Filter by

Component

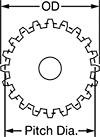

Gear Pitch Diameter

Thread Direction

Hub Diameter

Tooth Heat Treatment

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Metal Worms and Worm Gears

Worms

Keyway | Hub | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | Gear Pitch | Pressure Angle | Worm Lg. | Gear Pitch Dia. | OD | For Shaft Dia. | No. of Thread Starts | Wd. | Dp. | Dia., mm | Material | Thread Direction | Tooth Heat Treatment | Tooth Mechanical Finish | Set Screw Included | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Keyed Bore—1144 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 14 1/2° | 1 1/8" | 1" | 1.17" | 1/2" | 1 | 0.125" | 0.063" | — | — | Right Hand | Not Hardened | Unfinished | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 14 1/2° | 1 3/8" | 1 1/4" | 1.45" | 5/8" | 1 | 0.188" | 0.094" | — | — | Right Hand | Not Hardened | Unfinished | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 8 | 14 1/2° | 1 3/4" | 1 1/2" | 1.75" | 3/4" | 1 | 0.188" | 0.094" | — | — | Right Hand | Not Hardened | Unfinished | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 6 | 14 1/2° | 2 1/2" | 2" | 2.33" | 7/8" | 1 | 0.188" | 0.094" | — | — | Right Hand | Not Hardened | Unfinished | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Black-Oxide 1045 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 20° | 18 mm | 11 mm | 12 mm | 5 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 20° | 18 mm | 11 mm | 12 mm | 5 mm | 2 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 20° | 30 mm | 14 mm | 15.6 mm | 6 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 20° | 30 mm | 14 mm | 15.6 mm | 6 mm | 2 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 20° | 32 mm | 16 mm | 18 mm | 6 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 20° | 32 mm | 16 mm | 18 mm | 6 mm | 2 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 20° | 32 mm | 16 mm | 18 mm | 8 mm | 1 | — | — | — | — | Right Hand | Hardened | Ground | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.25 | — | 20° | 37 mm | 21 mm | 23.5 mm | 8 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 20° | 40 mm | 25 mm | 28 mm | 8 mm | 1 | — | — | 20 | 1045 Carbon Steel | Right Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 20° | 40 mm | 25 mm | 28 mm | 8 mm | 2 | — | — | 20 | 1045 Carbon Steel | Right Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 20° | 40 mm | 25 mm | 28 mm | 10 mm | 1 | — | — | 20 | 1045 Carbon Steel | Right Hand | Hardened | Ground | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | — | 14 1/2° | 46 mm | 31 mm | 35 mm | 12 mm | 1 | — | — | 25 | 1045 Carbon Steel | Left Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | — | 14 1/2° | 46 mm | 31 mm | 35 mm | 12 mm | 1 | — | — | 25 | 1045 Carbon Steel | Right Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | — | 14 1/2° | 46 mm | 31 mm | 35 mm | 12 mm | 2 | — | — | 25 | 1045 Carbon Steel | Right Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | — | 20° | 63 mm | 37 mm | 42 mm | 15 mm | 2 | — | — | 30 | 1045 Carbon Steel | Right Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 20° | 18 mm | 11 mm | 12 mm | 5 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 20° | 18 mm | 11 mm | 12 mm | 5 mm | 2 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 20° | 30 mm | 14 mm | 15.6 mm | 6 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 20° | 32 mm | 16 mm | 18 mm | 6 mm | 1 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 20° | 32 mm | 16 mm | 18 mm | 6 mm | 2 | — | — | — | — | Right Hand | Not Hardened | Unfinished | Yes | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 20° | 40 mm | 25 mm | 28 mm | 8 mm | 2 | — | — | 20 | 303 Stainless Steel | Right Hand | Not Hardened | Unfinished | No | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shaft-Mounted Worms

Shaft, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | Pressure Angle | Worm Lg., mm | Gear Pitch Dia., mm | OD, mm | Dia. | Lg. | No. of Thread Starts | Thread Direction | Tooth Heat Treatment | Tooth Mechanical Finish | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

4140 Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 20° | 12 | 9 | 10 | 6 | 65 | 1 | Right Hand | Hardened | Ground | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 20° | 12 | 9 | 10 | 6 | 65 | 2 | Right Hand | Hardened | Ground | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | 20° | 20 | 12 | 14 | 8 | 85 | 1 | Right Hand | Hardened | Ground | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | 20° | 20 | 12 | 14 | 8 | 85 | 2 | Right Hand | Hardened | Ground | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 20° | 30 | 16 | 18 | 18 | 140 | 1 | Right Hand | Hardened | Ground | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 20° | 40 | 25 | 28 | 26 | 190 | 1 | Right Hand | Hardened | Ground | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gears

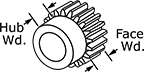

Hub | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | Gear Pitch | Speed Ratio | No. of Teeth | Pressure Angle | Gear Pitch Dia. | For No. of Thread Starts | OD | Face Wd. | Overall Wd. | For Shaft Dia. | Dia. | Wd. | Material | For Thread Direction | Tooth Heat Treatment | Tooth Mechanical Finish | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Cast Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 18:1 | 18 | 14 1/2° | 1 1/2" | 1 | 1.69" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 20:1 | 20 | 14 1/2° | 1.67" | 1 | 1.85" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 30:1 | 30 | 14 1/2° | 2 1/2" | 1 | 2.69" | 1/2" | 1.125" | 1/2" | 1.25" | 0.625" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 40:1 | 40 | 14 1/2° | 3.33" | 1 | 3.52" | 1/2" | 1.25" | 5/8" | 1.5" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 60:1 | 60 | 14 1/2° | 5" | 1 | 5.19" | 1/2" | 1.25" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 20:1 | 20 | 14 1/2° | 2" | 1 | 2.22" | 5/8" | 1.375" | 1/2" | 1.25" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 30:1 | 30 | 14 1/2° | 3" | 1 | 3.22" | 5/8" | 1.375" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 40:1 | 40 | 14 1/2° | 4" | 1 | 4.22" | 5/8" | 1.375" | 5/8" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.22" | 5/8" | 1.375" | 3/4" | 2" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 100:1 | 100 | 14 1/2° | 10" | 1 | 10.22" | 5/8" | 1.375" | 3/4" | 2.5" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 8 | 20:1 | 20 | 14 1/2° | 2 1/2" | 1 | 2.78" | 3/4" | 1.5" | 3/4" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 8 | 30:1 | 30 | 14 1/2° | 3 3/4" | 1 | 4.03" | 3/4" | 1.5" | 3/4" | 1.75" | 0.75" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 8 | 40:1 | 40 | 14 1/2° | 5" | 1 | 5.28" | 3/4" | 1.625" | 1" | 2.375" | 0.875" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 6 | 20:1 | 20 | 14 1/2° | 3.33" | 1 | 3.71" | 1" | 1.875" | 3/4" | 1.875" | 0.875" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 6 | 24:1 | 24 | 14 1/2° | 4" | 1 | 4.37" | 1" | 1.875" | 3/4" | 1.875" | 0.875" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 6 | 30:1 | 30 | 14 1/2° | 5" | 1 | 5.37" | 1" | 1.875" | 7/8" | 2.25" | 0.875" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 6 | 40:1 | 40 | 14 1/2° | 6.67" | 1 | 7.04" | 1" | 1.875" | 1" | 2.5" | 0.875" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 6 | 72:1 | 72 | 14 1/2° | 12" | 1 | 12.37" | 1" | 2.25" | 1 1/4" | 3" | 1.25" | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 60:1 | 60 | 20° | 60 mm | 1 | 63 mm | 10 mm | 20 mm | 10 mm | 30 mm | 10 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 80:1 | 80 | 20° | 80 mm | 1 | 83 mm | 10 mm | 20 mm | 10 mm | 35 mm | 10 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 100:1 | 100 | 20° | 100 mm | 1 | 103 mm | 10 mm | 20 mm | 10 mm | 40 mm | 10 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 120:1 | 120 | 20° | 120 mm | 1 | 123 mm | 10 mm | 20 mm | 10 mm | 40 mm | 10 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 30:1 | 30 | 20° | 45 mm | 1 | 49.5 mm | 12 mm | 22 mm | 10 mm | 30 mm | 10 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 40:1 | 40 | 20° | 60 mm | 1 | 64.5 mm | 12 mm | 22 mm | 12 mm | 30 mm | 10 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | — | 10:1 | 20 | 14 1/2° | 40 mm | 2 | 46 mm | 22 mm | 35 mm | 12 mm | 33 mm | 13 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | — | 20:1 | 20 | 14 1/2° | 40 mm | 1 | 46 mm | 22 mm | 35 mm | 12 mm | 33 mm | 13 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | — | 10:1 | 20 | 20° | 50 mm | 2 | 57.5 mm | 22 mm | 36 mm | 12 mm | 35 mm | 14 mm | Cast Iron | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 20:1 | 20 | 14 1/2° | 1.67" | 1 | 1.87" | 1/2" | 1" | 1/2" | 1.25" | 0.5" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 30:1 | 30 | 14 1/2° | 2 1/2" | 1 | 2.7" | 1/2" | 1.12" | 1/2" | 1.19" | 0.62" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 12 | 40:1 | 40 | 14 1/2° | 3.33" | 1 | 3.54" | 1/2" | 1.12" | 5/8" | 1.44" | 0.62" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 20:1 | 20 | 14 1/2° | 2" | 1 | 2.24" | 5/8" | 1.245" | 1/2" | 1.25" | 0.62" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 30:1 | 30 | 14 1/2° | 3" | 1 | 3.24" | 5/8" | 1.245" | 5/8" | 1.69" | 0.62" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 40:1 | 40 | 14 1/2° | 4" | 1 | 4.24" | 5/8" | 1.245" | 5/8" | 1.69" | 0.62" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | 10 | 50:1 | 50 | 14 1/2° | 5" | 1 | 5.24" | 5/8" | 1.375" | 3/4" | 1.94" | 0.75" | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 10:1 | 20 | 20° | 10 mm | 2 | 11 mm | 5 mm | 12 mm | 4 mm | 9 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 15:1 | 30 | 20° | 15 mm | 2 | 16 mm | 5 mm | 12 mm | 4 mm | 12 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 20:1 | 20 | 20° | 10 mm | 1 | 11 mm | 5 mm | 12 mm | 4 mm | 9 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 30:1 | 30 | 20° | 15 mm | 1 | 16 mm | 5 mm | 12 mm | 4 mm | 12 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 40:1 | 40 | 20° | 20 mm | 1 | 21 mm | 5 mm | 12 mm | 5 mm | 15 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 50:1 | 50 | 20° | 25 mm | 1 | 26 mm | 5 mm | 12 mm | 5 mm | 20 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | — | 60:1 | 60 | 20° | 30 mm | 1 | 31 mm | 5 mm | 12 mm | 5 mm | 25 mm | 7 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 10:1 | 20 | 20° | 16 mm | 2 | 17.6 mm | 9 mm | 18 mm | 5 mm | 12 mm | 9 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 20:1 | 20 | 20° | 16 mm | 1 | 17.6 mm | 9 mm | 18 mm | 5 mm | 12 mm | 9 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 30:1 | 30 | 20° | 24 mm | 1 | 25.6 mm | 9 mm | 18 mm | 5 mm | 18 mm | 9 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | — | 40:1 | 40 | 20° | 32 mm | 1 | 33.6 mm | 9 mm | 18 mm | 6 mm | 20 mm | 9 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 10:1 | 20 | 20° | 20 mm | 2 | 23 mm | 10 mm | 20 mm | 6 mm | 16 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | — | 30:1 | 30 | 20° | 30 mm | 1 | 33 mm | 10 mm | 20 mm | 6 mm | 20 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.25 | — | 20:1 | 20 | 20° | 25 mm | 1 | 28.75 mm | 10 mm | 20 mm | 6 mm | 20 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 10:1 | 20 | 20° | 30 mm | 2 | 34.5 mm | 12 mm | 22 mm | 8 mm | 22 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 15:1 | 30 | 20° | 45 mm | 2 | 49.5 mm | 12 mm | 22 mm | 10 mm | 30 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 20:1 | 20 | 20° | 30 mm | 1 | 34.5 mm | 12 mm | 22 mm | 8 mm | 22 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | — | 30:1 | 30 | 20° | 45 mm | 1 | 49.5 mm | 12 mm | 22 mm | 10 mm | 30 mm | 10 mm | Bronze | Right Hand | Not Hardened | Unfinished | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Worm Gears

Gears

Hub, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Gear Module | Speed Ratio | No. of Teeth | Pressure Angle | Gear Pitch Dia., mm | For No. of Thread Starts | OD, mm | Face Wd., mm | Overall Wd., mm | For Shaft Dia., mm | Fabrication | Color | Dia. | Wd. | For Thread Direction | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 10:1 | 20 | 20° | 10 | 2 | 11 | 5 | 12 | 4 | Molded | White | 9 | 7 | Right Hand | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 20:1 | 20 | 20° | 10 | 1 | 11 | 5 | 12 | 4 | Molded | White | 9 | 7 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 30:1 | 30 | 20° | 15 | 1 | 16 | 5 | 12 | 4 | Molded | White | 12 | 7 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 40:1 | 40 | 20° | 20 | 1 | 21 | 5 | 12 | 5 | Molded | White | 15 | 7 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 50:1 | 50 | 20° | 25 | 1 | 26 | 5 | 12 | 5 | Molded | White | 20 | 7 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5 | 60:1 | 60 | 20° | 30 | 1 | 31 | 5 | 12 | 5 | Molded | White | 25 | 7 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | 10:1 | 20 | 20° | 16 | 2 | 17.6 | 9 | 18 | 5 | Molded | White | 12 | 9 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | 50:1 | 50 | 20° | 40 | 1 | 41.6 | 9 | 18 | 8 | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 | 60:1 | 60 | 20° | 48 | 1 | 49.6 | 9 | 18 | 8 | Molded | White | 25 | 9 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Bore—Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 10:1 | 20 | 20° | 20 | 2 | 23 | 10 | 20 | 6 | Molded | Blue | 16 | 10 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 30:1 | 30 | 20° | 30 | 1 | 33 | 10 | 20 | 6 | Molded | Blue | 20 | 10 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 50:1 | 50 | 20° | 50 | 1 | 53 | 10 | 20 | 8 | Molded | Blue | 30 | 10 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | 10:1 | 20 | 20° | 30 | 2 | 34.5 | 12 | 22 | 8 | Molded | Blue | 22 | 10 | Right Hand | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||