View a wire gauge conversion chart.

Low-Carbon Steel Wire

- Heat Treatment: Annealed (Softened)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Not Rated

- Tensile Strength: 70,000 psi

- Fabrication: Cold Drawn

- Specifications Met: ASTM A853

Also known as black-annealed wire, this low-carbon steel wire will stay in place when bent. It's commonly used for bundling and as tag wire. Wire adheres to strict ASTM A853 standards for manufacturing and performance.

Container | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Lg., ft. | Color | Max. Temperature, °F | Net Weight, lbs. | Type | Each | |

Matte | ||||||||

| 0.048" | -0.003" to 0.003" | 41 | Dark Gray | 300° | 1/4 | Spool | 0000000 | 00000 |

| 0.048" | -0.003" to 0.003" | 165 | Dark Gray | 300° | 1 | Spool | 0000000 | 0000 |

| 0.048" | -0.003" to 0.003" | 830 | Dark Gray | 300° | 5 | Spool | 0000000 | 00000 |

| 0.048" | -0.003" to 0.003" | 1,660 | Dark Gray | 300° | 10 | Coil | 0000000 | 00000 |

| 0.048" | -0.003" to 0.003" | 16,600 | Dark Gray | 300° | 100 | Coil | 00000000 | 000000 |

Zinc-Galvanized Steel Wire

Spool |  Coil |

1-ft. Length |

- Heat Treatment: Annealed (Softened)

- Heat Treatable: No

- Tensile Strength: 70,000 psi

- Fabrication: Cold Drawn

- Specifications Met: ASTM A641

This wire is zinc galvanized for good corrosion resistance. It will stay in place when bent, so it’s commonly used for bundling and as tag wire. All meet ASTM A641 standards for performance and quality.

1 ft. Lg. | |||||

|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Max. Temperature, °F | Pkg. Qty. | Pkg. | |

| 0.048" | -0.003" to 0.003" | 300° | 50 | 0000000 | 000000 |

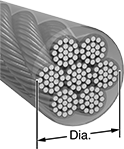

Extra-Flexible Low-Stretch Coated Wire Rope—Not for Lifting

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys. For use in precision mechanical applications, this rope is stretched during fabrication to minimize elongation under load. This wire rope is coated with nylon.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

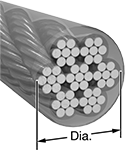

Low-Stretch Coated Wire Rope—Not for Lifting

For use in precision mechanical applications, this rope is stretched during fabrication to minimize elongation under load. This wire rope is coated with nylon. This stainless steel wire rope withstands outdoor and washdown applications. The construction of this wire rope provides a good balance of abrasion resistance and flexibility.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

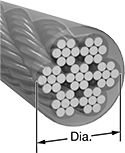

Coated Small-Diameter Braided Wire—Not for Lifting

The plastic coating protects this braided wire from abrasion. Made of 18-8 stainless steel, this wire rope has good corrosion resistance. This wire rope provides a good balance of abrasion resistance and flexibility.

Preformed wire rope maintains its shape when cut and resists unraveling.

Extra-lubricated wire rope has an additional coating of lubrication for added wear and corrosion resistance.

Strand core are more crush resistant than hollow core.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

| Dia. | Dia. with Coating | Capacity, lbs. | Recommended Pulley/Drum Dia. | Coating Material | Coating Color | Lubrication | Preformed | Temperature Range, °F | Specifications Met | Lengths, ft. | Per Ft. | |

18-8 Stainless Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

7 × 7—Strand Core | ||||||||||||

| 0.048" | 0.063" | 50 | 1 7/8" | Nylon Plastic | Clear | Extra Lubricated | Yes | -30 to 180° | MIL-DTL-83420 | 0000000 | 00000 | |