Filter by

Shape

Mount Type

Thread Size

Sensitivity

Overall Height

Performance

Magnet Material

Working Orientation

DFARS Specialty Metals

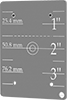

Levels

General Purpose Levels

Mountable Levels

Precision Levels

Long-Distance Levels

Pipe and Conduit Bending Levels

Post Installation Levels