How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

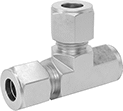

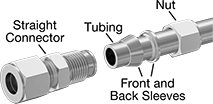

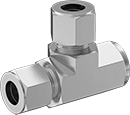

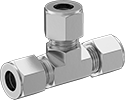

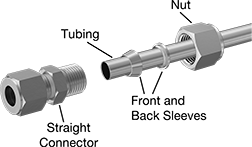

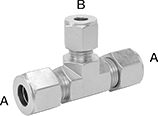

Yor-Lok Fittings for Stainless Steel Tubing

(SAE Straight) Male

Threads with Gasket

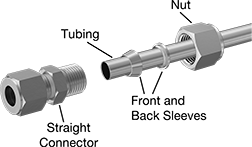

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

BSPP and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

(SAE Straight) Male

Threads with Gasket

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Right-angle tees are also known as run tees.

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Thread Size | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

BSPP Threads | |||||||||

| 1/4" | 0.035" | 1/4 | __ | 316 Stainless Steel | Buna-N Rubber | 4,000 psi @ 72° F | -30° to 250° | 00000000 | 000000 |

| 1/2" | 0.035" | 1/2 | __ | 316 Stainless Steel | Buna-N Rubber | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

NPT Threads | |||||||||

| 1/8" | 0.035" | 1/8 | __ | 316 Stainless Steel | __ | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/8" | 0.035" | 1/4 | __ | 316 Stainless Steel | __ | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/16" | 0.035" | 1/8 | __ | 316 Stainless Steel | __ | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8 | __ | 316 Stainless Steel | __ | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/4 | __ | 316 Stainless Steel | __ | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 3/8 | __ | 316 Stainless Steel | __ | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/2 | __ | 316 Stainless Steel | __ | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/16" | 0.035" | 1/8 | __ | 316 Stainless Steel | __ | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | __ | 316 Stainless Steel | __ | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 3/8 | __ | 316 Stainless Steel | __ | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4 | __ | 316 Stainless Steel | __ | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 3/8 | __ | 316 Stainless Steel | __ | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/2 | __ | 316 Stainless Steel | __ | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 1/2 | __ | 316 Stainless Steel | __ | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/4" | 0.049" | 3/4 | __ | 316 Stainless Steel | __ | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

UN/UNF (SAE Straight) Threads | |||||||||

| 1/4" | 0.035" | __ | 7/16"-20 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | __ | 9/16"-18 | 316 Stainless Steel | Fluoroelastomer Rubber | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | __ | 3/4"-16 | 316 Stainless Steel | Fluoroelastomer Rubber | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Right-angle tees are also known as run tees.

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 1/8" | 0.035" | 1/8 | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/4" | 0.035" | 1/8 | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/4" | 0.035" | 1/4 | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/2" | 0.035" | 3/8 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1/2" | 0.035" | 1/2 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 3/4" | 0.049" | 3/4 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

| 1" | 0.065" | 1 | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1 1/4" | 0.083" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

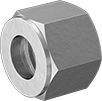

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | 0.035" | 316 Stainless Steel | 6,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/16" | 0.035" | 316 Stainless Steel | 5,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 4,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 2,500 psi @ 72° F | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 0.049" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1" | 0.065" | 316 Stainless Steel | 1,500 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

| 1 1/4" | 0.083" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 00000 |

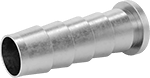

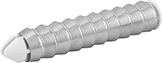

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 1/8" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 6,000 psi @ 72° F | 00000000 | 00000 |

| 3/16" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 5,500 psi @ 72° F | 00000000 | 0000 |

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 4,000 psi @ 72° F | 00000000 | 0000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 3,000 psi @ 72° F | 00000000 | 0000 |

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 1 | 3/32" | 1 | 2,500 psi @ 72° F | 00000000 | 0000 |

| 1/2" | 0.035" | 316 Stainless Steel | 19/64" | 1 | 5/32" | 1 | 2,000 psi @ 72° F | 00000000 | 0000 |

| 5/8" | 0.049" | 316 Stainless Steel | 19/64" | 1 | 5/32" | 1 | 2,000 psi @ 72° F | 00000000 | 0000 |

| 3/4" | 0.049" | 316 Stainless Steel | 19/64" | 1 | 5/32" | 1 | 2,000 psi @ 72° F | 00000000 | 0000 |

| 1" | 0.065" | 316 Stainless Steel | 3/8" | 1 | 13/64" | 1 | 1,500 psi @ 72° F | 00000000 | 00000 |

| 1 1/4" | 0.083" | 316 Stainless Steel | 35/64" | 1 | 13/64" | 1 | 2,000 psi @ 72° F | 00000000 | 00000 |

Sleeves with Dispenser | |||||||||

| 1/8" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 3/32" | 10 | 6,000 psi @ 72° F | 00000000 | 00000 |

| 3/16" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 3/32" | 10 | 5,500 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 7/64" | 10 | 4,000 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 7/64" | 10 | 3,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 10 | 7/64" | 10 | 2,500 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 10 | 5/32" | 10 | 2,000 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 9/32" | 10 | 5/32" | 10 | 2,000 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.049" | 316 Stainless Steel | 9/32" | 10 | 5/32" | 10 | 1,900 psi @ 72° F | 00000000 | 00000 |

| 1" | 0.065" | 316 Stainless Steel | 3/8" | 10 | 13/64" | 10 | 1,500 psi @ 72° F | 00000000 | 000000 |

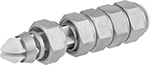

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each front sleeve, back sleeve, and nut is made of 316 stainless steel for excellent corrosion resistance. Five sets of sleeves and nuts come on each dispenser. Sleeves are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sets with Dispenser | |||||||||||

| 1/8" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 3/32" | 5 | 15/32" | 5 | 6,000 psi @ 72° F | 0000000 | 000000 |

| 3/16" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 3/32" | 5 | 15/32" | 5 | 5,500 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 1/2" | 5 | 4,000 psi @ 72° F | 0000000 | 00000 |

| 5/16" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 17/32" | 5 | 3,000 psi @ 72° F | 0000000 | 00000 |

| 3/8" | 0.035" | 316 Stainless Steel | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 2,500 psi @ 72° F | 0000000 | 00000 |

| 1/2" | 0.035" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 2,000 psi @ 72° F | 0000000 | 00000 |

| 5/8" | 0.049" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 2,000 psi @ 72° F | 0000000 | 000000 |

| 3/4" | 0.049" | 316 Stainless Steel | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,900 psi @ 72° F | 0000000 | 000000 |

| 1" | 0.065" | 316 Stainless Steel | 3/8" | 5 | 13/64" | 5 | 13/16" | 5 | 1,500 psi @ 72° F | 0000000 | 000000 |

PTFE sleeves are plastic instead of stainless steel, so they won’t damage tubing.

| For Tube OD | Sleeve Material | Max. Pressure | Temp. Range, °F | Each | |

| 1/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 3/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 5/16" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 3/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 1/2" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 0000 |

| 5/8" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 3/4" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

| 1" | PTFE Plastic | Not Rated | -65° to 350° | 00000000 | 00000 |

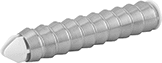

Tube supports are recommended for soft plastic tubing to prevent the tube from collapsing.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | ID | Tube Support Material | Tube Support Style | Temp. Range, °F | Each | |

| 3/16" | 1/8" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 000000 |

| 1/4" | 1/8" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.17" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 1/4" | 0.188" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 1/8" | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 3/16" | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 0000 |

| 5/16" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 3/8" | 0.188" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 3/8" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 1/2" | 1/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 1/2" | 3/8" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 0000 |

| 5/8" | 3/8" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 1/2" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

| 3/4" | 5/8" | 316 Stainless Steel | Barbed | -420° to 1200° | 00000000 | 00000 |

| 1" | 3/4" | 316 Stainless Steel | Smooth | -420° to 1200° | 00000000 | 00000 |

Yor-Lok Fittings for Copper Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ASME B31.3

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are brass for good corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

Right-angle tees are also known as run tees.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | ||||||

| 1/8" | 0.035" | 1/8 | Brass | 2,900 psi @ 72° F | 00000000 | 000000 |

| 1/8" | 0.035" | 1/4 | Brass | 2,900 psi @ 72° F | 00000000 | 00000 |

| 3/16" | 0.035" | 1/8 | Brass | 2,300 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/8 | Brass | 1,600 psi @ 72° F | 00000000 | 00000 |

| 1/4" | 0.035" | 1/4 | Brass | 1,600 psi @ 72° F | 00000000 | 00000 |

| 5/16" | 0.035" | 1/8 | Brass | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/8 | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 3/8" | 0.035" | 1/2 | Brass | 1,000 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 1/4 | Brass | 800 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 3/8 | Brass | 800 psi @ 72° F | 00000000 | 00000 |

| 1/2" | 0.035" | 1/2 | Brass | 800 psi @ 72° F | 00000000 | 00000 |

| 5/8" | 0.049" | 1/2 | Brass | 900 psi @ 72° F | 00000000 | 00000 |

| 3/4" | 0.049" | 3/4 | Brass | 700 psi @ 72° F | 00000000 | 000000 |

Inline tees are also known as branch tees.

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1/8" | Brass | 2,900 psi @ 72° F | 00000000 | 00000 |

| 3/16" | Brass | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 800 psi @ 72° F | 00000000 | 0000 |

| 5/8" | Brass | 900 psi @ 72° F | 00000000 | 0000 |

| 3/4" | Brass | 700 psi @ 72° F | 00000000 | 0000 |

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/8" | Brass | 3/16" | 1 | 3/32" | 1 | 2,900 psi @ 72° F | 00000000 | 00000 |

| 3/16" | Brass | 3/16" | 1 | 3/32" | 1 | 2,300 psi @ 72° F | 00000000 | 0000 |

| 1/4" | Brass | 3/16" | 1 | 3/32" | 1 | 1,600 psi @ 72° F | 00000000 | 0000 |

| 5/16" | Brass | 3/16" | 1 | 3/32" | 1 | 1,300 psi @ 72° F | 00000000 | 0000 |

| 3/8" | Brass | 3/16" | 1 | 3/32" | 1 | 1,000 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Brass | 19/64" | 1 | 5/32" | 1 | 800 psi @ 72° F | 00000000 | 0000 |

| 5/8" | Brass | 19/64" | 1 | 5/32" | 1 | 900 psi @ 72° F | 00000000 | 00000 |

| 3/4" | Brass | 19/64" | 1 | 5/32" | 1 | 700 psi @ 72° F | 00000000 | 0000 |

Save time installing sleeves—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each set includes a front and back sleeve. The sleeves are also known as ferrules.

Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/8" | Brass | 3/16" | 10 | 7/64" | 10 | 2,800 psi @ 72° F | 00000000 | 000000 |

| 3/16" | Brass | 3/16" | 10 | 7/64" | 10 | 1,800 psi @ 72° F | 00000000 | 00000 |

| 1/4" | Brass | 3/16" | 10 | 7/64" | 10 | 1,300 psi @ 72° F | 00000000 | 00000 |

| 5/16" | Brass | 3/16" | 10 | 7/64" | 10 | 1,300 psi @ 72° F | 00000000 | 00000 |

| 3/8" | Brass | 3/16" | 10 | 7/64" | 10 | 1,100 psi @ 72° F | 00000000 | 00000 |

| 1/2" | Brass | 19/64" | 10 | 9/64" | 10 | 1,200 psi @ 72° F | 00000000 | 00000 |

| 5/8" | Brass | 3/16" | 10 | 7/64" | 10 | 1,250 psi @ 72° F | 00000000 | 00000 |

| 3/4" | Brass | 9/32" | 10 | 5/32" | 10 | 1,000 psi @ 72° F | 00000000 | 00000 |

Save time installing sleeves and nuts—these sets come oriented in the correct direction and order on a dispenser. To install them, slide off a set and place it on your tubing. Each set includes a front sleeve, a back sleeve, and a nut. The sleeves are also known as ferrules.

Front Sleeve | Back Sleeve | Nut | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Material | Lg. | No. Included | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

| 1/8" | Brass | 3/16" | 5 | 7/64" | 5 | 15/32" | 5 | 2,800 psi @ 72° F | 0000000 | 000000 |

| 3/16" | Brass | 3/16" | 5 | 7/64" | 5 | 15/32" | 5 | 1,800 psi @ 72° F | 0000000 | 00000 |

| 1/4" | Brass | 3/16" | 5 | 7/64" | 5 | 1/2" | 5 | 1,300 psi @ 72° F | 0000000 | 00000 |

| 5/16" | Brass | 3/16" | 5 | 7/64" | 5 | 17/32" | 5 | 1,300 psi @ 72° F | 0000000 | 00000 |

| 3/8" | Brass | 3/16" | 5 | 7/64" | 5 | 9/16" | 5 | 1,100 psi @ 72° F | 0000000 | 00000 |

| 1/2" | Brass | 3/16" | 5 | 7/64" | 5 | 11/16" | 5 | 1,200 psi @ 72° F | 0000000 | 00000 |

| 5/8" | Brass | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,250 psi @ 72° F | 0000000 | 00000 |

| 3/4" | Brass | 9/32" | 5 | 5/32" | 5 | 11/16" | 5 | 1,000 psi @ 72° F | 0000000 | 00000 |

For Tube | Tube Support | |||||

|---|---|---|---|---|---|---|

| OD | ID | Style | Material | Max. Pressure | Each | |

| 3/16" | 1/8" | Barbed | Brass | 1,800 psi @ 72° F | 0000000 | 00000 |

| 1/4" | 1/8" | Smooth | Brass | 1,300 psi @ 72° F | 0000000 | 0000 |

| 1/4" | 0.17" | Smooth | Brass | 1,300 psi @ 72° F | 0000000 | 0000 |

| 1/4" | 0.188" | Smooth | Brass | 1,300 psi @ 72° F | 0000000 | 0000 |

| 5/16" | 1/8" | Barbed | Brass | 1,300 psi @ 72° F | 0000000 | 0000 |

| 5/16" | 3/16" | Barbed | Brass | 1,300 psi @ 72° F | 0000000 | 0000 |

| 5/16" | 1/4" | Barbed | Brass | 1,300 psi @ 72° F | 0000000 | 0000 |

| 3/8" | 3/16" | Barbed | Brass | 1,100 psi @ 72° F | 0000000 | 0000 |

| 3/8" | 1/4" | Barbed | Brass | 1,100 psi @ 72° F | 0000000 | 0000 |

| 1/2" | 1/4" | Barbed | Brass | 1,200 psi @ 72° F | 0000000 | 0000 |

| 1/2" | 3/8" | Smooth | Brass | 800 psi @ 72° F | 0000000 | 0000 |

| 5/8" | 3/8" | Barbed | Brass | 1,250 psi @ 72° F | 0000000 | 0000 |

| 5/8" | 1/2" | Barbed | Brass | 1,250 psi @ 72° F | 0000000 | 0000 |

| 3/4" | 1/2" | Barbed | Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

| 3/4" | 5/8" | Barbed | Brass | 1,000 psi @ 72° F | 0000000 | 0000 |

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

Right-angle tees are also known as run tees.

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

NPT Threads | ||||||||

| 1/4" | 0.035" | 1/8 | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A179 | 00000000 | 000000 |

| 1/4" | 0.035" | 1/4 | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A179 | 00000000 | 00000 |

| 3/8" | 0.035" | 1/4 | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A179 | 00000000 | 00000 |

| 3/8" | 0.035" | 3/8 | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A179 | 00000000 | 000000 |

| 1/2" | 0.035" | 1/2 | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A179 | 00000000 | 00000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/4" | 0.035" | Zinc-Plated Steel | 4,900 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 00000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 3,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 2,300 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 0000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1/4" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 4,850 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |

| 3/8" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 3,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 0000 |

| 1/2" | 0.035" | Zinc-Plated Steel | 316 Stainless Steel | 2,300 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 00000 |