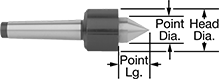

Live Centers for Intermittent Use

These light duty centers are for intermittent use on manual lathes. Use live centers in the tailstock to support the end of a workpiece. With bearings to support their free-turning point, they produce minimal friction between the center and workpiece. For increased tool life, the bearings are lubricated and sealed to protect against fluid and chips.

| Morse Taper Number | Max. Workpiece Capacity, lbs. | Point Dia. | Head Dia. | Point Lg. | Shank Lg. | Overall Lg. | Morse Taper Dia. | Max. Speed, rpm | Point Angle | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 1 | 220 | 0.59" | 1 1/2" | 45/64" | 2 3/32" | 4 1/16" | 0.475" | 5,000 | 60° | 0.0003" | Steel | 0000000 | 0000000 |

| 2 | 460 | 0.7" | 1 9/16" | 7/8" | 2 33/64" | 4 47/64" | 0.7" | 5,000 | 60° | 0.0003" | Steel | 0000000 | 000000 |

| 3 | 925 | 0.98" | 2 13/64" | 1 1/8" | 3 3/16" | 6 9/64" | 0.938" | 4,000 | 60° | 0.0003" | Steel | 0000000 | 000000 |

| 4 | 1,850 | 1.1" | 2 33/64" | 1 15/64" | 4 1/32" | 7 15/64" | 1.231" | 3,000 | 60° | 0.0003" | Steel | 0000000 | 000000 |

| 5 | 4,400 | 1.61" | 3 11/32" | 1 49/64" | 5 3/32" | 9 21/64" | 1.748" | 2,500 | 60° | 0.0003" | Steel | 0000000 | 000000 |

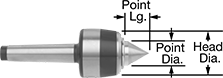

Live Centers for Continuous Use

A hardened body and point provide the extra strength and wear resistance necessary for continuous use on manual or CNC lathes. Use live centers in the tailstock to support the end of a workpiece. With bearings to support their free-turning point, they produce minimal friction between the center and workpiece. For increased tool life, the bearings are lubricated and sealed to protect against fluid and chips.

| Morse Taper Number | Max. Workpiece Capacity, lbs. | Point Dia. | Head Dia. | Point Lg. | Shank Lg. | Overall Lg. | Morse Taper Dia. | Max. Speed, rpm | Point Angle | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 2 | 725 | 7/8" | 1 3/4" | 1 1/64" | 2 13/16" | 5 19/64" | 0.7" | 6,000 | 60° | 0.00005" | Hardened Steel | 0000000 | 0000000 |

| 3 | 970 | 1" | 2 11/32" | 1 15/64" | 3 7/16" | 6 13/32" | 0.938" | 5,000 | 60° | 0.00005" | Hardened Steel | 0000000 | 000000 |

| 4 | 1,720 | 1 1/4" | 2 11/16" | 1 31/64" | 4 15/32" | 7 57/64" | 1.231" | 4,500 | 60° | 0.00005" | Hardened Steel | 0000000 | 00000000 |

| 5 | 3,260 | 1 1/2" | 3 29/64" | 1 27/32" | 5 35/64" | 10 13/64" | 1.748" | 3,500 | 60° | 0.00005" | Hardened Steel | 0000000 | 00000000 |

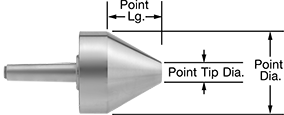

Pipe and Tubing Live Centers

Also known as bull-nose centers, these have a wide head to hold pipe and large-diameter tubing. Use live centers in the tailstock to support the end of a workpiece. With bearings to support their free-turning point, they produce minimal friction between the center and workpiece.

| Morse Taper Number | Max. Workpiece Capacity, lbs. | Point Dia. | Point Tip Dia. | Point Lg. | Shank Lg. | Overall Lg. | Morse Taper Dia. | Max. Speed, rpm | TIR (Total Indicated Runout) Accuracy | Material | Each | |

| 2 | 2,000 | 4" | 1" | 3 29/32" | 2 9/16" | 6 27/32" | 0.7" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 0000000 |

| 3 | 3,800 | 4" | 1" | 3 29/32" | 3 3/16" | 7 15/32" | 0.938" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 000000 |

| 4 | 4,800 | 4" | 1" | 3 29/32" | 4 1/16" | 8 11/32" | 1.231" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 000000 |

| 5 | 4,800 | 4" | 1" | 3 29/32" | 5 3/16" | 9 15/32" | 1.748" | 2,500 | 0.00015" | Hardened Steel | 0000000 | 000000 |

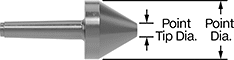

Dead Centers

Insert these in your headstock to support your workpiece when machining between centers. Unlike live centers, dead centers don’t spin freely, so they give you a fixed point to stabilize your material. You can also use them in the tailstock to support the end of the workpiece when friction isn’t a concern. Made of through-hardened 52100 alloy steel—a material originally developed for bearings—these centers have exceptional hardness, strength, and wear resistance. That means you'll have to replace them less often than centers made of low-quality steel. You can also apply high-pressure grease on the point to reduce friction and wear.

Pipe and tubing centers hold large-diameter, hollow workpieces. Also known as bull-nose centers.

Carbide-tipped hardened steel dead centers have better wear resistance than hardened steel dead centers. They’re ideal for high-volume work and holding highly abrasive and hard materials.

Hardened Steel | Carbide-Tipped Hardened Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Morse Taper Number | Point Dia. | Point Tip Dia. | Point Lg. | Overall Lg. | TIR (Total Indicated Runout) Accuracy | Each | Each | ||

Dead Centers | |||||||||

| 1 | 0.475" | __ | 1 3/16" | 3 5/16" | 0.00005" | 000000 | 0000000 | 00000000 | 0000000 |

| 2 | 0.7" | __ | 1 5/8" | 4 3/16" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 0.938" | __ | 2 1/16" | 5 1/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 1.231" | __ | 2 11/16" | 6 3/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 5 | 1.748" | __ | 3 5/16" | 8 1/2" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 6 | 2.494" | __ | 4 1/4" | 11 1/2" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 7 | 3.27" | __ | 5" | 15" | 0.00005" | 0000000 | 000000 | 0000000 | 00000000 |

Dead Centers for Pipe and Tubing | |||||||||

| 2 | 2.13" | 1/2" | 2 13/32" | 5" | 0.00005" | 0000000 | 000000 | 000000 | 00 |

| 3 | 2.75" | 1" | 2 33/64" | 5 3/4" | 0.00005" | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 2.75" | 1" | 2 33/64" | 6 9/16" | 0.00005" | 0000000 | 000000 | 0000000 | 00000000 |

| 5 | 3.5" | 1" | 3 11/64" | 8 3/8" | 0.00005" | 0000000 | 000000 | 000000 | 00 |

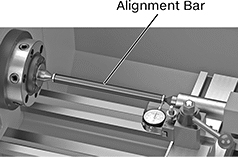

Precision Alignment Bars for Lathes

Turn straight and true—use these bars to confirm that your lathe headstock and tailstock are right inline. Insert the bar between the centers of your headstock and tailstock, then use a variance indicator (not included) on the bar ends. Any difference will register since the bar ends are precision ground to within 0.0002” of each other.

| Overall Lg. | OD | ID | TIR (Total Indicated Runout) Accuracy | Bar Shape | Material | Features | Each | |

Flange End | ||||||||

|---|---|---|---|---|---|---|---|---|

| 12 1/4" | 1" | 0.201" | 0.0002" | Round | Anodized Aluminum | Hardened Steel Bar Ends | 00000000 | 000000 |