How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Backflow-Prevention Valves

More

About On/Off Valves

More

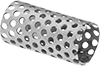

About Strainers and Selecting Screen Size

More

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line. 304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Fabrication: Heat Treated

- Specifications Met: ASTM A351

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Connectors with NPT threads are threaded on both ends.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASME B16.3, UL Listed, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1 1/4 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | 000000000 | 000000 |

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

The galvanized finish on these fittings provides fair corrosion resistance. Fittings are for use in low-pressure applications.

- Pressure Class: 150

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A197, UL Listed, ASME B16.3, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1 1/4 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

High-Pressure Iron and Steel Threaded Pipe Fittings

These fittings can stand up to high-pressure applications. Use them in noncorrosive environments.

Note: The maximum pressure listed for Class 3000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASTM A105, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | ||||||

|---|---|---|---|---|---|---|

| 1 1/4 | 20 | 3,000 psi @ 72° F | 300 psi @ 360° F | Steel | 0000000 | 0000000 |

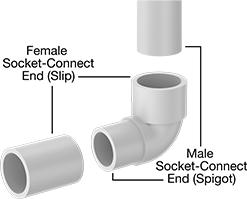

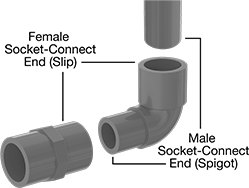

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

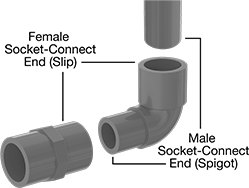

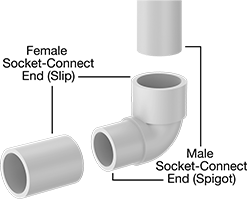

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 1 1/4 | 1 1/4" | PVC Plastic | White | 00000000 | 00000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

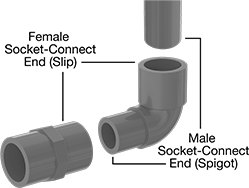

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 1 1/4 | 1 1/4" | PVC Plastic | Dark Gray | 00000000 | 000000 |

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

| Pipe Size | Socket Depth | Material | Schedule | Color | Max. Pressure | Each | |

| 1 1/4 | 1 1/4" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

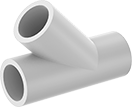

Aboveground Standard-Wall PVC Pipe Fittings for Drain, Waste, and Vent

- For Use With: Water

- Max. Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2665

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

These Schedule 40 fittings are the industry standard for gravity-flow drain, waste, and vent (DWV) applications. Fittings are PVC, which has good corrosion resistance. They meet ASTM D1784 and ASTM D2665 specifications and testing requirements for material quality.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Drain, Waste, and Vent ABS Pipe Fittings for Chemicals

These Schedule 40 fittings are an economical option for gravity-flow chemical waste systems. They are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Fittings meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

- For Use With: Sodium Hydroxide

- Maximum Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe Nipples and Pipe: Use Schedule 40 ABS Plastic

- Flanges: Use Schedule 40 ABS Plastic

PVC Y-Strainers

- For Use With:

Dark Gray: Water and Diesel Fuel

Clear: Water - Max. Pressure: 150 psi @ 70° F

- Temp. Range:

Dark Gray: 40° to 140° F

Clear: 40° to 120° F

PVC construction is lightweight and provides excellent corrosion resistance. Install them prior to valves, pumps, and nozzles to catch debris in your pipeline and protect sensitive equipment. Strainers have a threaded drain with a hex cap or plug that provides access to the screen without disconnecting your line.

Strainers with socket-connect pipe connections attach to unthreaded pipe with cement for a permanent, leak-tight connection.

Strainers | Replacement Screens | Replacement Caps | Replacement Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | For Fitting Schedule | For Pipe Schedule | Features | Choose a Screen Opening Size | Each | Each | Each | Each | ||||

Dark Gray Strainer with PVC Plastic Screen | |||||||||||||||

| 1 1/4 | NPT | 6 5/8" | 5 15/16" | 80 | 80 | Threaded Drain with Hex Cap | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

Strainers | Replacement Screens | Replacement Caps | Replacement Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Connect Type | Lg. | Ht. | For Fitting Schedule | For Pipe Schedule | Features | Choose a Screen Opening Size | Each | Each | Each | Each | ||||

Dark Gray Strainer with PVC Plastic Screen | |||||||||||||||

| 1 1/4 | Cement | 6 5/8" | 5 15/16" | 80 | 80 | Threaded Drain with Hex Cap | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

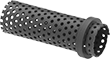

Screens for PVC Y-Strainers

Mesh screens typically filter smaller particles than perforated screens. To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

Polypropylene Y-Strainers

- Max. Pressure for Water: See Table

- Temp. Range: -20° to 150° F

These irrigation polypropylene strainers have excellent corrosion resistance and are lightweight. Install them in your pipeline to trap debris and prevent damage to valves, pumps, nozzles, and other sensitive equipment. They have a threaded drain with a plug that provides access to the screen without disconnecting your line.

Screens for Polypropylene Y-Strainers

To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

For technical drawings and 3-D models, click on a part number.

Low-Pressure Iron Y-Strainers

A rugged iron body provides excellent strength and durability. Strainers prevent damage to valves, pumps, nozzles, and other sensitive equipment by catching debris in your pipeline. They are designed for low-pressure applications. Strainers are for use in noncorrosive environments. They have a threaded drain with a plug that provides access to the screen without disconnecting your line.

Strainers | Replacement Screens | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Lg. | Ht. | Plug Pipe Size | Screen Material | Choose a Screen Mesh Size | Choose a Screen Opening Size | Each | Each | ||

With Mesh Screen | ||||||||||

| 1 1/4 | 5 1/8" | 5 15/16" | 3/4 | 304 Stainless Steel | 20 | __ | 0000000 | 000000 | 0000000 | 000000 |

With Mesh and Perforated Screen | ||||||||||

| 1 1/4 | 5 1/8" | 5 15/16" | 3/4 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

With Perforated Screen | ||||||||||

| 1 1/4 | 5 1/8" | 5 15/16" | 3/4 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

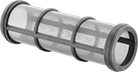

Screens for Low-Pressure Iron Y-Strainers

Mesh screens typically filter smaller particles than perforated screens. To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

| For Pipe Size | Screen OD | Screen Length | Screen Material | Screen Mesh Size | Screen Opening Size | Each | ||

Mesh | ||||||||

|---|---|---|---|---|---|---|---|---|

| A | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 20 | __ | 0000000 | 000000 |

Mesh and Perforated | ||||||||

| B | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 40 | __ | 00000000 | 00000 |

| B | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 60 | __ | 00000000 | 00000 |

| B | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 80 | __ | 00000000 | 00000 |

| B | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 100 | __ | 00000000 | 00000 |

| B | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 150 | __ | 00000000 | 00000 |

| B | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | 200 | __ | 00000000 | 00000 |

Perforated | ||||||||

| C | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | __ | 1/32" | 00000000 | 00000 |

| C | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | __ | 1/16" | 00000000 | 00000 |

| C | 1 1/4 | 1 13/32" | 4 1/4" | 304 Stainless Steel | __ | 1/8" | 00000000 | 00000 |

Medium-Pressure Iron and Steel Y-Strainers

- Max. Pressure for Water, Oil, and Inert Gas:

Iron: 600 psi @ 100° F

Steel: 700 psi @ 100° F

Max. Pressure for Steam:

Iron: 450 psi @ 650° F

Steel: 300 psi @ 400° F - Temp. Range:

Iron: -20° to 650° F

Steel: -20° to 400° F

Made of rugged iron or steel, these strainers provide excellent strength and durability. Install them prior to valves, pumps, and nozzles to protect sensitive equipment from damage caused by debris. They are designed for medium-pressure applications. Strainers are for use in noncorrosive environments. They have a threaded drain with a plug that provides access to the screen without disconnecting your line.

Screens for Medium-Pressure Iron and Steel Y-Strainers

Low-Pressure Bronze Y-Strainers

- Max. Pressure for Water, Oil, Inert Gas, and Diesel Fuel: 200 psi @ 70° F

Max. Pressure for Steam: 125 psi @ 400° F - Temp. Range: -20° to 400° F

Install these strainers prior to valves, pumps, and nozzles to catch debris in your pipeline and protect sensitive equipment. They are designed for low-pressure applications. Strainers have a threaded drain with a plug that provides access to the screen without disconnecting your line. They are bronze for good corrosion resistance.

Strainers | Replacement Screens | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Plug Pipe Size | Screen Material | Screen OD | Screen Lg. | Choose a Screen Mesh Size | Choose a Screen Opening Size | Each | Each | ||

With Mesh Screen | |||||||||||||

| 1 1/4 | NPT | 5 5/16" | 4 3/4" | 1/2 | 304 Stainless Steel | 1 27/64" | 3 11/64" | 20 | __ | 00000000 | 000000 | 000000000 | 000000 |

| 1 1/4 | NPT | 5 5/16" | 4 3/4" | 1/2 | 304 Stainless Steel | 1 27/64" | 3 11/64" | __ | 00000000 | 000000 | 00000000 | 00000 | |

With Perforated Screen | |||||||||||||

| 1 1/4 | NPT | 5 5/16" | 4 3/4" | 1/2 | 304 Stainless Steel | 1 7/16" | 3 3/16" | __ | 000000000 | 000000 | 000000000 | 00000 | |

Screens for Low-Pressure Bronze Y-Strainers

Mesh screens typically filter smaller particles than perforated screens. To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

Medium-Pressure Bronze and Brass Y-Strainers

- Max. Pressure: See Table

- Max. Steam Pressure:

Brass: Not Rated

Bronze: 235 psi @ 400° F - Temp. Range:

Brass: 35° to 350° F

Bronze: -20° to 400° F

Strainers catch debris in your pipeline, preventing damage to valves, pumps, nozzles, and other sensitive equipment. They are designed for medium-pressure applications. Strainers have a threaded drain with a plug that provides access to the screen without disconnecting your line. They have good corrosion resistance.

Screens for Medium-Pressure Bronze and Brass Y-Strainers

Mesh screens typically filter smaller particles than perforated screens. To replace your screen, measure the OD and length and find the corresponding screen listed in the table.

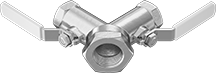

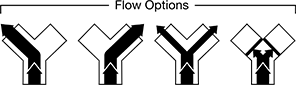

Dual Shut-Off Threaded Diverting Valves

- Valve Type: Ball

- For Use With:

NPT Female × NPT Female × NPT Female: Air, Water

NPT Female × NPT Male × NPT Male: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon - Seal Material: PTFE Plastic

Control flow in two directions from a single source—these valves have two handles for independent operation of each outlet. They can direct flow from the center-port inlet to one side-port outlet at full capacity, direct flow to both side-port outlets simultaneously at reduced capacity, or shut off flow to both outlet ports completely. Valves are standard port, so they slightly restrict flow.

| Inlet Pipe Size | Outlet Pipe Sizes | Flow Pattern | Max. Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Bronze Body | ||||||||

|---|---|---|---|---|---|---|---|---|

NPT Female × NPT Female × NPT Female | ||||||||

| 1 1/4 | 3/4 × 3/4 | Y-Pattern | 550 psi @ 150° F | Not Rated | 29 | 3 7/16" | 0000000 | 0000000 |

High-Flow Threaded Check Valves

To achieve the maximum possible flow, internal components are designed to reduce flow resistance. These valves open to allow flow in one direction and close when flow stops or reverses. A removable cap provides easy access to internal components for maintenance.

Repair kits include everything you need to rebuild the valve.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Air, Argon, Helium, Krypton, Neon, Steam, Water, Xenon

- Disc Material: See table

- Seal Material: See table

Valves | Repair Kits | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Disc Material | Seal Material | End-to-End Lg. | Features | Each | Each | ||

NPT Female × NPT Female—Pressure Class 150 | |||||||||||||

| 1 1/4 | 39 | 300 psi @ 150° F | 150 psi @ 366° F | 0.5 | -20° to 405° | Brass | Brass | 4 3/8" | Removable Cap | 0000000 | 0000000 | 000000 | 00 |

NPT Female × NPT Female—Pressure Class 200 | |||||||||||||

| 1 1/4 | 39 | 400 psi @ 150° F | 200 psi @ 388° F | 0.5 | -20° to 550° | Bronze | Bronze | 4 3/8" | Removable Cap | 0000000 | 000000 | 00000000 | 0000000 |

NPT Female × NPT Female—Pressure Class 300 | |||||||||||||

| 1 1/4 | 39 | 600 psi @ 150° F | 300 psi @ 422° F | 0.5 | -20° to 550° | Bronze | Bronze | 4 3/8" | Removable Cap | 0000000 | 000000 | 00000000 | 000000 |

Socket-Connect Check Valves for Harsh Chemicals

Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. These valves have a plastic body and a fluoroelastomer seal for excellent chemical resistance. They open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Citric Acid, Deionized Water, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Mineral Spirits, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Sodium Hypochlorite, Water

- Piston Material: PVC Plastic

- Spring Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

Socket Connect × Socket Connect | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 1/4 | 40, 80 | 26 | 150 psi @ 70° F | 2 | 40° to 140° | Dark Gray | 6 5/8" | 000000 | 0000000 |

Aluminum Slip-On Framing and Fittings

Half the weight of steel, this aluminum framing resists corrosion in wet environments. Slip the fittings over rails to construct custom railings, guard rails, storage racks, and shelving. Tighten the included set screws for a secure hold.

Anodized aluminum resists corrosion and wear better than uncoated aluminum and has a finished appearance.

Black powder-coated aluminum blends in with backgrounds and hides dirt and grime.

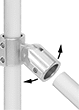

Adjustable-angle fittings can be positioned at any angle. Tighten the set screw to secure.

Fittings that meet UL 2703 are approved for use in solar rack mounting systems.

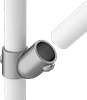

Through-hole fittings allow rails to run all the way through.

Anodized aluminum resists corrosion and wear better than uncoated aluminum and has a finished appearance.

Black powder-coated aluminum blends in with backgrounds and hides dirt and grime.

Adjustable-angle fittings can be positioned at any angle. Tighten the set screw to secure.

Fittings that meet UL 2703 are approved for use in solar rack mounting systems.

| For Rail OD | For Pipe Size | No. of Through Holes | Includes | Specifications Met | Each | |

45° Wye | ||||||

|---|---|---|---|---|---|---|

Aluminum | ||||||

| 1 5/8" | 1 1/4 | 1 | Set Screws | __ | 00000000 | 000000 |

Adjustable-Angle Wye | ||||||

Aluminum | ||||||

| 1 5/8" | 1 1/4 | 1 | Set Screws | UL 2703 | 0000000 | 00000 |

Anodized Aluminum | ||||||

| 1 5/8" | 1 1/4 | 1 | Set Screws | UL 2703 | 00000000 | 00000 |

Black Powder-Coated Aluminum | ||||||

| 1 5/8" | 1 1/4 | 1 | Set Screws | UL 2703 | 00000000 | 00000 |

Galvanized Iron and Steel Slip-On Framing and Fittings

To provide corrosion resistance in wet environments, this framing is galvanized. Slip the fittings over rails to construct custom railings, guard rails, storage racks, and shelving. Tighten the included set screws for a secure hold.

Galvanized iron fittings are malleable iron.

Through-hole fittings allow rails to run all the way through.

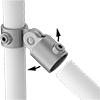

Adjustable-angle fittings can be positioned at any angle. Tighten the set screw to secure.