 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 7/16" | 3/8" | 3/16" | 300 | Cast | 37405T31 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 7/8" | 1/2" | 7/16" | 1/4" | 600 | Cast | 37405T24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 17/32" | 5/8" | 5/8" | 5/16" | 1,100 | Cast | 37405T25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/16" | 3/4" | 13/16" | 3/8" | 1,500 | Cast | 37405T26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 5/16" | 1" | 15/16" | 1/2" | 2,600 | Cast | 37405T27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 7/16" | 1 1/4" | 1 3/8" | 5/8" | 4,700 | Cast | 37405T28 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 7/32" | 1 1/2" | 1 1/2" | 3/4" | 7,100 | Cast | 37405T29 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

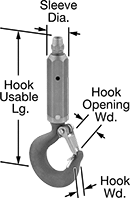

Extra-Flexible Wire Rope with Hook

Hook | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Wt. Cap., lb. | Wire Rope Construction | Recommended Pulley/Drum Dia. | Opening Wd. | Usable Lg. | Preformed | Specifications Met | 5 ft. Long | 10 ft. Long | 15 ft. Long | 20 ft. Long | 25 ft. Long | 30 ft. Long | 40 ft. Long | 50 ft. Long | 75 ft. Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1,400 | 7 × 19 Strand Core | 6 1/2" | 7/8" | 4 9/16" | Yes | Fed. Spec. RR-W-410 | 2261N14 | 000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clevis-to-Clevis Ball Bearing Swivels—Not for Lifting

Eye-to-Eye Ball Bearing Swivels—For Lifting

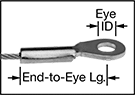

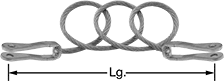

Eye-to-Swivel-Fork Lanyards—Not for Lifting

|  | |

Eye | Swivel Fork | Uncoated | Clear Nylon Coated | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wt. Cap., lb. | End-to-Eye Lg. | Thk. | ID | For Screw Size | Material | Lg. | Inside Wd. | For Pin Dia. | For Pin Usable Lg. | Material | Each | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/16" Diameter—7 × 7 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 100 | 1" | 39/64" | 13/64" | No. 10 | 18-8 Stainless Steel | 1 1/16" | 3/32" | 3/16" | 1/4" | 18-8 Stainless Steel | 30345T233 | 000000 | -40 to 200 | 30345T232 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 100 | 1" | 39/64" | 13/64" | No. 10 | 18-8 Stainless Steel | 1 1/16" | 3/32" | 3/16" | 1/4" | 18-8 Stainless Steel | 30345T236 | 00000 | -40 to 200 | 30345T235 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 100 | 1" | 39/64" | 13/64" | No. 10 | 18-8 Stainless Steel | 1 1/16" | 3/32" | 3/16" | 1/4" | 18-8 Stainless Steel | 30345T239 | 00000 | -40 to 200 | 30345T238 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 100 | 1" | 39/64" | 13/64" | No. 10 | 18-8 Stainless Steel | 1 1/16" | 3/32" | 3/16" | 1/4" | 18-8 Stainless Steel | 30345T243 | 00000 | -40 to 200 | 30345T242 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 100 | 1" | 39/64" | 13/64" | No. 10 | 18-8 Stainless Steel | 1 1/16" | 3/32" | 3/16" | 1/4" | 18-8 Stainless Steel | 30345T246 | 00000 | -40 to 200 | 30345T245 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Closed-Body Mounting-Plate-to-Wire Rope Turnbuckles—Not for Lifting

316 Stainless Steel Body with 316 Stainless Steel End Fitting

Mounting Plate | For Wire Rope | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Rope Cap. Adjustment Factor | Retracted Lg. | Max. Adjustment | Extended Lg. | Lg. | Wd. | Movement | Thread Size | Dia. | Construction | Wire Rope Fitting Type | No. of Mounting Holes | Mounting Hole Dia. | Mounting Fasteners Included | Each | |||

| 70% | 4 1/16" | 1 3/8" | 5 7/16" | 1 1/2" | 1 1/2" | 360° Swivel | 1/4"-28 | 5/32" | 1 × 19 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 3 | 0.164" | Yes | 9161T1 | 000000 | ||

| 70% | 6 7/8" | 2 1/2" | 9 3/8" | 2 1/8" | 5/8" | 360° Swivel | 1/4"-28 | 1/8" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 2 | 0.244" | Yes | 9161T41 | 00000 | ||

| 70% | 7 3/4" | 3" | 10 3/4" | 2 13/16" | 13/16" | 360° Swivel | 5/16"-24 | 3/16" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 2 | 0.318" | Yes | 9161T42 | 00000 | ||

| 70% | 9" | 3 7/16" | 12 7/16" | 3 1/16" | 7/8" | 360° Swivel | 3/8"-24 | 1/4" | 1 × 19 Strand Core 7 × 7 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Sleeve Grip | 2 | 0.394" | Yes | 9161T43 | 000000 | ||

Split Ring-to-Snap Miniature Ball Bearing Swivels—Not for Lifting

|

Lg. | Ring ID | Snap Inside Wd. | Wt. Cap., lb. | Bearing Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nickel-Plated Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/8" | 1/8" | 10 | 18-8 Stainless Steel | 3179T6 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/16" | 3/16" | 1/4" | 10 | 18-8 Stainless Steel | 3179T7 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 9/16" | 1/4" | 1/4" | 30 | 18-8 Stainless Steel | 3179T8 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1/4" | 5/16" | 50 | 18-8 Stainless Steel | 3179T9 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/16" | 5/16" | 7/16" | 70 | 18-8 Stainless Steel | 3179T11 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

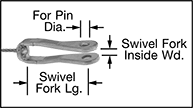

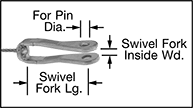

Swivel-Fork-to-Swivel-Fork Retractable Lanyards—Not for Lifting

|  |

Swivel Fork | Clear Vinyl Plastic Coated | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended Lg. | Retracted Lg. | Wt. Cap., lb. | Lg. | Inside Wd. | For Pin Dia. | For Pin Usable Lg. | Material | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Galvanized Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/16" Diameter—7 × 7 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 6" | 100 | 1 1/16" | 3/32" | 3/16" | 3/16" | 18-8 Stainless Steel | -40 to 170 | 90312A242 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18" | 6 1/4" | 100 | 1 1/16" | 3/32" | 3/16" | 3/16" | 18-8 Stainless Steel | -40 to 170 | 90312A245 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 6 1/2" | 100 | 1 1/16" | 3/32" | 3/16" | 3/16" | 18-8 Stainless Steel | -40 to 170 | 90312A248 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 ft. | 7" | 100 | 1 1/16" | 3/32" | 3/16" | 3/16" | 18-8 Stainless Steel | -40 to 170 | 90312A252 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 ft. | 7 1/2" | 100 | 1 1/16" | 3/32" | 3/16" | 3/16" | 18-8 Stainless Steel | -40 to 170 | 90312A255 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

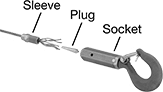

Swivel-Hook-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Hook | Steel | Zinc-Plated Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Sleeve Dia. | Usable Lg. | Opening Wd. | Wd. | Fabrication | Material | Wt. Cap., lb. | Specs. Met | Each | Each | |||

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3/4" | 5 31/32" | 1" | 9/16" | Forged | Steel | 665 | ASME B30.26 | 1757N11 | 0000000 | 1757N15 | 0000000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 6 27/32" | 1 1/16" | 5/8" | Forged | Steel | 1,175 | ASME B30.26 | ——— | 0 | 1757N16 | 000000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 7 7/16" | 1 1/16" | 5/8" | Forged | Steel | 1,175 | ASME B30.26 | 1757N12 | 000000 | ——— | 0 | |

| 5/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 7 19/32" | 1 1/8" | 3/4" | Forged | Steel | 1,830 | ASME B30.26 | ——— | 0 | 1757N17 | 000000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/8" | 8 17/32" | 1 1/4" | 27/32" | Forged | Steel | 2,620 | ASME B30.26 | 1757N14 | 000000 | 1757N18 | 000000 | |