Filter by

Torch Body Type

TIG Welding Type

DFARS Specialty Metals

TIG Industry Number

AWS Material Code

Export Control Classification Number (ECCN)

Head Movement

Length

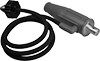

Cable Material

Most Likely Products

All Results

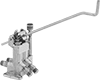

Fastening and Joining

Containers, Storage, and Furniture

Fluid Handling

Material Handling

Electrical

Fabricating and Machining

Lubricating